Preparation method of pre-activated lithium-rich manganese-based positive electrode material used for lithium ion battery

A lithium-ion battery, lithium-rich manganese-based technology, applied in the direction of battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of easily damaged material structure, deteriorated material cycle stability, deteriorated material stability, etc., to achieve process Simple and feasible, increased safety and cycle stability, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

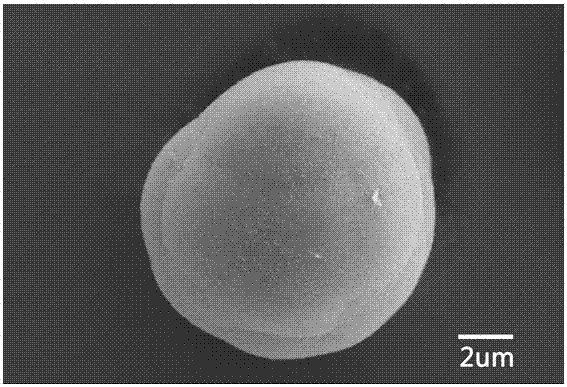

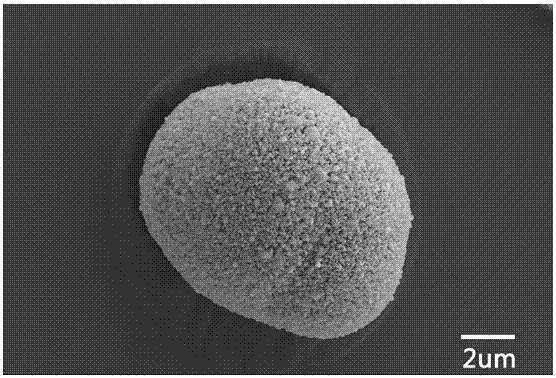

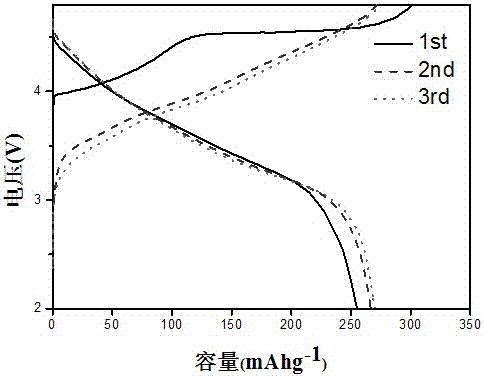

[0023] Specific Embodiment 1: This embodiment records a method for preparing a pre-activated lithium-rich manganese-based positive electrode material for lithium-ion batteries. The specific steps of the method are as follows:

[0024] Step 1: Prepare a nickel-cobalt-manganese precursor by co-precipitation, then uniformly mix it with lithium salt, and calcinate at a high temperature to obtain a lithium-rich manganese-based positive electrode material, wherein the molar ratio of lithium salt to nickel-cobalt-manganese precursor is 1.03~1.17:1, high-temperature calcination is specifically: at a heating rate of 5℃ / min, from room temperature to 300~500℃, constant temperature for 3~6h, and then at a heating rate of 5℃ / min to 650~950℃, Constant temperature for 8-15 hours, then naturally cool to room temperature;

[0025] Step 2: Add the lithium-rich manganese-based positive electrode material prepared in step 1 into the solvent, and stir with a magnetic stirrer for 5-30 minutes, so t...

specific Embodiment approach 2

[0027] Specific embodiment two: the preparation method of a lithium-ion battery pre-activated lithium-rich manganese-based positive electrode material described in specific embodiment one, in step one, the molecular formula of the lithium-rich manganese-based positive electrode material is xLi 2 MnO 3 ·(1-x)LiMO 2 , where M=Ni, Co, Mn, 0

specific Embodiment approach 3

[0028] Specific embodiment three: the preparation method of a kind of pre-activated lithium-rich manganese-based positive electrode material for lithium-ion batteries described in specific embodiment one, in step two, the solvent is water, alcohol, ethylene glycol, isopropanol or One of N-methylpyrrolidone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com