Preparation method of anti-reflection film

A technology of anti-reflection film and mixed liquid, applied in the direction of coating, etc., can solve the problem that the refractive index of the anti-reflection film cannot be lowered too low, and it can only be reduced to about 2% to 4%, and the film cannot be used normally. and other problems, to achieve the effect of fast corrosion rate, low cost and no pollution discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

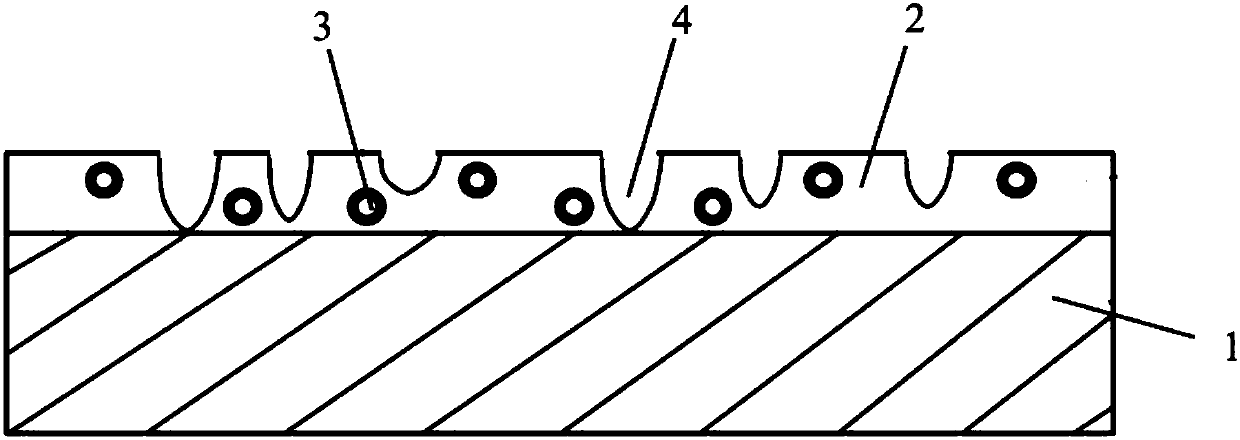

Image

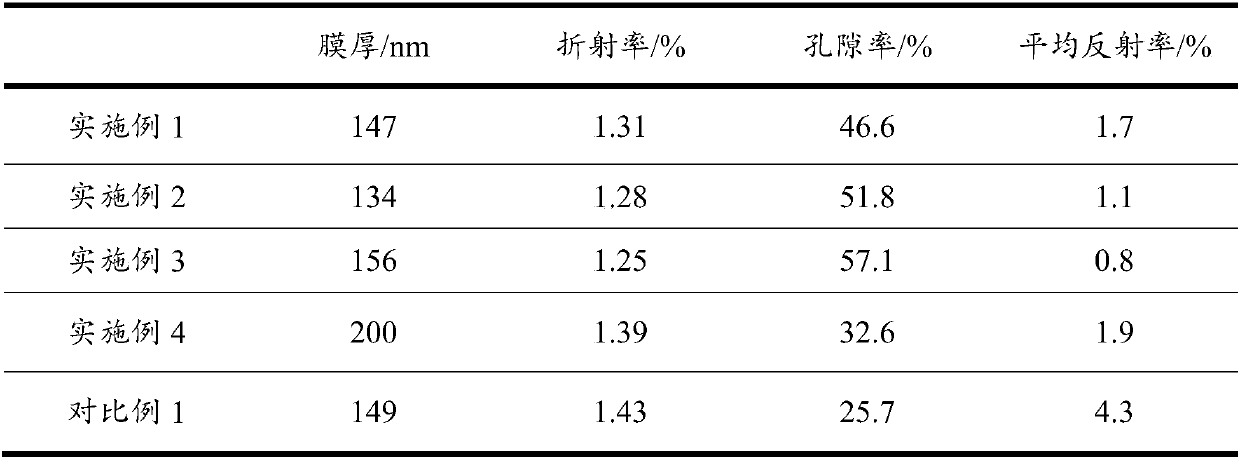

Examples

Embodiment 1

[0038] (1) Weigh anhydrous ethanol, tetraethyl orthosilicate, and KH560 with a molar ratio of 1:10.6:3.7 and mix and stir evenly under the action of a magnetic stirrer to obtain a mixed solution A; weigh a mass with a molar ratio of 0.002:11 Mix nitric acid and deionized water with a fraction of 10% under the action of a magnetic stirrer to obtain a mixed solution B; slowly drop the mixed solution B into the mixed solution A with a dropper, and continuously stir the mixed solution A during the dropping process , until the two are completely mixed, and continue to stir for 5 hours, and let stand for 1 day to obtain a silica sol.

[0039] (2) Weigh 3.6g of polyacrylic acid with a molecular weight of 2000 and dissolve it in 20mL of ammonia water. After the polyacrylic acid is completely dissolved, a mixed solution C is obtained. Add all the mixed solution C to 300mL of absolute ethanol and mix evenly with magnetic stirring After that, add 0.2mL tetraethyl orthosilicate dropwise w...

Embodiment 2

[0045] (1) Weigh tetraethyl orthosilicate, absolute ethanol, and KH570 with a molar ratio of 1:12:2.3, and mix and stir evenly under the action of a magnetic stirrer to obtain a mixed solution A; weigh a molar ratio of 0.004:15 Mix hydrochloric acid and deionized water with a mass fraction of 30% under the action of a magnetic stirrer to obtain a mixed solution B; slowly drop the mixed solution B into the mixed solution A with a dropper, and continuously stir the mixed solution during the dropping process A, until the two are completely mixed, and continue to stir for 5 hours, and let stand for 1 day to obtain silica sol.

[0046] (2) Weigh 3.6g of polyacrylic acid with a molecular weight of 2000 and dissolve it in 20mL of ammonia water. After the polyacrylic acid is completely dissolved, a mixed solution C is obtained. Add all the mixed solution C to 300mL of absolute ethanol and mix evenly with magnetic stirring After that, add 0.2mL tetraethyl orthosilicate dropwise with a ...

Embodiment 3

[0052] (1) Weigh tetraethyl orthosilicate, absolute ethanol, and KH550 with a molar ratio of 1:9.4:5 and mix and stir evenly under the action of a magnetic stirrer to obtain a mixed solution A; weigh the acid with a molar ratio of 0.01:20 Catalyst (1 / 3 mass fraction is 30% hydrochloric acid and 2 / 3 mass fraction is 10% nitric acid mixing) and deionized water, mix and stir under the effect of magnetic stirrer, obtain mixed solution B; Mixed solution B is used The dropper was slowly added dropwise to the mixed solution A, and the mixed solution A was continuously stirred during the dropping process until the two were completely mixed, and the stirring was continued for 5 hours, and the silica sol was obtained by standing still for 1 day.

[0053] (2) Weigh 3.6g of polyacrylic acid with a molecular weight of 2000 and dissolve it in 20mL of ammonia water. After the polyacrylic acid is completely dissolved, a mixed solution C is obtained. Add all the mixed solution C to 300mL of abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com