Fabrication method of soft package lithium-sulfur battery

A lithium-sulfur battery and a manufacturing method technology are applied in the direction of lithium-sulfur battery, electrolyte battery manufacturing, battery electrodes, etc., which can solve the problem of low specific capacity of lithium-sulfur battery at first discharge, increase migration and diffusion resistance, improve utilization rate, The effect of increasing the overall capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

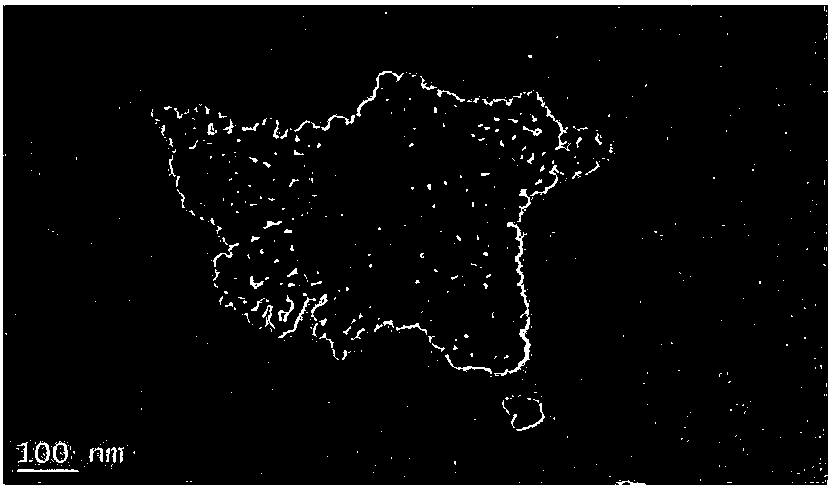

[0052] Ball mill 2g of porous carbon and 1g of sublimated sulfur for 10 hours to obtain a solid mixed powder; put the solid mixed powder into a hydrothermal reaction kettle, place it in a vacuum oven, and keep it warm at 170°C for 5 hours. After the reaction is completed, about 3g of sulfur / porous carbon is obtained Composite materials; the sulfur / porous carbon hybrid material was placed in a ball mill jar, and Co 3 o 4 After ball milling for 300min, Co 3 o 4 - Sulfur / porous carbon composites, where Co 3 o 4 The addition amount is 2wt% of the composite material; the Co 3 o 4 - Sulfur / porous carbon composites by Co 3 o 4 - Sulfur / porous carbon composite material: Super P: PVDF=95:2:3 (mass ratio) mixed with an appropriate amount of NMP, stirred at room temperature for 12 hours, so that the slurry was evenly mixed, and the solid content of the obtained slurry was 40%; then Use a coating machine to evenly coat the slurry on the aluminum foil, then place the aluminum foil ...

Embodiment 2

[0054] Ball mill 6g of KS-6 and 1g of sublimed sulfur for 5.5h to obtain a solid mixed powder; put the solid mixed powder into a hydrothermal reaction kettle, place it in a vacuum oven, and keep it warm at 145°C for 12.5h. After the reaction, about 7g of sulfur / KS-6 composite material; place the sulfur / KS-6 composite material in a ball mill jar, add Mg 0.6 Ni 0.4 After O, ball milled for 165min to obtain Mg 0.6 Ni 0.4 O-sulfur / KS-6 composite material, where Mg 0.6 Ni 0.4 The addition of O is 15wt% of the composite material; the Mg 0.6 Ni 0.4 O-sulfur / KS-6 composite material by Mg 0.6 Ni 0.4 O-sulfur / KS-6 composite material: (Super P+ graphene): (PVDF+PTFE) = 75:18:7 (mass ratio) mixed with an appropriate amount of NMP and deionized water, stirred at room temperature for 12 hours, and made the slurry Mix evenly, the solid content of the obtained slurry is 55%; then use a coating machine to evenly coat the slurry on the aluminum foil, then put the aluminum foil coated w...

Embodiment 3

[0056] Ball mill 10g of graphene-porous carbon and 1g of sublimated sulfur for 1 hour to obtain a solid mixed powder; put the solid mixed powder into a hydrothermal reaction kettle, place it in a vacuum oven, and keep it warm at 120°C for 20 hours. After the reaction, about 11g of sulfur / Graphene-porous carbon composite material; place the sulfur / graphene-porous carbon hybrid material in a ball mill jar, then add Mg 0.6 Ni 0.4 O and Co 3 o 4 After ball milling for 30min, Mg 0.6 Ni 0.4 O-Co 3 o 4 - Sulfur / graphene-porous carbon composites, where Mg 0.6 Ni 0.4 O and Co 3 o 4 The total amount added is 30wt% of the composite material; the Mg 0.6 Ni 0.4 O-Co 3 o 4 - Sulfur / graphene-porous carbon composites by Mg 0.6 Ni 0.4 O-Co 3 o 4 - Sulfur / graphene-porous carbon composite material: (KS-6+ carbon nanotube): (PVDF+SBR) = 55:35:10 (mass ratio) mixed with an appropriate amount of NMP, stirred at room temperature for 12 hours, to make the slurry Mix evenly, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com