Preparation method of superfine-structure graphite used for electric spark machining

A fine structure, electric spark technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problem that the product cannot meet the needs of users, and achieve the effect of improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

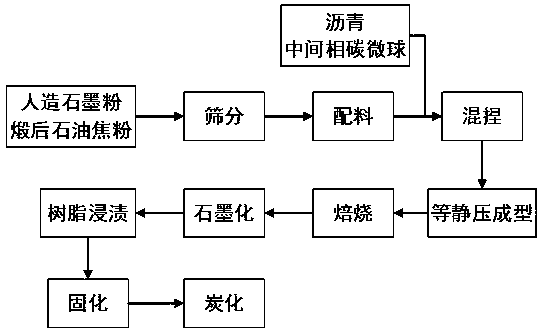

Method used

Image

Examples

Embodiment

[0033] ① Fully mix 100kg of pitch and 100kg of mesocarbon microspheres with a particle size of less than 5μm under heating, and the heating temperature is 250°C.

[0034] ② Fully mix 250kg of calcined petroleum coke powder with a particle size of less than 5μm and 50kg of artificial graphite powder with a particle size of less than 5μm.

[0035] ③Knead 200kg of the mixture in step ① and 300kg of the mixture in step ②. The kneading process needs to be heated. The heating temperature is 200°C and the kneading time is 90min.

[0036] ④Transfer all the raw materials kneaded in step ③ to the isostatic pressing mold, evacuate it to 20KPa, and then move it to the isostatic pressing machine for compression molding. 10 minutes, then release the pressure to 70MPa at a pressure relief rate of 15MPa / min, and stabilize the pressure for 5 minutes; then release the pressure to 40MPa at a pressure relief rate of 10MPa / min, and stabilize the pressure for 5 minutes; finally release the pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com