Water-based ultraviolet absorbing material and preparation method thereof

A technology for absorbing materials and ultraviolet rays, which is applied in the direction of radiation-absorbing coatings and coatings to achieve the effects of improving absorption capacity, large specific surface area, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

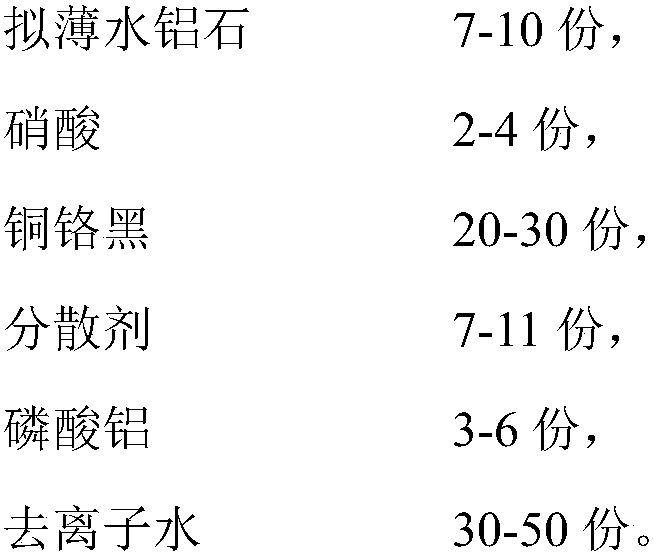

[0026] A water-based ultraviolet absorbing material is made of the following raw materials in parts by weight:

[0027]

[0028] Wherein, the mass fraction of nitric acid is 10%, and the particle diameter of copper chrome black is 40nm.

[0029] The preparation method of water-based ultraviolet absorbing material comprises the following steps:

[0030] 1) making nitric acid into an aqueous nitric acid solution with a mass fraction of 10%, and then mixing it with pseudo-boehmite for acidification for 1 hour to obtain acidified pseudo-boehmite;

[0031] 2) Mix the acidified pseudo-boehmite, copper chrome black and dispersant, and use a grinder to grind, and the grinding time is 4 hours, to obtain a mixed material with an average particle size of 2.5 μm;

[0032] 3) adding aluminum phosphate and water to the ground mixed material, and mixing evenly to obtain a water-based ultraviolet absorbing material.

[0033] The prepared water-based ultraviolet absorbing material is coat...

Embodiment 2

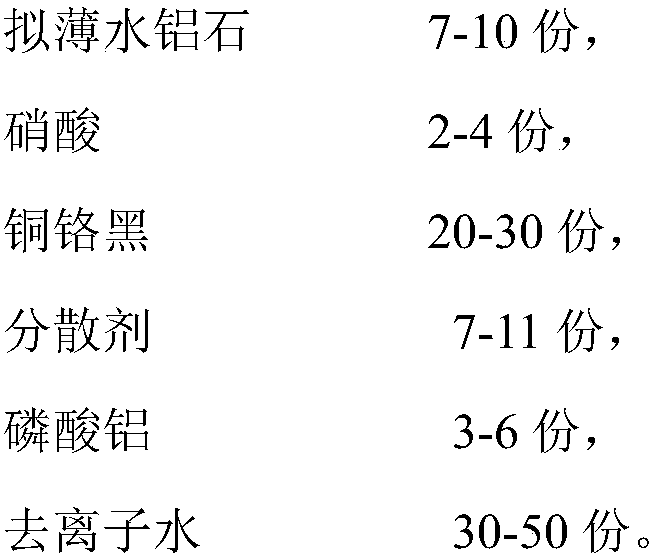

[0035] A water-based ultraviolet absorbing material is made of the following raw materials in parts by weight:

[0036]

[0037]

[0038] Wherein, the mass fraction of nitric acid is 15%, and the particle diameter of copper chrome black is 50nm.

[0039] The preparation method of water-based ultraviolet absorbing material comprises the following steps:

[0040] 1) Nitric acid is made into an aqueous solution of nitric acid with a mass fraction of 15%, and mixed with pseudo-boehmite for acidification for 0.5 h to obtain acidified pseudo-boehmite;

[0041] 2) Mix the acidified pseudo-boehmite, copper chrome black and dispersant, and grind with a grinder for 3.5 hours to obtain a mixed material with an average particle size of 3 μm;

[0042] 3) adding aluminum phosphate and water to the ground mixed material, and mixing evenly to obtain a water-based ultraviolet absorbing material.

[0043] The prepared water-based ultraviolet absorbing material is coated on the metal sur...

Embodiment 3

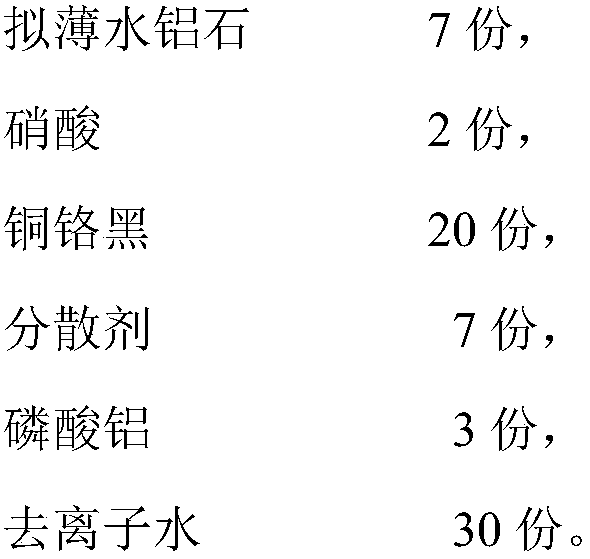

[0045] A water-based ultraviolet absorbing material is made of the following raw materials in parts by weight:

[0046]

[0047] Wherein, the mass fraction of nitric acid is 20%, and the particle diameter of copper chrome black is 60nm.

[0048] The preparation method of water-based ultraviolet absorbing material comprises the following steps:

[0049] 1) Nitric acid is made into an aqueous solution of nitric acid with a mass fraction of 20%, and mixed with pseudo-boehmite for acidification for 0.5 h to obtain acidified pseudo-boehmite;

[0050] 2) Mix the acidified pseudo-boehmite, copper chrome black and dispersant, and grind with a grinder for 3 hours to obtain a mixed material with an average particle size of 5 μm;

[0051] 3) adding aluminum phosphate and water to the ground mixed material, and mixing evenly to obtain a water-based ultraviolet absorbing material.

[0052] The prepared water-based ultraviolet absorbing material is coated on the metal surface that can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com