Corn starch concentration waste pulp recovering and torch firing method

A corn starch and pulp recovery technology, applied in the combustion method, combustion type, incinerator, etc., can solve the problem of no concentrated waste syrup recovery and burning, and achieve the effect of preventing air leakage and eliminating stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A kind of cornstarch concentrated waste slurry reclaims spray burning method, comprises the following steps:

[0030] (1) Set up a vertical waste slurry collection tank in the starch workshop; set up a temporary storage tank in the thermoelectric workshop.

[0031] ⑵ Holes are opened on the fins between the boiler water wall 1 tubes.

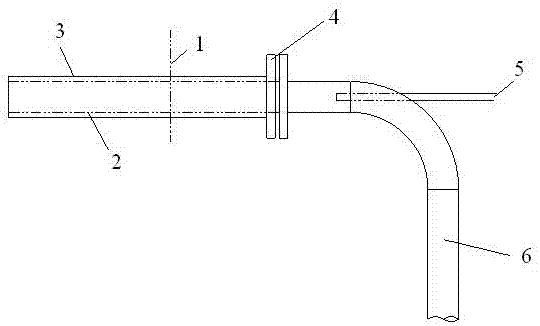

[0032] (3) The front part of the nozzle 2 in the spray gun is provided with a buffer protection sleeve 3, the buffer protection sleeve 3 is fully welded to the fins, and a part of the buffer protection sleeve 3 is placed in the boiler furnace, and the other part is placed in the furnace. Outside the boiler furnace; the nozzle of the buffer protection sleeve 3 placed outside the boiler furnace is welded with a flange 4; the rear part of the nozzle pipe 2 is provided with an atomizing nozzle 5 connected with compressed air, and connected with the thick slurry pipeline 6 (see figure 1 ).

[0033] Wherein: the buffer protection casing 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com