Modifying method for sandy soil

A soil and soil pit technology, applied in the agricultural field, can solve problems such as difficult growth and environmental degradation, and achieve the effects of improving water retention performance, improving soil environment, and improving desertification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

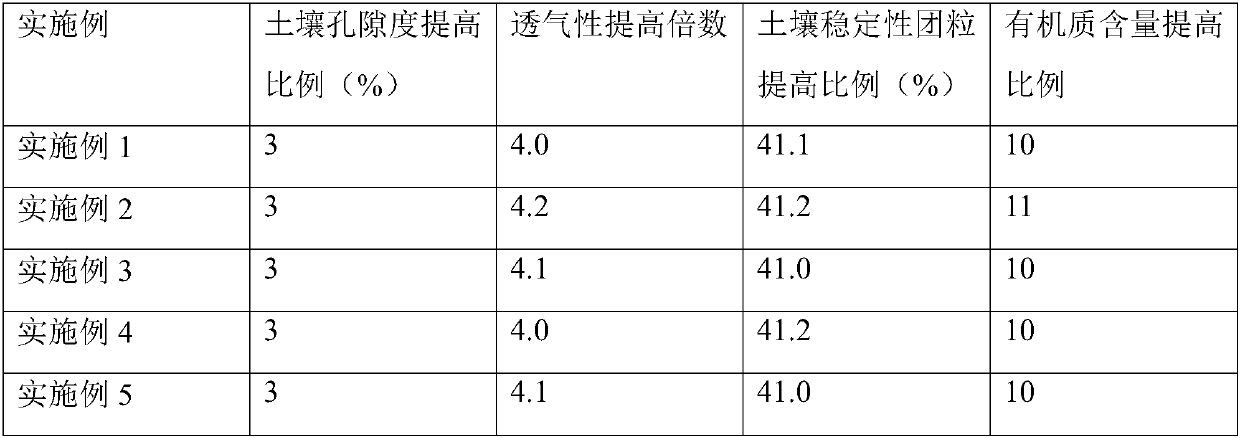

Examples

Embodiment 1

[0024] Step (1) plowing the desertified soil, the plowing depth is 30cm, and the plowed soil is put aside earlier to form an earth pit;

[0025] Step (2) Laying a layer of straw layer in the pit, the thickness of the straw layer is 3cm, spraying water on the straw layer until the straw layer is completely soaked; evenly sprinkle the microbial agent on the straw layer , the microbial agent includes one or more of Bacillus subtilis, lactic acid bacteria and yeast; the microbial agent includes Bacillus subtilis, lactic acid bacteria and yeast, and the mass ratio of Bacillus subtilis, lactic acid bacteria and yeast is 2:2:5;

[0026] Step (3) laying fermented layer on described microbial bacterial agent, the thickness of described fermented layer is 2cm, described fermented layer comprises bean dregs, distiller's grains and water mix, and the mass ratio of described bean dregs, described distiller's grains and water is 1:1:10, the mass ratio of the fermented layer to the microbia...

Embodiment 2

[0031] Step (1) plowing the sandy soil, the plowing depth is 40cm, the plowed soil is put aside earlier to form an earth pit;

[0032] Step (2) Laying a layer of straw layer in the pit, the thickness of the straw layer is 7cm, spraying water on the straw layer until the straw layer is completely soaked; evenly sprinkle the microbial agent on the straw layer , the microbial agent includes one or more of Bacillus subtilis, lactic acid bacteria and yeast;

[0033]Step (3) laying fermented layer on described microbial bacterial agent, the thickness of described fermented layer is 2cm, described fermented layer comprises bean dregs, distiller's grains and water mix, and the mass ratio of described bean dregs, described distiller's grains and water is 1:1:15, the mass ratio of the fermented layer to the microbial inoculant is 25:1;

[0034] Step (4) laying a leaf layer on the fermentation layer, the thickness of the leaf layer is 3cm, and spraying water to the leaf layer until all ...

Embodiment 3

[0038] Step (1) plowing the sandy soil, the plowing depth is 33cm, the plowed soil is put aside earlier to form an earth pit;

[0039] Step (2) Laying a layer of straw layer in the pit, the thickness of the straw layer is 3cm, spraying water on the straw layer until the straw layer is completely soaked; evenly sprinkle the microbial agent on the straw layer , the microbial agent includes one or more of Bacillus subtilis, lactic acid bacteria and yeast;

[0040] Step (3) laying fermented layer on described microbial bacterial agent, the thickness of described fermented layer is 1cm, and described fermented layer comprises bean dregs, distiller's grains and water mixing, and the mass ratio of described bean dregs, described distiller's grains and water is 1:1:10, the mass ratio of the fermented layer to the microbial inoculant is 20:1;

[0041] Step (4) laying a leaf layer on the fermentation layer, the thickness of the leaf layer is 2cm, and then spraying water to the leaf lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com