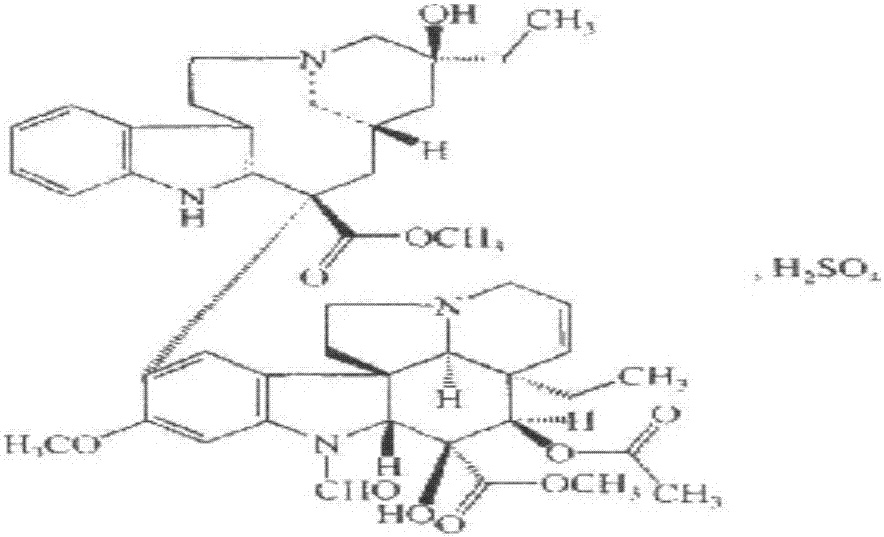

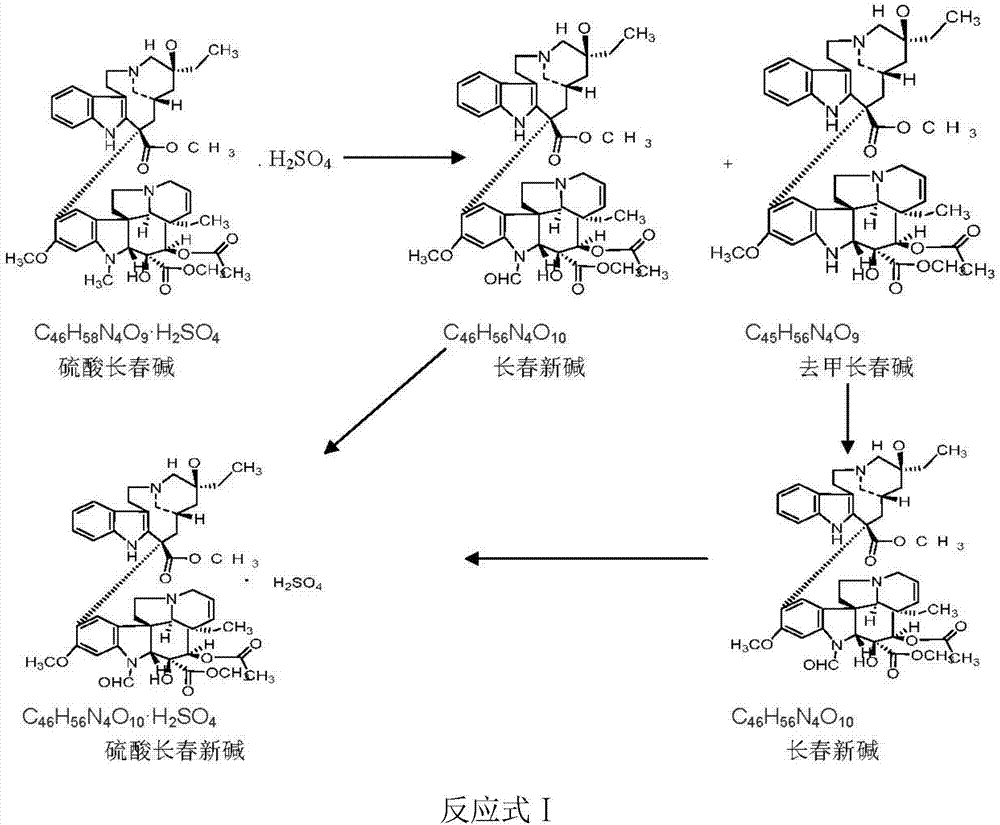

Method for semisynthesis of vincristine sulfate

A technology of vincristine sulfate and vinblastine sulfate, which is applied in the field of semi-synthetic vincristine sulfate, can solve the problems of unfeasible production, low reaction conversion rate, complicated post-processing, etc., and achieves remarkable economic value and high yield , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A method for semi-synthesizing vincristine sulfate, comprising the following steps:

[0054] 1. Refining of crude vinblastine sulfate:

[0055] Weigh 420mL of purified water, add it to a 3L Erlenmeyer flask, and heat to 60-70°C; weigh 210g of crude vinblastine sulfate, add it to the above hot water, dissolve it, and quickly add it to 5040mL of In the water ethanol, a large amount of solids precipitated. After stirring evenly, keep it airtight at room temperature for 1 day; after rapid filtration, wash the filter cake with a small amount of cold absolute ethanol for 2 to 3 times, drain it, and spread it on the Put it in a drying oven tray, put it in a vacuum drying oven, and dry it under reduced pressure (-0.08~-0.1MPa) at 50-60°C for 4 hours to obtain the primary crystallization product of vinblastine sulfate; in the same way, recrystallize the primary crystallization product of vinblastine sulfate Once, refined vinblastine sulfate: 180g (hereinafter referred to as: in...

Embodiment 2

[0069] A method for semi-synthesizing vincristine sulfate, comprising the following steps:

[0070] 1. Refining of crude vinblastine sulfate:

[0071] Weigh 420mL of purified water, add it to a 3L Erlenmeyer flask, and heat to 60-70°C; weigh 210g of crude vinblastine sulfate, add it to the above hot water, dissolve it, and quickly add it to 5040mL of In the water ethanol, a large amount of solids precipitated. After stirring evenly, keep it airtight at room temperature for 1 day; after rapid filtration, wash the filter cake with a small amount of cold absolute ethanol for 2 to 3 times, drain it, and spread it on the Put it in a drying oven tray, put it in a vacuum drying oven, and dry it under reduced pressure (-0.08~-0.1MPa) at 50-60°C for 4 hours to obtain the primary crystallization product of vinblastine sulfate; in the same way, recrystallize the primary crystallization product of vinblastine sulfate Once, refined vinblastine sulfate: 179g (hereinafter referred to as: in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com