Crack-resistant paste for bituminous pavement layer

A technology of asphalt pavement and anti-crack paste, which is applied in the direction of roads, roads, pavement details, etc., can solve the problems of poor mechanical properties and heat resistance of anti-crack paste, achieve good thermal conductivity, enhance mechanical strength, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

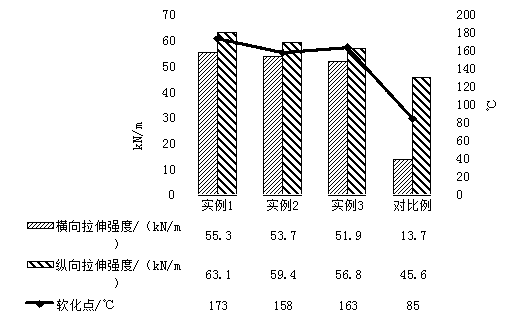

Examples

example 1

[0023] In terms of parts by weight, put 30 parts of phenolic resin and 6 parts of curing agent in No. 1 beaker, and stir and mix for 60 minutes under the condition of rotating speed of 600r / min to obtain the binder; the mass fraction is 80% of sulfuric acid and Nitric acid with a mass fraction of 30% was added to the No. 2 beaker at a mass ratio of 1:2, and stirred and mixed for 60 minutes at a speed of 600r / min to obtain a mixed acid; in parts by weight, 20 parts of carbon nanotube fibers, 30 Parts of ethyl orthosilicate and 30 parts of tetrabutyl titanate were placed in an ultrasonic disperser, and ultrasonically dispersed for 60 minutes at an ultrasonic frequency of 65kHz to obtain a primary dispersion, and then the resulting primary dispersion was filtered to obtain a primary treatment nano Carbon tube fiber: put the carbon nanotube fiber and water obtained in the primary treatment into an ultrasonic disperser at a mass ratio of 1:100, and ultrasonically disperse for 60 min...

example 2

[0025] In terms of parts by weight, put 30 parts of phenolic resin and 6 parts of curing agent in No. 1 beaker, and stir and mix for 60 minutes under the condition of rotating speed of 600r / min to obtain the binder; the mass fraction is 80% of sulfuric acid and Nitric acid with a mass fraction of 30% was added to the No. 2 beaker at a mass ratio of 1:2, and stirred and mixed for 60 minutes at a speed of 600r / min to obtain a mixed acid; in parts by weight, 20 parts of carbon nanotube fibers, 30 Parts of tetrabutyl titanate were placed in an ultrasonic disperser, and ultrasonically dispersed for 60 minutes at an ultrasonic frequency of 65 kHz to obtain a primary dispersion, and then the resulting primary dispersion was filtered to obtain primary carbon nanotube fibers; the resulting primary treatment Carbon nanotube fibers and water are placed in an ultrasonic disperser at a mass ratio of 1:100, and ultrasonically dispersed for 60 minutes at an ultrasonic frequency of 65 kHz to o...

example 3

[0027]In terms of parts by weight, put 30 parts of phenolic resin and 6 parts of curing agent in No. 1 beaker, and stir and mix for 60 minutes under the condition of rotating speed of 600r / min to obtain the binder; the mass fraction is 80% of sulfuric acid and Nitric acid with a mass fraction of 30% was added to the No. 2 beaker at a mass ratio of 1:2, and stirred and mixed for 60 minutes at a speed of 600r / min to obtain a mixed acid; in parts by weight, 20 parts of carbon nanotube fibers, 30 Parts of tetraethyl orthosilicate were placed in an ultrasonic disperser, and ultrasonically dispersed for 60 minutes at an ultrasonic frequency of 65 kHz to obtain a primary dispersion, and then the resulting primary dispersion was filtered to obtain primary carbon nanotube fibers; the resulting primary treatment Carbon nanotube fibers and water are placed in an ultrasonic disperser at a mass ratio of 1:100, and ultrasonically dispersed for 60 minutes at an ultrasonic frequency of 65 kHz ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com