Three-layer wood-plastic floor board and preparation method thereof

A technology of wood-plastic flooring and flooring, which is applied in the direction of chemical instruments and methods, layered products, and synthetic resin layered products. sex, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

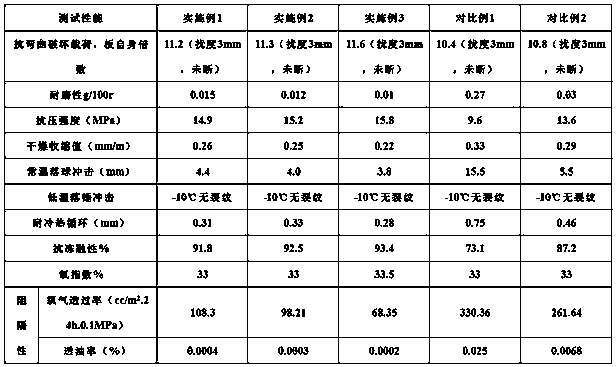

Examples

Embodiment 1

[0026] A three-layer wood-plastic floor is composed of a bottom floor, a middle floor and a top floor;

[0027] The top layer of the floor is prepared from the following raw materials in parts by mass: 100 parts of PVC powder, 22 parts of two-component polyurethane elastomer, 80 parts of plant fiber, 6 parts of isopropyl tris(dioctylpyrophosphoryloxy) titanate part, 20 parts of flame retardant plasticizer, 3 parts of heat stabilizer, 1 part of antioxidant, 1 part of antiaging agent and 0.5 part of coloring agent; Described flame retardant plasticizer is made of chlorinated paraffin-70 and tetrabromo Phthalate is composed of 1.5:1 by mass ratio;

[0028] The middle layer of the floor is made of the following raw materials in parts by mass: 100 parts of PVC powder, 40 parts of glass fiber, 3 parts of silane coupling agent KH550, 15 parts of plasticizer, 4 parts of heat stabilizer and 1 part of lubricant;

[0029] The bottom layer of the floor is made of the following raw materi...

Embodiment 2

[0036] A three-layer wood-plastic floor is composed of a bottom floor, a middle floor and a top floor;

[0037] The top layer of the floor is prepared from the following raw materials in parts by mass: 100 parts of PVC powder, 28 parts of two-component polyurethane elastomer, 100 parts of plant fiber, 8 parts of isopropyl tris(dioctylpyrophosphoryloxy) titanate 3 parts, 30 parts of flame-retardant plasticizers, 5 parts of heat stabilizers, 3 parts of antioxidants, 3 parts of anti-aging agents and 1.5 parts of coloring agents; Phthalate esters are composed of 3:1 by mass ratio;

[0038] The middle layer of the floor is made of the following raw materials in parts by mass: 100 parts of PVC powder, 60 parts of glass fiber, 5 parts of silane coupling agent KH550, 20 parts of plasticizer, 6 parts of heat stabilizer and 3 parts of lubricant;

[0039] The bottom layer of the floor is made of the following raw materials in parts by mass: 100 parts of PVC powder, 35 parts of two-compo...

Embodiment 3

[0046] A three-layer wood-plastic floor is composed of a bottom floor, a middle floor and a top floor;

[0047] The top layer of the floor is prepared from the following raw materials in parts by mass: 100 parts of PVC powder, 25 parts of two-component polyurethane elastomer, 90 parts of plant fiber, 7 parts of isopropyl tris(dioctylpyrophosphoryloxy) titanate 2 parts, 25 parts of flame retardant plasticizers, 4 parts of heat stabilizers, 2 parts of antioxidants, 2 parts of antiaging agents and 1 part of colorants; Phthalate is composed of 2:1 by mass ratio;

[0048] The middle layer of the floor is made of the following raw materials in parts by mass: 100 parts of PVC powder, 50 parts of glass fiber, 4 parts of silane coupling agent KH550, 18 parts of plasticizer, 5 parts of heat stabilizer and 2 parts of lubricant;

[0049] The floor bottom layer is prepared from the following raw materials in parts by mass: 100 parts of PVC powder, 33 parts of two-component polyurethane el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com