Semipermeable-membrane supporting material and preparation method thereof

A support material and semi-permeable membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

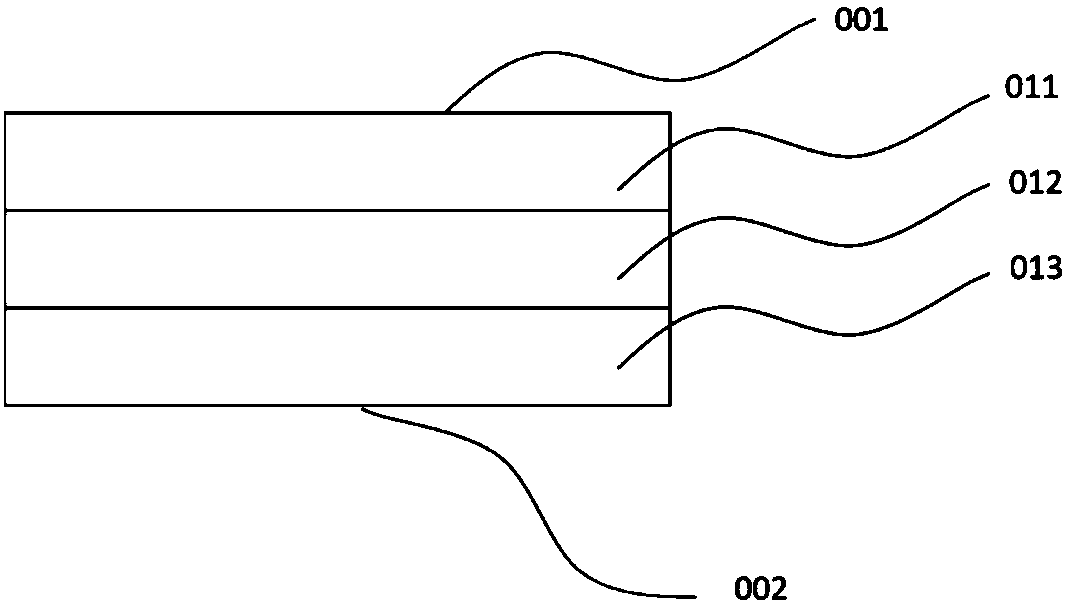

[0030] A preparation method for a semipermeable membrane support material, the method comprising the steps of:

[0031] Step 1: Add fiber raw materials to water to prepare a variety of fiber dispersions with an initial concentration of 0.1wt%-3.0wt%. The fibers include main fibers and binder fibers, and the main body in each fiber dispersion At least one of the fiber content or fiber parameters of the fiber and the binder is different, and the average diameter of the main fibers in the fiber dispersion with a high concentration is not larger than that in the fiber dispersion with a low concentration;

[0032] Step 2: Then adopt a 2-4 stage dispersion process, that is, disperse the various fiber dispersions prepared in step 1 respectively, and then dilute them. After multiple dispersions and dilutions, various online concentrations of 0.05wt%-0.001 wt% of the fiber dispersion, the multi-stage dispersion process, each dilution and dispersion is counted as one level;

[0033] St...

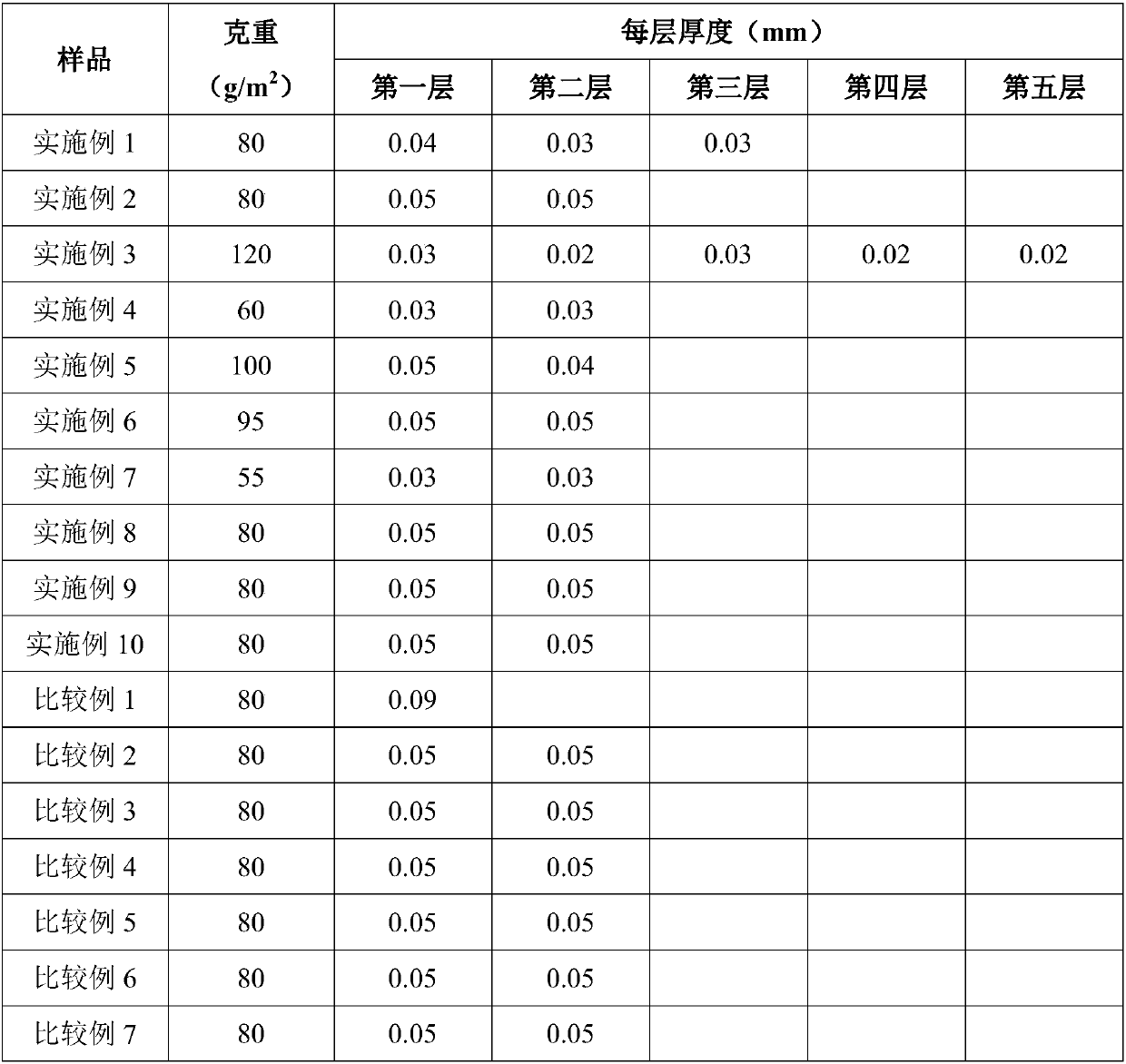

Embodiment 1

[0048] Step 1: Add the main fiber and binder fiber raw materials into water to prepare three kinds of fiber dispersions. The parameters of each fiber dispersion are as follows:

[0049] The first type, in the dispersion, main fiber, 65wt%, PET, melting point 255°C, diameter 7μm, length 6mm; binder fiber, 35wt%, single-component incompletely stretched / oriented polyester fiber, melting point 210°C , 7 μm in diameter, 6 mm in length; the initial dispersion concentration of the fiber is 0.1%, and the online concentration is 0.01wt%;

[0050] The second type, main fiber, 70wt%, PET, melting point 255°C, diameter 7μm, length 6mm; binder fiber, 30wt%, single-component incompletely stretched / oriented polyester fiber, melting point 210°C, diameter 7μm, The length is 6mm; the initial dispersion concentration of the total fiber is 0.1%, and the online concentration is 0.008wt%;

[0051] The third type, main fiber, 70wt%, PET, melting point 255°C, diameter 7μm, length 6mm; binder fiber, ...

Embodiment 2

[0056] Step 1: Add the main fiber and binder fiber raw materials into water to prepare two kinds of fiber dispersions. The parameters of each dispersion are as follows:

[0057] The first type, main fiber, 70wt%, PET, melting point 255°C, diameter 7μm, length 6mm; binder fiber, 30wt%, single-component incompletely stretched / oriented polyester fiber, melting point 210°C, diameter 7μm, The length is 6mm; the initial dispersion concentration of the total fibers is 0.1%, and the concentration on the net is 0.01wt%.

[0058] The second type, main fiber, 70wt%, PET, melting point 255°C, diameter 7μm, length 6mm; binder fiber, 30wt%, single-component incompletely stretched / oriented polyester fiber, melting point 210°C, diameter 7μm, The length is 6mm; the initial dispersion concentration of the total fibers is 0.1%, and the concentration on the Internet is 0.008wt%.

[0059] Step 2: Adopt a two-stage dispersion process, that is, disperse the two kinds of fiber dispersions prepared i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com