Preparation method of zirconia-based metallic ceramic material

A ceramic material and zirconia-based technology, which is applied in the field of preparation of zirconia-based cermet materials, can solve the problems of short service life and low heat exchange efficiency of heat exchange tubes, and achieve the effect of overcoming short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

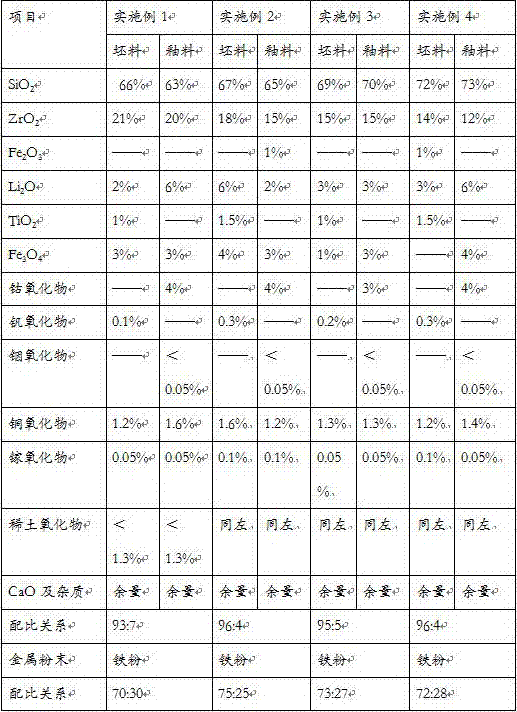

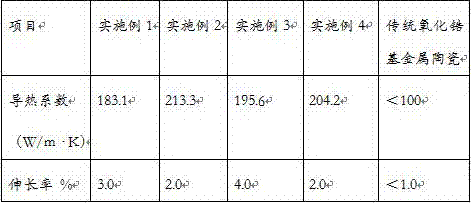

Examples

preparation example Construction

[0026] Further, the preparation method of the ceramic powder comprises the following steps:

[0027] Step 1. The blank is prepared by using the existing technology, and then the surface of the blank is evenly coated with glaze, and then fired into a fired body at a temperature below 1300°C;

[0028] Step 2. Grinding the fired preform together with zinc oxide into a powder with an average particle size of less than 50 μm to obtain ceramic powder, wherein the mass fraction of zinc oxide added is not higher than 3.5% of the mass fraction of the fired body .

[0029] In the zirconia-based cermet material of the present invention, the preparation method of the zirconia-based cermet material comprises the following steps:

[0030] Step 1. Take the designed amount of metal powder and ceramic powder and place them in a high-speed ball mill for mixing and grinding for 2-4 hours. The speed of the high-speed ball mill is 400rad / min, and then put them in a high-speed mixer and mix them e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com