A dry desulfurization purification process for ethylene-rich gas

A dry desulfurization and ethylene-enriching technology, which is applied in separation methods, gas treatment, chemical instruments and methods, etc., can solve the problems of desulfurization, arsenic removal, and ethylene yield reduction without detailed introduction of desulfurization methods, etc., to achieve Improve the conversion rate of hydrolysis, reduce the loss of ethylene, and reduce the effect of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

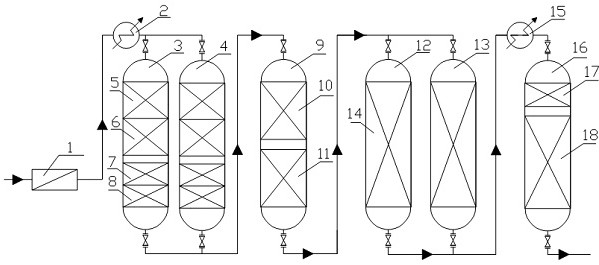

Embodiment 1

[0022] The dry desulfurization and purification process of ethylene-rich gas in a refinery in Shandong is shown in the attached figure 1 As shown, the content of ethylene-rich gas and main impurities is shown in Table 1. This comes from upstream 4000Nm 3 / h The ethylene-rich gas first passes through the coalescing filter 1 for rough dehydration, is heated to 80°C by the steam heater 2, and enters the hydrolysis fine desulfurization reactor 3 and the hydrolysis fine desulfurization reactor 4. There are two hydrolysis fine desulfurization reactors, One open and one standby, use in series. The hydrolysis fine desulfurization reactor can be filled with a volume of 9m 3 , the desulfurizer is filled in two layers, and the upper layer is filled with 2m 3 Hydrolysis Catalyst 5 and 4m 3 The fine desulfurizer 6 with iron oxide as the active component, the upper layer is hydrolyzed and finely desulfurized to reduce COS to 0.5ppm, and the lower layer is filled with 2m 3 Hydrolysis Ca...

Embodiment 2

[0024] The dry desulfurization purification process of ethylene-rich gas in a refinery in Shandong is shown in the attached figure 1 As shown, the content of ethylene-rich gas and main impurities is shown in Table 1. This comes from upstream 4000Nm 3 / h The ethylene-rich gas first passes through the coalescing filter 1 for rough dehydration, is heated to 120°C by the steam heater 2, and enters the hydrolysis fine desulfurization reactor 3 and the hydrolysis fine desulfurization reactor 4. There are two hydrolysis fine desulfurization reactors, One open and one standby, use in parallel. The hydrolysis fine desulfurization reactor can be filled with a volume of 9m 3 , the desulfurizer is filled in two layers, and the upper layer is filled with 2m 3 Hydrolysis Catalyst 5 and 4m 3 The fine desulfurizer 6 with iron oxide as the active component, the upper layer is hydrolyzed and finely desulfurized to reduce COS to 0.3ppm, and the lower layer is filled with 2m 3 Hydrolysis Cat...

Embodiment 3

[0026] The dry desulfurization purification process of ethylene-rich gas in a refinery in Shandong is shown in the attached figure 1 As shown, the content of ethylene-rich gas and main impurities is shown in Table 1. This comes from upstream 4000Nm 3 / h The ethylene-rich gas first passes through the coalescing filter 1 for rough dehydration, is heated to 100°C by the steam heater 2, and enters the hydrolysis fine desulfurization reactor 3 and the hydrolysis fine desulfurization reactor 4. There are two hydrolysis fine desulfurization reactors, One open one prepared, parallel connection. The hydrolysis fine desulfurization reactor can be filled with a volume of 9m 3 , the desulfurizer is filled in two layers, and the upper layer is filled with 2m 3 Hydrolysis Catalyst 5 and 4m 3 The fine desulfurizer 6 with iron oxide as the active component, the upper layer is hydrolyzed and finely desulfurized to reduce COS to 0.92ppm, and the lower layer is filled with 2m 3 Hydrolysis C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com