Layered covering method for soil on surface of tree holes

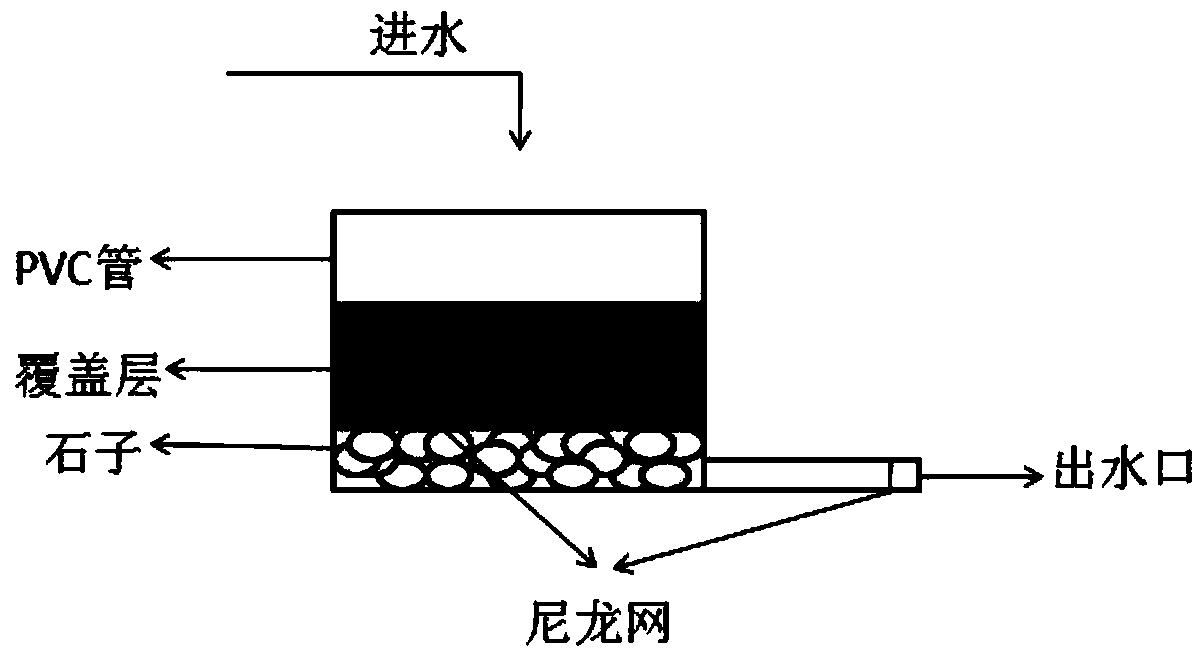

A surface soil and soil technology, applied in the field of landscaping, can solve problems such as poor water holding capacity, achieve the effect of maintaining water, benefiting the natural degradation process, and increasing soil nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1 landscaping waste pretreatment

[0073] 1. Collection and classification of landscaping waste

[0074] Collection of trimmings (thinnings) of trees, shrubs and herbaceous plants, lawn trimmings, fallen leaves, branches, discarded grass flowers and weeds in gardens and flower beds produced in the natural or maintenance process of green plants in urban green land or suburban woodland The collected wastes are divided into three categories through source pruning classification and manual classification:

[0075] Class A: tree branches with a diameter ≥ 20cm; Class B: tree branches with a diameter < 20cm; Class C: leaves and grass and flower prunings.

[0076] 2. Crushing of waste

[0077] 2-1) Shredder treatment of Class A waste

[0078] Use a pulverizer (Henan Hongyun Woodworking Machinery Manufacturing Factory) to pulverize tree branches with a diameter ≥ 20 cm into wood fragments with a particle size of 3-10 cm and a thickness of 5-15 mm.

[0079] 2-2) P...

Embodiment 2

[0084] The composting treatment of embodiment 2 landscaping waste

[0085] 1. Mix finely divided branches with a particle size of 0-1 cm and leaves-flowers and grass scraps with a particle size of ≤0.5 cm and collected landscaping waste to make compost raw materials;

[0086] 2. Add urea to the compost raw materials, adjust the C / N ratio of the raw materials to 30 (the C / N ratio is usually 20-35); then add fermentation bacteria to the compost raw materials (Beijing Jingpuyuan Biological Engineering Co., Ltd.) and water, mix evenly to make compost waste materials, and then place the compost waste materials on the cement floor of the greenhouse with a space height ≥ 4m, and stack them into a pile with a bottom width of 1-1.5m, a height of 1-1.5m, and a length depending on the situation. Trapezoidal heap for composting; the weight ratio of the fermentation agent to the composting raw material (dry weight) is 0.5:100 (usually 0.1-1:100); the moisture content of the composting wast...

Embodiment 3

[0090] The carbonization treatment of embodiment 3 landscaping waste

[0091] Put the carbonized raw materials prepared in the examples (i.e. finely chopped branches with a particle size of 1-3 cm) into a carbonization furnace (Zhengzhou Chaoyuan Machinery Equipment Co., Ltd.), heat up to 160°C, and keep the temperature at 160°C. The moisture in the carbonized raw material is evaporated, and the carbonized raw material is dried; after drying for 6 hours (usually 5-8 hours), continue to heat up to 240°C (usually 160-280°C), and keep the temperature at 240°C (usually 160- Under the condition of 280°C), the carbonized raw materials are subjected to the first stage of carbonization treatment, so that the landscaping waste undergoes thermal decomposition reaction; after the first stage of carbonization treatment for 3h (usually 2-4h), continue to heat up to 500°C (usually 300-650°C), under the condition of keeping the temperature at 500°C (usually 300-650°C), carry out the second-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com