Rare-earth-based flexible nuclear radiation protection material, and preparation method and application thereof

A protective material and base flexible technology, applied in the field of nuclear radiation protection, can solve the problems of secondary pollution of heavy metals such as pipelines, equipment, lead, etc., inconvenient operation and maintenance, etc., and achieve good radiation protection effect and compactness Good effect with high processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

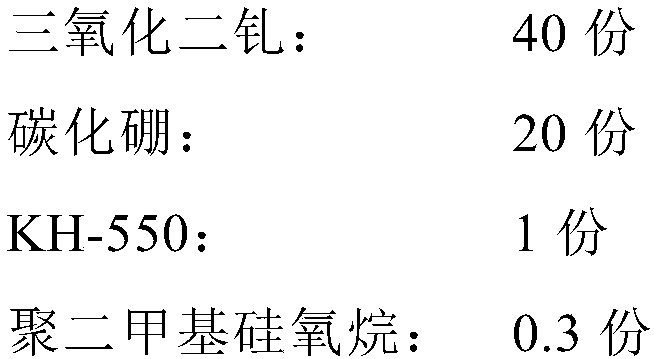

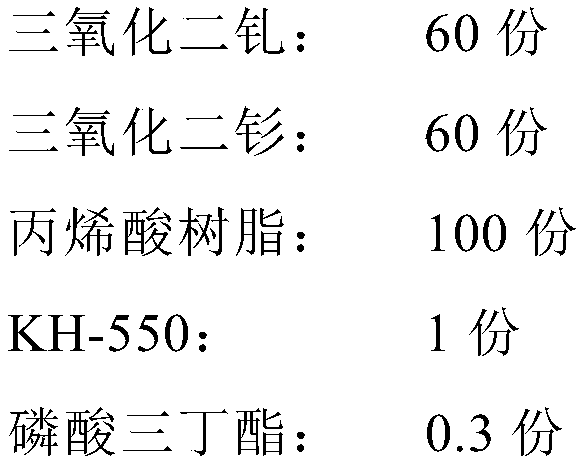

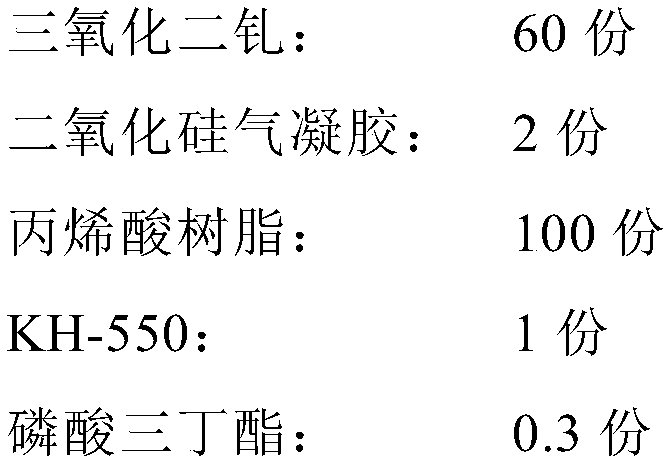

[0026] A material with neutron shielding effect, consisting of the following components in parts by weight:

[0027] Gadolinium trioxide: 60 parts

[0028] KH-550: 1 serving

[0029] Polydimethylsiloxane: 0.3 parts

[0030] KH-550 is used as a coupling agent, and polydimethylsiloxane is used as a defoamer.

[0031] The preparation method proceeds as follows:

[0032] (1) Weigh a sufficient amount of Gd with a particle size of 200-400 mesh 2 o 3 The powder was dried in an oven at 80°C for 12 hours to obtain a dry powder, and 60 parts of Gd 2 o 3 Powder;

[0033] (2) Mix the powder obtained in step (1) with 1 part of KH-550 and 0.3 part of polydimethylsiloxane, and stir at a speed of 1500 rpm for 2 hours until fully mixed to obtain a surface-treated The core radiation protection material (Ⅰ);

[0034] (3) Weigh 100 parts of water-based acrylic resin, add the material (I) obtained in step (2) into it, and mechanically stir it at a speed of 1500 rpm for 10 minutes to full...

Embodiment 2

[0037] The difference between this example and Example 1 is that the material (I) and acrylic resin are mixed uniformly to obtain a slurry, which is uniformly coated on the base cloth, and then a layer of PE film is adhered to the surface, and then heated at 50°C Drying under air blast for 4 hours, a raw material (Ⅲ) of a rare earth-based flexible nuclear radiation protection wrapping tape with a sandwich structure was obtained.

Embodiment 3

[0039] The difference between this example and Example 1 is that after obtaining material (I), weigh 100 parts of methyl silicone rubber (raw rubber) or polyimide masterbatch, mix and extrude at 150°C , forming, to produce rubber and plastic products (Ⅳ) that meet different needs and have radiation protection and temperature resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com