Carbon-based platinum-silver-palladium ternary alloy catalyst and preparation method thereof

A ternary alloy and catalyst technology, applied in electrical components, nanotechnology for materials and surface science, structural parts, etc., can solve problems such as low cost, and achieve the effect of simple and easy synthesis method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

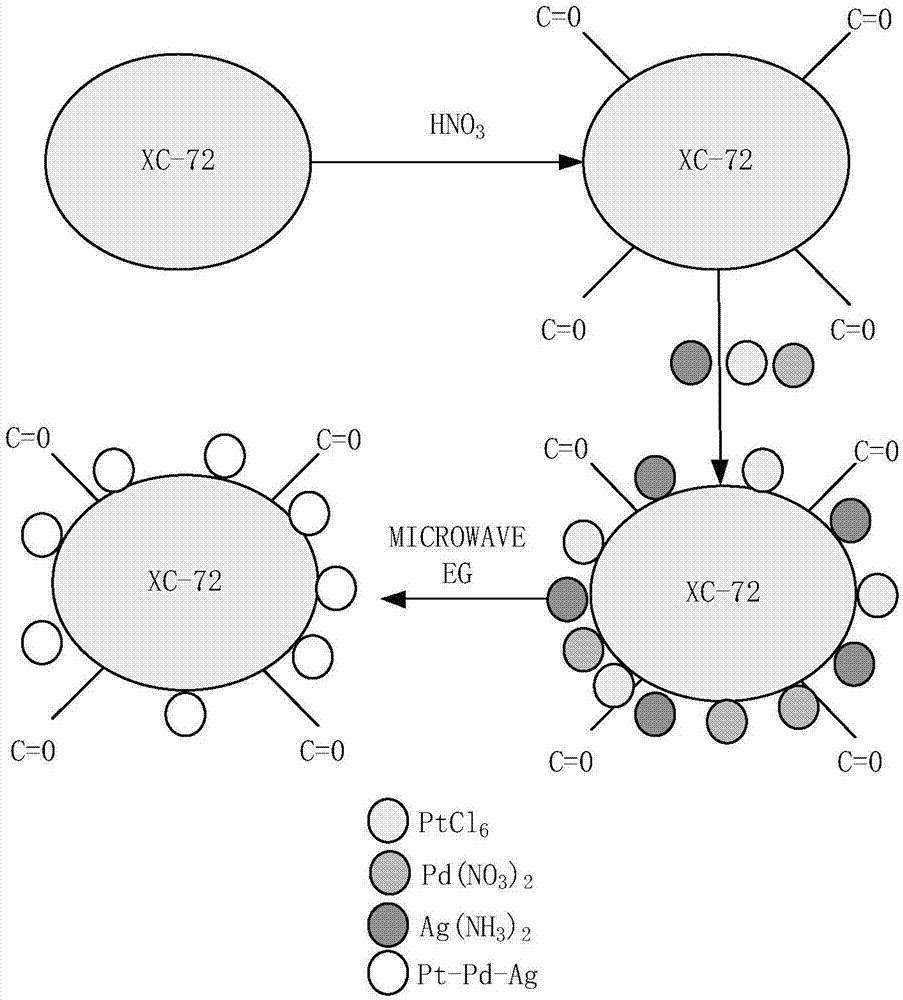

[0037] 1) The carbon black is acidified with nitric acid under the conditions of condensation and reflux at a temperature of 120°C: a quantitative amount of carbon black is added to a three-port container, and then an excessive amount of concentrated nitric acid (commercially purchased analytically pure, mass fraction 68%) 120 The solution was stirred for 1 hour under the condition of an oil bath. Raise the temperature to 1000°C, keep it warm for 10 hours, then cool the solution, centrifugally filter, wash until neutral, dry, and grind for later use. At this time, the carbon black is hollow carbon black. The volume of the prepared hollow carbon black is about 30% larger than that of the raw carbon black.

[0038] 2) Preparation of Alloy Pd-Pt-Ag / C Catalyst

[0039] First weigh 100mg of hollow carbon black and put it into a beaker, add 50ml of ethylene glycol solution (a mixture of ethylene glycol and water in a 2:1 mass ratio), ultrasonicate for 20min, and pipette an appropria...

Embodiment 2-7

[0043] Adopt the same operation as Example 1, change the addition ratio of silver ammonia solution, chloroplatinic acid solution, palladium nitrate solution and make Pt10Ag80Pd10 / C, Pt20Ag70Pd10 / C, Pt30Ag50Pd20 / C, Pt40Ag40Pd20 / C, Pt50Ag30Pd20 / C, Pt30Ag60Pd10 / C C catalyst.

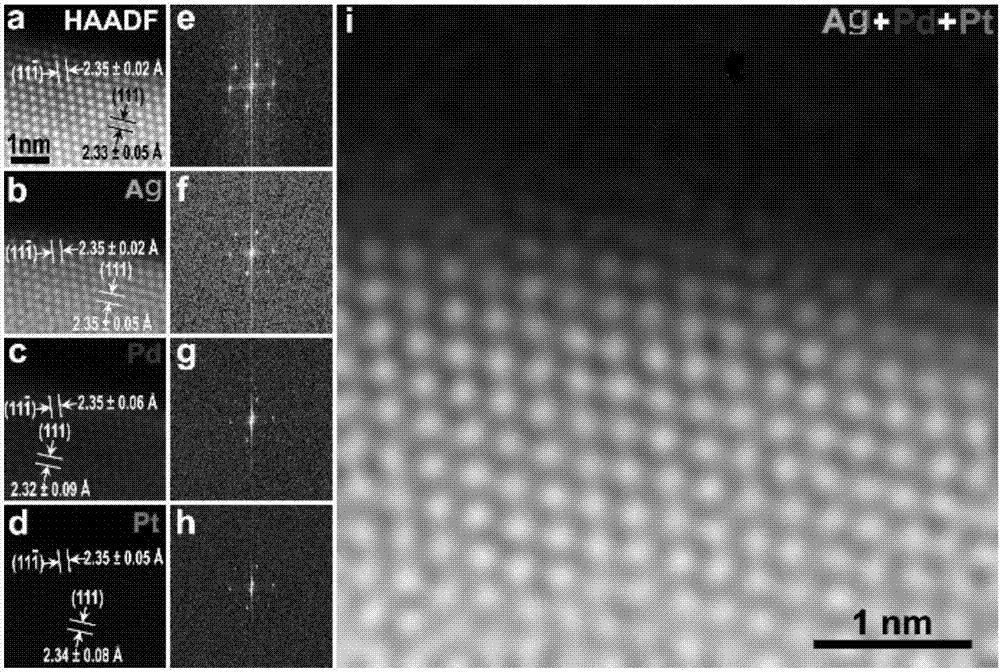

[0044] Through TEM and SEM tests, it is known that the particle size of the metal particles is about 6.4nm, and they are evenly loaded on the surface of the carbon black carrier, see Figure 6 . Through XRD and XPS tests, it can be seen that the synthesized metal nanoparticles are alloy solid solution with silver as solvent and platinum and palladium as solute.

[0045] theoretical calculation

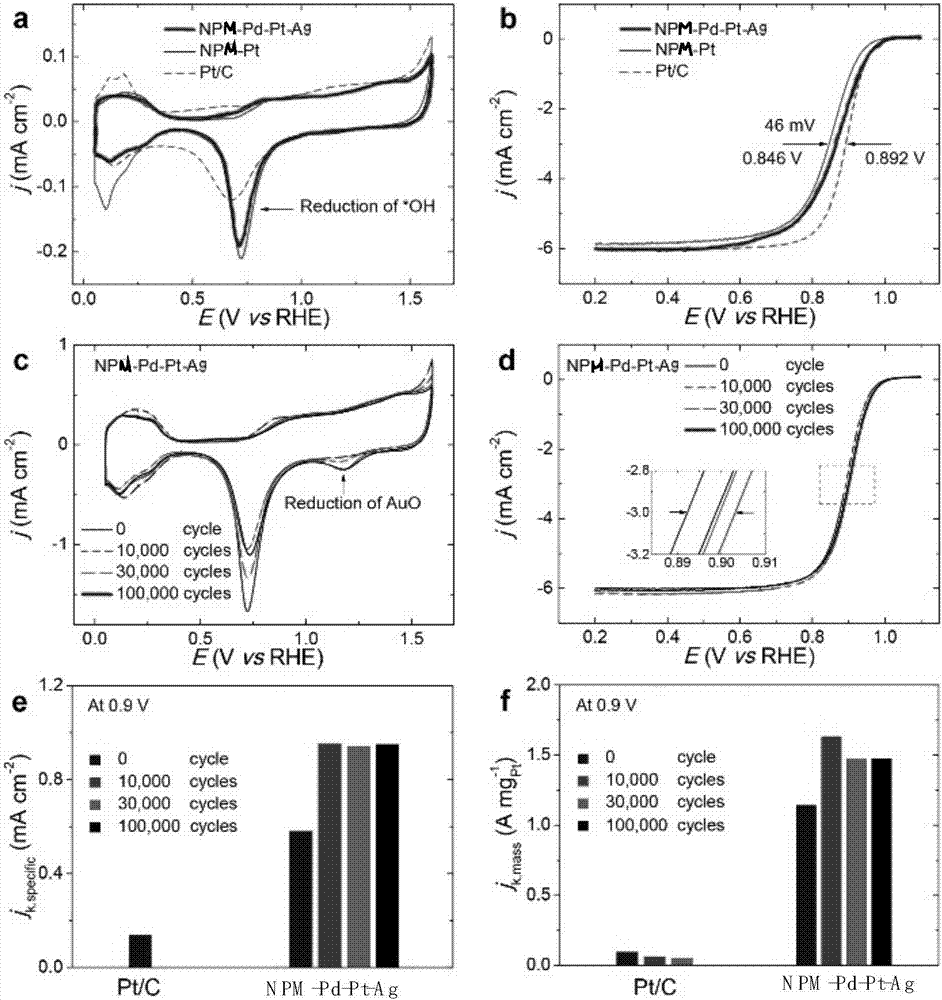

[0046] Figure 5 Schematic diagram for theoretical calculation of ORR activity on Pt-Pd-Ag(111) and Pt(111) surfaces. The activity was shown by calculating the electron transfer number for oxygen reduction. On the basis of the RDE of the rotating disc electrode, test the LSV curves at different speeds, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com