Lithium-ferrous disulfide battery and assembly method thereof

A ferrous disulfide and assembly method technology, applied in the internal connection of lithium-ferrous disulfide battery, lithium-ferrous disulfide battery and its assembly field, can solve the complicated resistance welding process, battery safety hazards, and poor resistance welding problems such as high rate, to achieve the effect of realizing automated mass production, reducing production costs, and avoiding high defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

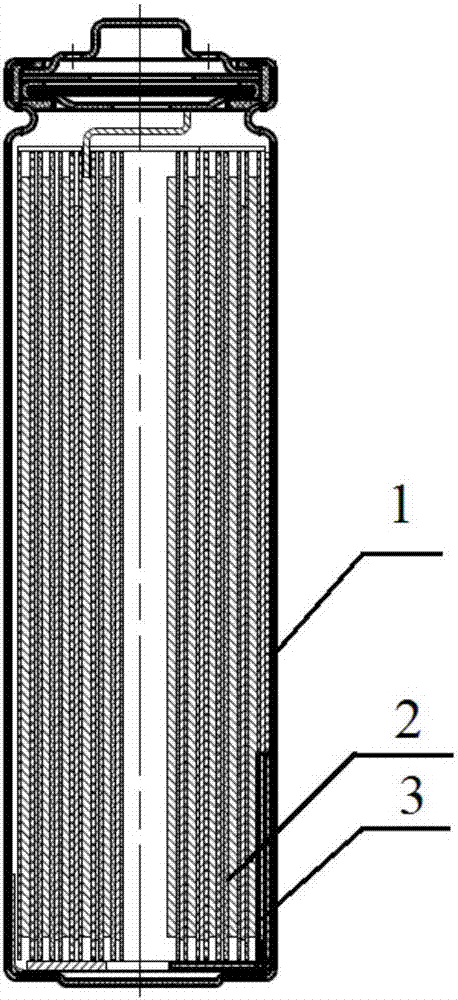

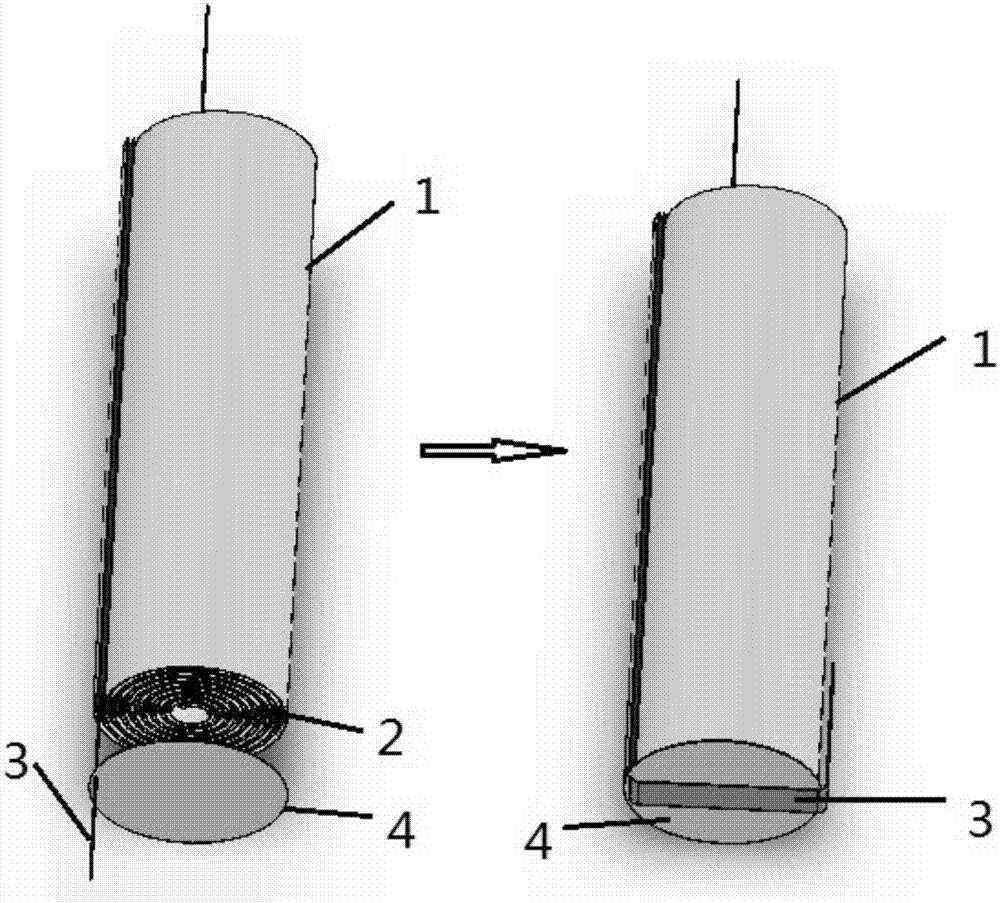

[0027] A lithium-ferrous disulfide battery includes a wound cell 2 and a casing 1. The negative electrode tab 3 exposed outside the wound cell 2 is in contact with the side wall of the casing 1. Among them, the negative pole lug 3 is a stainless steel strip, which is 10 mm longer than the diameter of the wound cell 2, and the outer shell is a nickel-plated steel shell.

[0028] The assembly steps are as follows:

[0029] Pass the negative electrode tab 3 of the wound cell 2 through the square hole of the 0.1mm thick PP insulation gasket 4 and bend it at 90°. The diameter of the insulation gasket 4 is the same as the diameter of the wound cell 2. The square hole The size is the same as the size of the negative electrode tab 3; then the extra tab at the bottom of the battery core is bent 90° against the battery core, and finally the battery core is placed in the case 1, which completes the negative tab tab 3 and the case 1 connection.

[0030] According to conventional methods and ot...

Embodiment 2

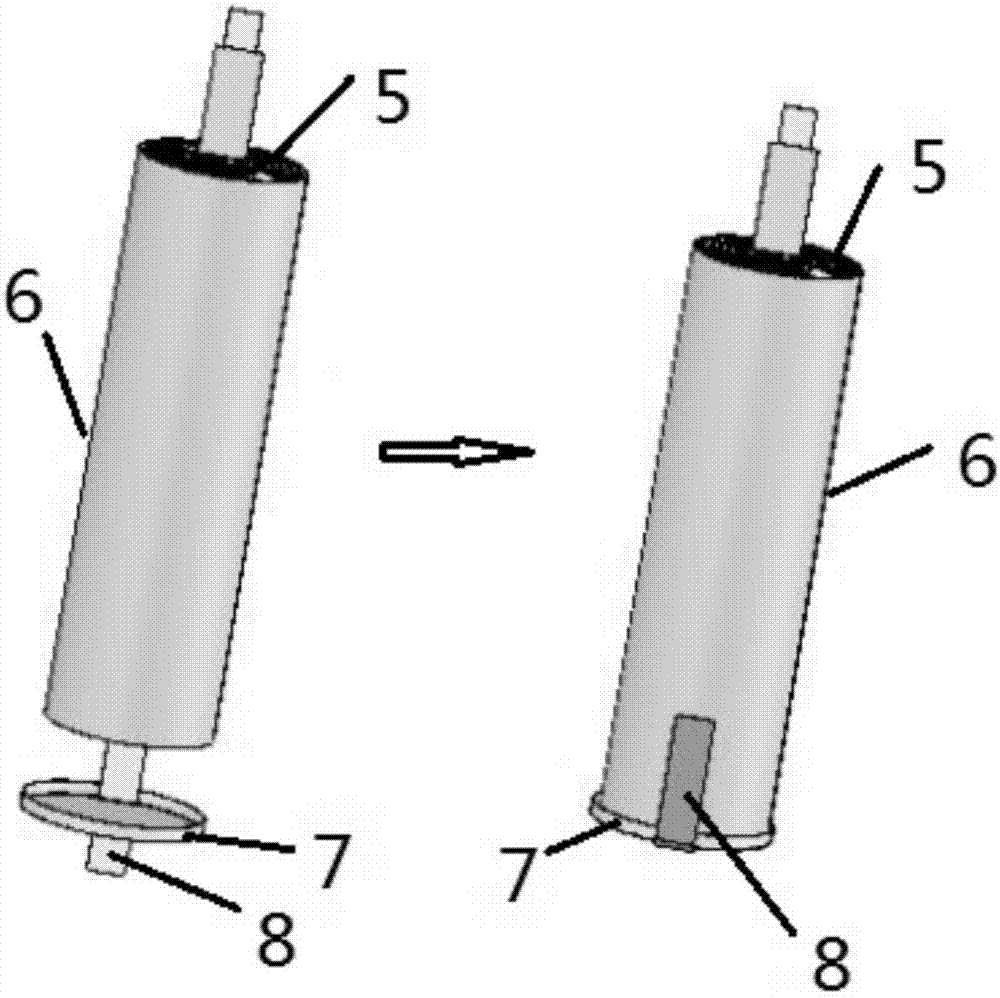

[0032] A lithium-ferrous disulfide battery includes a wound cell 5 and a casing 6. The negative electrode tab 8 exposed outside the wound cell 5 is in contact with the side wall of the casing 6. Among them, the negative pole lug 8 is a copper strip, which is 15 mm longer than the diameter of the wound cell 5, and the outer shell 6 is a nickel-plated steel shell.

[0033] The assembly steps are as follows:

[0034] Pass the negative electrode tab 8 of the wound cell 5 through the square hole of the 0.5mm thick PET insulation cover 7 and bend it at 90°. The diameter of the insulation cover 7 is the same as the diameter of the wound cell 5. The square hole The size of the battery is the same as the size of the negative electrode tab 8; then the extra tab at the bottom of the battery cell is bent 90° against the battery core, and finally the battery core is placed in the case 6, which completes the negative tab tab 8 and the case 6's connection.

[0035] According to conventional metho...

Embodiment 3

[0037] A lithium-ferrous disulfide battery includes a wound electric core and a casing, and the negative electrode tab exposed outside the wound electric core is in contact with the side wall of the casing. Among them, the negative pole lug is a nickel-plated steel strip, which is 13mm longer than the diameter of the wound cell, and the outer shell is a nickel-plated steel shell.

[0038] The assembly steps are as follows:

[0039] Pass the negative electrode tab of the wound cell through the square hole of the 0.3mm thick PVC insulating sleeve and bend it at 90°. The diameter of the insulation sleeve is the same as the diameter of the wound cell, and the size of the square hole is the same as that of the negative electrode. The size of the lugs is the same; then the extra lugs at the bottom of the cell are bent 90° against the cell, and finally the cell is placed in the shell to complete the connection between the negative pole and the shell.

[0040] According to conventional meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com