Quantum dot light emitting diode and preparation method thereof

A quantum dot light-emitting and diode technology, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electric solid-state devices, etc., can solve the problem of unbalanced carrier migration efficiency, so as to solve the problem of unbalanced carrier migration efficiency and improve the The effect of current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

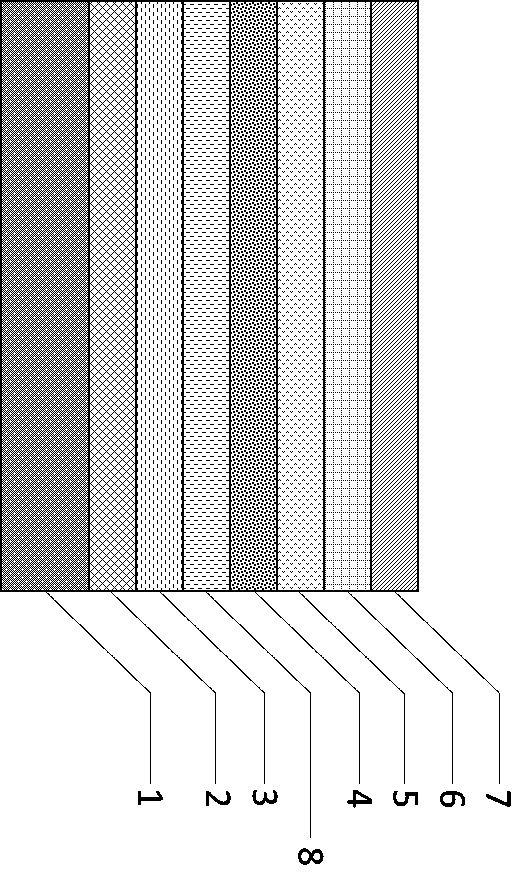

[0022] Embodiment one: if figure 1 As shown, a quantum dot light-emitting diode includes a glass substrate, a first conductive layer, an electron injection layer, a quantum dot light-emitting layer, a hole transport layer, a hole injection layer and a second layer that are sequentially stacked on the glass substrate. Conductive layer, an electron transport passivation layer is also arranged between the quantum dot luminescent layer and the electron injection layer, and the glass substrate can also be a glass substrate that has been prepared for LTPS devices.

[0023] In this embodiment, the first conductive layer is one of ITO, FTO or AZO.

[0024] The electron injection layer is one of zinc oxide, gallium oxide or nickel oxide, and its material structure is one or more combinations of nano film, nano particle, nano wire, nano sheet or nano belt.

[0025] The electron transport passivation layer is one or more combinations of zirconium oxide, hafnium oxide, silicon oxide, alu...

Embodiment 2

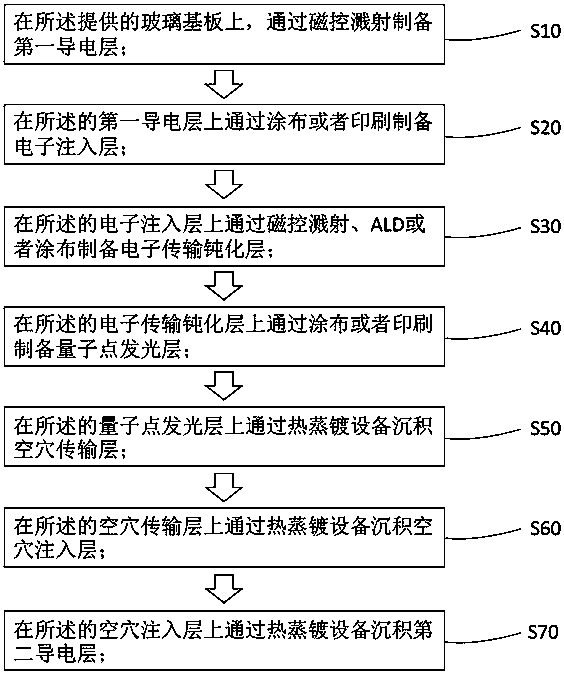

[0030] Embodiment two: if figure 2 As shown, a method for preparing a quantum dot light-emitting diode includes the following steps: S10, preparing a first conductive layer with a thickness of 5-200 nm on a glass substrate by magnetron sputtering; S20, passing Coating or printing to prepare an electron injection layer with a thickness of 10-300nm; S30, forming an electron transport passivation layer on the electron injection layer; S40, preparing a thickness of 5-200nm quantum dot light-emitting layer; S50, depositing a hole transport layer with a thickness of 5-200nm on the quantum dot light-emitting layer by thermal evaporation equipment; S60, depositing a hole transport layer on the hole transport layer by thermal evaporation The equipment deposits a hole injection layer with a thickness of 5-200 nm; S70, depositing a second conductive layer with a thickness of 5-200 nm on the hole injection layer by thermal evaporation equipment.

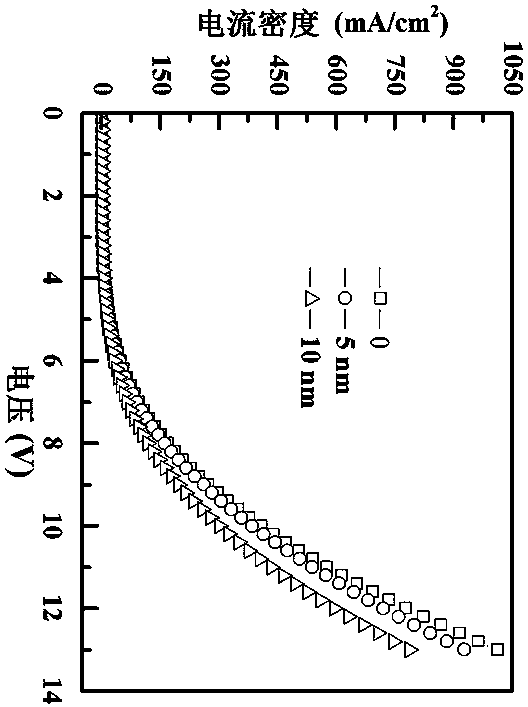

[0031] Wherein, in the step S30, the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com