Fatty acid decarboxylation method

A fatty acid and decarboxylation technology, applied in chemical instruments and methods, hydrocarbons, metal/metal oxide/metal hydroxide catalysts, etc. low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of nano zirconia provided by the invention, the specific steps are as follows:

[0028] a) dissolving the zirconium salt in water to form a solution, preferably at least one of zirconium nitrate, zirconyl nitrate, zirconium oxychloride and zirconium chloride;

[0029] b) adding alkali solution under stirring until the specified pH value is reached, and the pH value at the end point is in the range of 7-12;

[0030] c) Adjust the ambient temperature to 0-150°C, add a reflux device to reflux the precipitate in the alkaline solution for 1-60 hours, and keep the pH value of the mother liquor constant during the entire reflux process;

[0031] d) Filtrating and washing the precipitate until free of impurity ions, drying and roasting. The drying temperature is 60-150°C, the drying time is 4-48 hours, the roasting temperature is 200-800°C, and the roasting time is 1-12 hours.

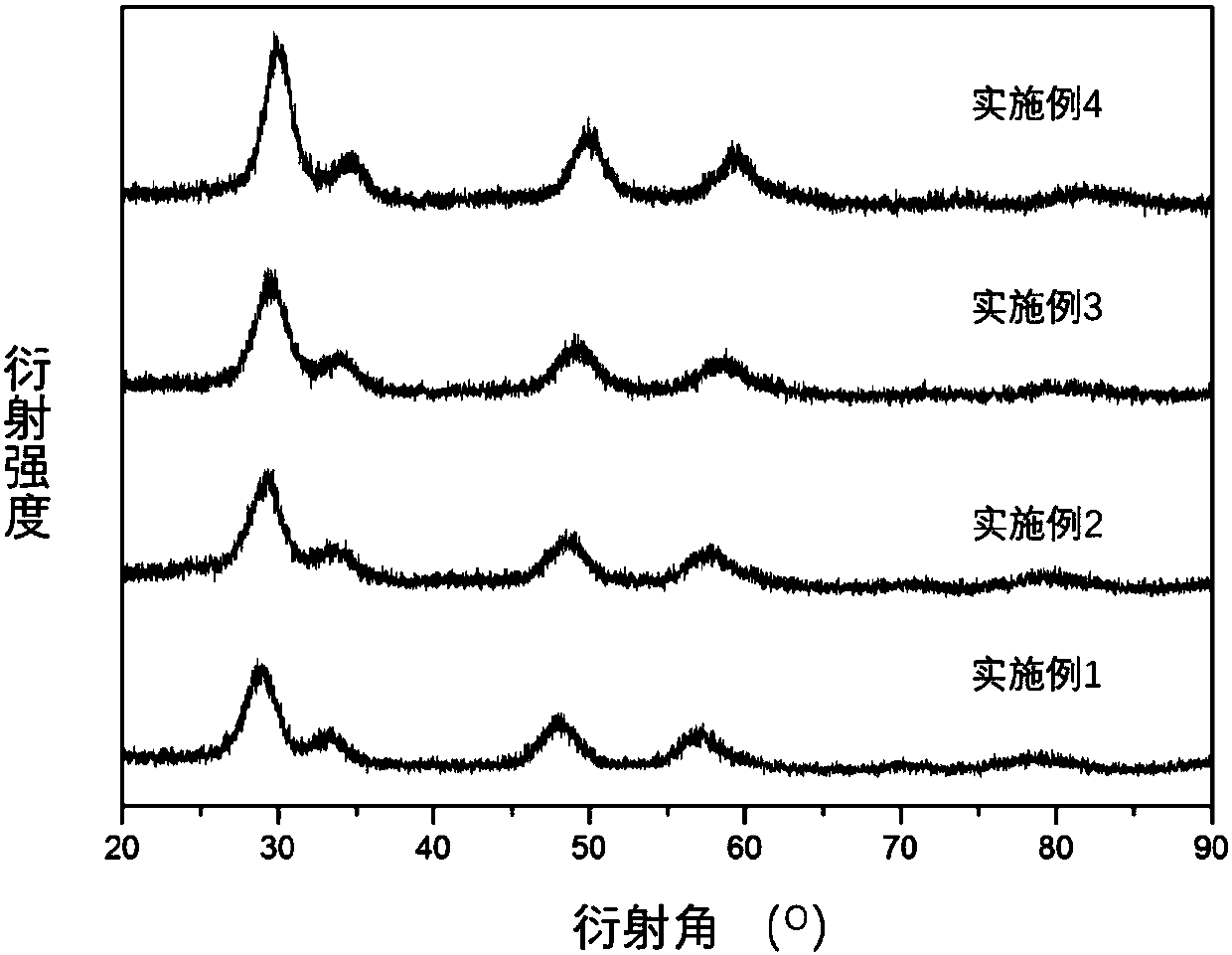

Embodiment 1~4

[0034] Dissolve zirconium nitrate, zirconium oxychloride, oxynitrate and zirconium chloride in deionized water to make 0.5mol L -1 solution, turn on the stirring, add concentrated ammonia water (mass fraction 37%) dropwise at a stirring speed of 300rpm to pH=9, add a reflux device, raise the solution temperature to 100°C, and reflux for 48 hours. Filter and wash the precipitate until there are no impurity ions, dry at 120°C, and bake at 500°C for 4 hours to obtain nano-zirconia. Its structural characterization is shown in Table 1.

Embodiment 5~6

[0036] Dissolve zirconium oxychloride in deionized water to make 0.5mol L -1 solution, turn on the stirring, and add NaOH (2mol L) dropwise at a stirring speed of 300rpm -1 ) and KOH (2mol L -1 ) solution to pH=9, add a reflux device, increase the solution temperature to 100°C, and reflux for 48 hours. Filter and wash the precipitate until there are no impurity ions, dry at 120°C, and bake at 500°C for 4 hours to obtain nano-zirconia. Its structural characterization is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com