A dynamic photoelastic ultrasound imaging method and system

An ultrasonic imaging system and dynamic photoelastic technology, applied in the field of ultrasonics, can solve problems such as low extinction ratio, large edge energy jitter, and inability to observe ultrasonic signals, so as to improve signal-to-noise ratio, good ultrasonic imaging effect, and improve system sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

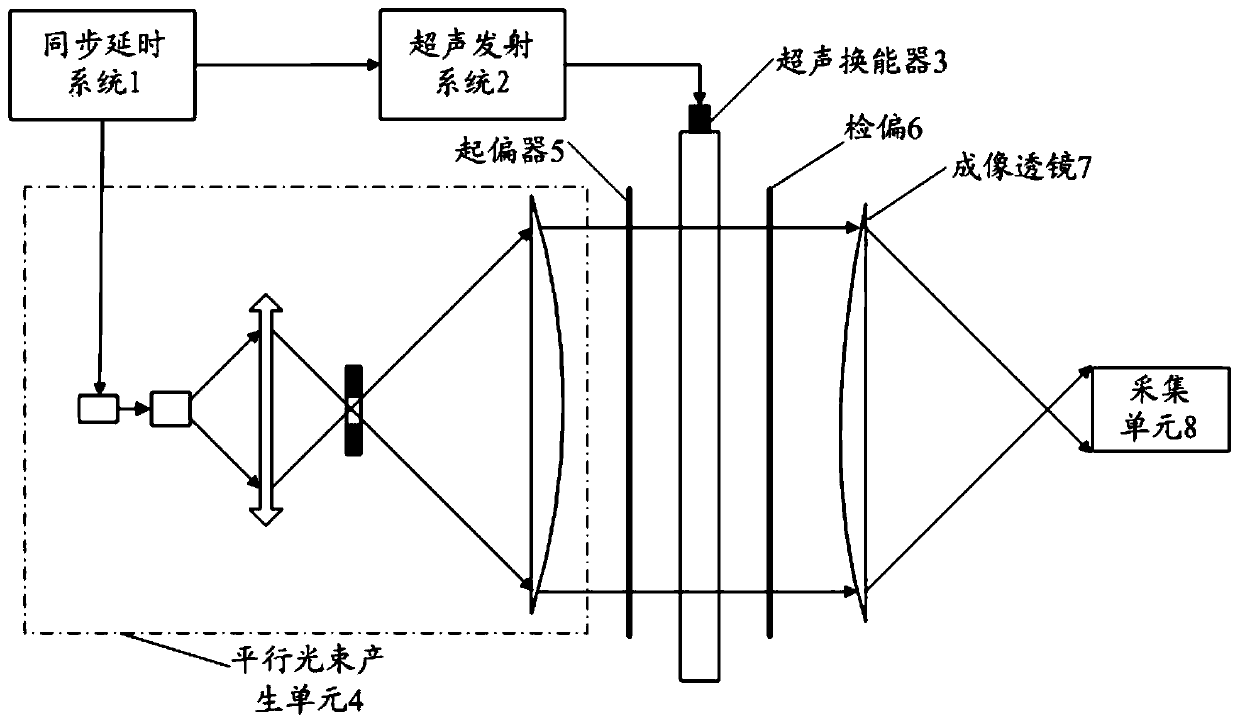

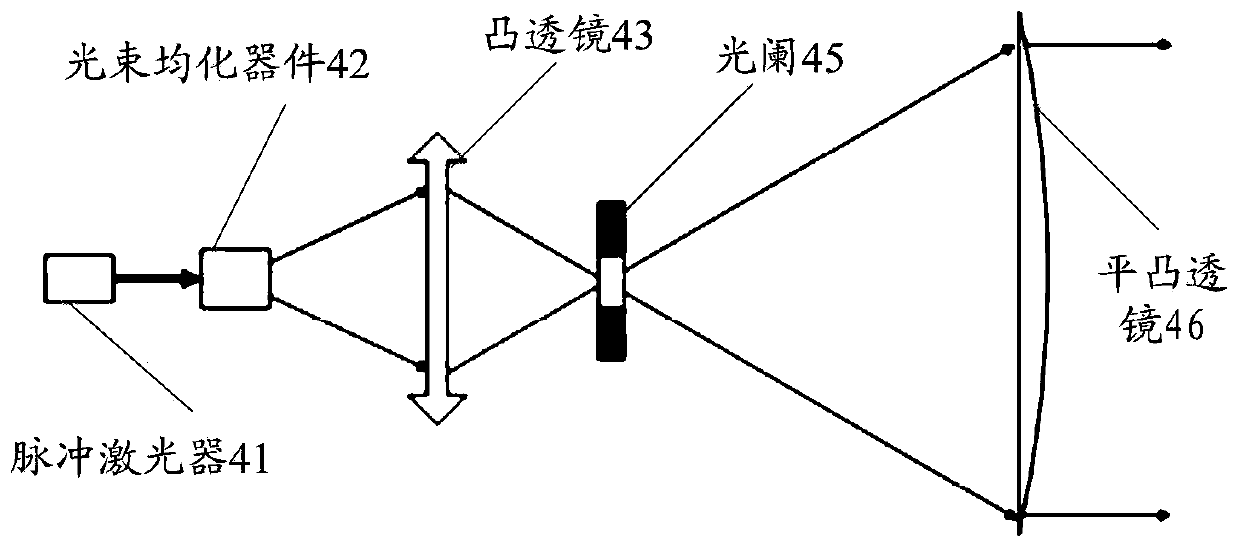

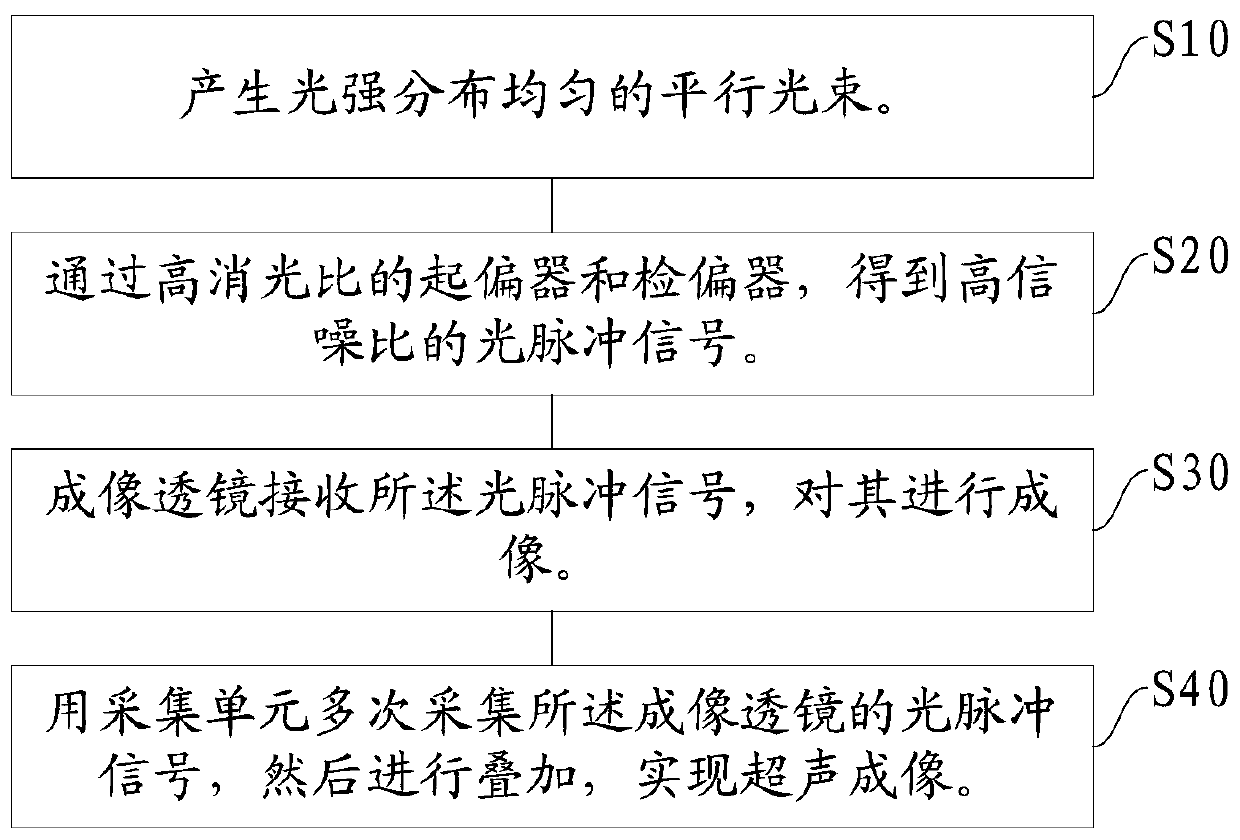

[0072] Examples verify the homogenization and imaging effects of the present invention. In this example, in order to obtain a larger field of view and better explain the problem, the polarizer and analyzer still use traditional resin polarizers. The light source used in the system is a nanosecond-level pulsed laser, which emits green light, and the spatial mode is multi-mode, which is manifested as multiple bright spots. Please refer to figure 1 , the synchronous delay system first sends a trigger signal to the ultrasonic transmitting system, and the ultrasonic transmitting system sends out an electric pulse signal (voltage 1000V) to excite the ultrasonic transducer to generate ultrasound, which propagates in the glass (here the sample is not limited to glass, and can also be other transparent solid). After the ultrasound propagates for a period of time, the synchronous delay system sends a trigger signal to the laser, and the laser emits pulsed laser light, which passes thro...

Embodiment 2

[0075] This embodiment verifies the high sensitivity and the ability to observe weak sound fields of the present invention. The resin polarizer in the system of Example 1 was replaced with a Glan-Taylor prism, and then the voltage of the ultrasonic excitation signal was lowered from 1000V to 10V, at which point the ultrasonic energy became extremely weak. Such as Figure 7 As shown, it is the image collected by using the original resin polarizer. There are only noise spots in the picture, and the ultrasonic signal cannot be distinguished. Figure 8 Shown is the image collected by adopting the solution of the present invention, and ultrasonic fringes can be clearly distinguished. It should be noted that due to the limitation of the clear aperture of the Glan Taylor prism, Figure 8 The streaks captured are only Figure 6 part of the field of view.

[0076] Therefore, it can be seen that the present invention can significantly improve the system sensitivity, realize better u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com