Method for producing sec-butyl alcohol through continuous hydrolysis

A technology for catalyzed hydrolysis of sec-butanol, applied in hydrolysis preparation, separation methods, chemical instruments and methods, etc., can solve the problem of low conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

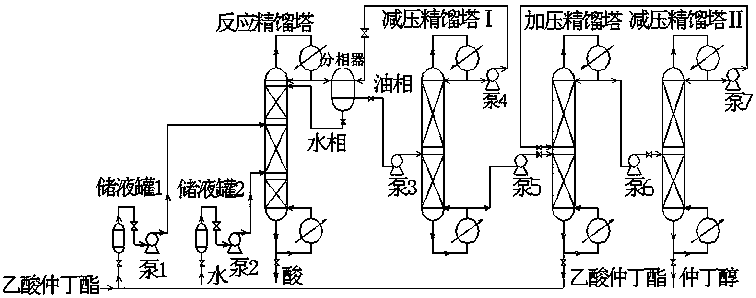

Method used

Image

Examples

Embodiment 1

[0029] The feed molar ratio of sec-butyl acetate to water in the reactive distillation column is 2, the reflux ratio is 2, the operating pressure is 0.2MPa, and the temperature is 100°C; the operating pressure in the vacuum distillation column is 5kPa, and the reflux ratio is 2 , The operating pressure in the pressurized rectification tower is 0.6MPa, and the reflux ratio is 2.

[0030] In this example, the hydrolysis conversion rate of sec-butyl acetate was 43.17%, the purity of sec-butanol was 99.97%, and the yield of sec-butanol was 90.82%.

Embodiment 2

[0032] The feed molar ratio of sec-butyl acetate to water in the reactive distillation column is 5, the reflux ratio is 8, the operating pressure is 0.3MPa, and the temperature is 110°C; the operating pressure in the vacuum distillation column is 10kPa, and the reflux ratio is 5 , The operating pressure in the pressurized rectification tower is 1.0MPa, and the reflux ratio is 5.

[0033] In this example, the hydrolysis conversion rate of sec-butyl acetate was 66.53%, the purity of sec-butanol was 99.97%, and the yield of sec-butanol was 94.40%.

Embodiment 3

[0035] The feed molar ratio of sec-butyl acetate to water in the reactive distillation column is 5, the reflux ratio is 10, the operating pressure is 0.5MPa, and the temperature is 120°C; the operating pressure in the vacuum distillation column is 50kPa, and the reflux ratio is 8 , The operating pressure in the pressurized rectification tower is 1.3MPa, and the reflux ratio is 8.

[0036] In this example, the hydrolysis conversion rate of sec-butyl acetate was 70.88%, the purity of sec-butanol was 99.93%, and the yield of sec-butanol was 95.07%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com