An efficient protein polymerization method

A protein and high-efficiency technology, applied in the field of biomedicine, can solve the problems of cumbersome removal process and long time, and achieve the effects of short polymerization reaction time, reduced ratio and high polymerization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

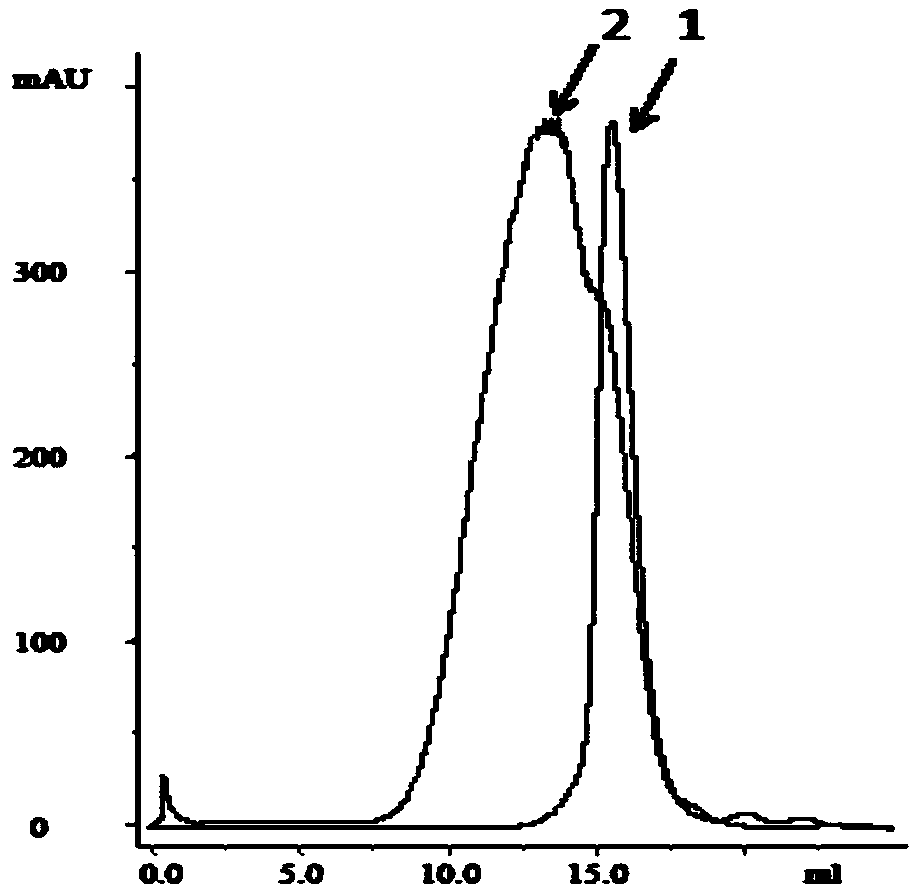

Image

Examples

Embodiment 1

[0045] Embodiment 1 prepares polyprotein with anion exchange resin

[0046] (1) Pretreatment of the medium: Take 10ml of DEAE agarose (anion exchange resin) and add 20ml of 0.02M glutaraldehyde to react with possible groups on the solid phase medium that can react with aldehyde groups for 1 hour. Add 20ml of 0.8M sodium borohydride to reduce the resulting product and excess glutaraldehyde, centrifuge at 1000r / min and discard the supernatant, and repeat washing with buffer 5 times. The unreacted polyaldehydes were terminated, polyaldehydes and reducing agents in the system were washed away with 15 mM phosphate buffer, and the pH of the solid phase medium was adjusted to 9.

[0047] (2) Pretreatment of polyaldehyde-based molecules: glutaraldehyde and glycerol are mixed according to the molar ratio of 1:40, the volume after mixing is 15ml, and 10 microliters of 1.5M hydrochloric acid are added for catalysis, so that the pH of the solution is 6. The reaction temperature is 40°C, ...

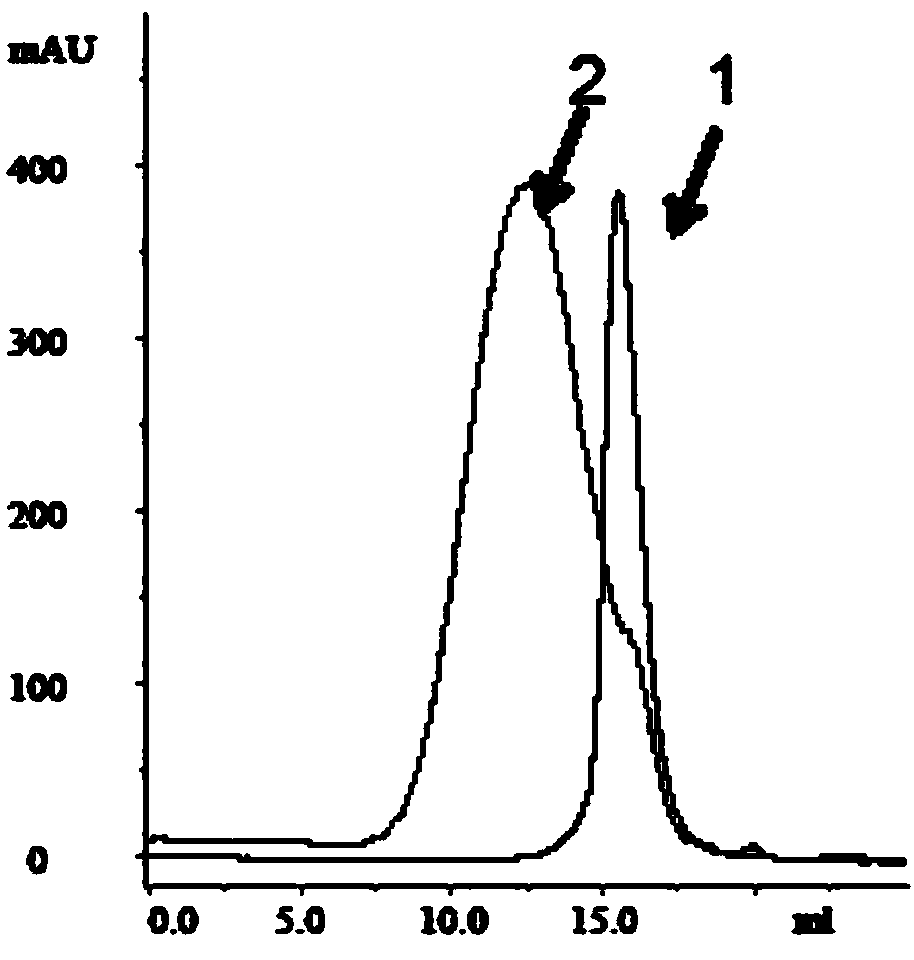

Embodiment 2

[0052] Embodiment 2 prepares protein with cation exchange resin

[0053] (1) Pretreatment of the medium: Take 10ml of H-type cation exchange resin and add 20ml of 0.05M malondialdehyde to react with possible groups on the solid phase medium that can react with aldehyde groups. After reacting for 0.5 hours, add 20ml of 0.5M dimethylaminoborane, reduce the resulting product and excess malondialdehyde, centrifuge at 1000r / min and discard the supernatant, and repeat washing with 15mM HEPES buffer 5 times. And stop the unreacted polyaldehyde, wash away other residues in the system with buffer, and adjust the pH of the solid phase medium to 6.

[0054] (2) Pretreatment of polyaldehyde-based molecules: MDA and ethylene glycol are mixed according to the molar ratio of 1:60, the final volume is 15ml, and 10 microliters of 1.5M sulfuric acid are added for catalysis, so that the pH of the solution is 5.5 , the reaction temperature was 4° C., and the reaction time was 80 min. .

[0055...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com