Milk powder drunk by premature infant and preparation method of milk powder

A technology of premature infants and milk powder, which is applied in the field of premature infants drinking milk powder and its preparation, can solve the problems of immature intestinal digestive system, low utilization rate of digestion and absorption, and achieve the effect of enhancing immunity and promoting intestinal peristalsis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

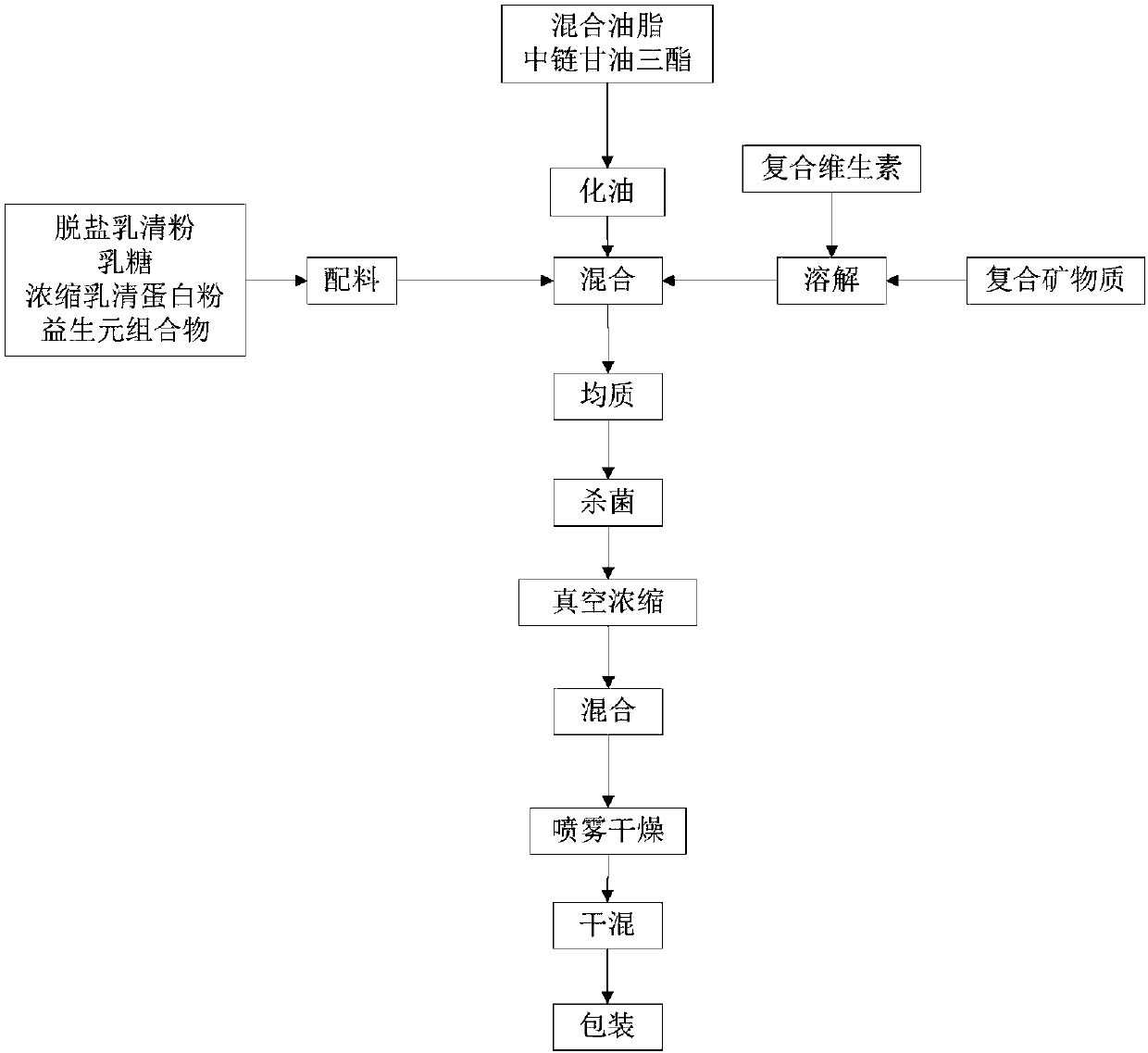

Method used

Image

Examples

Embodiment 1

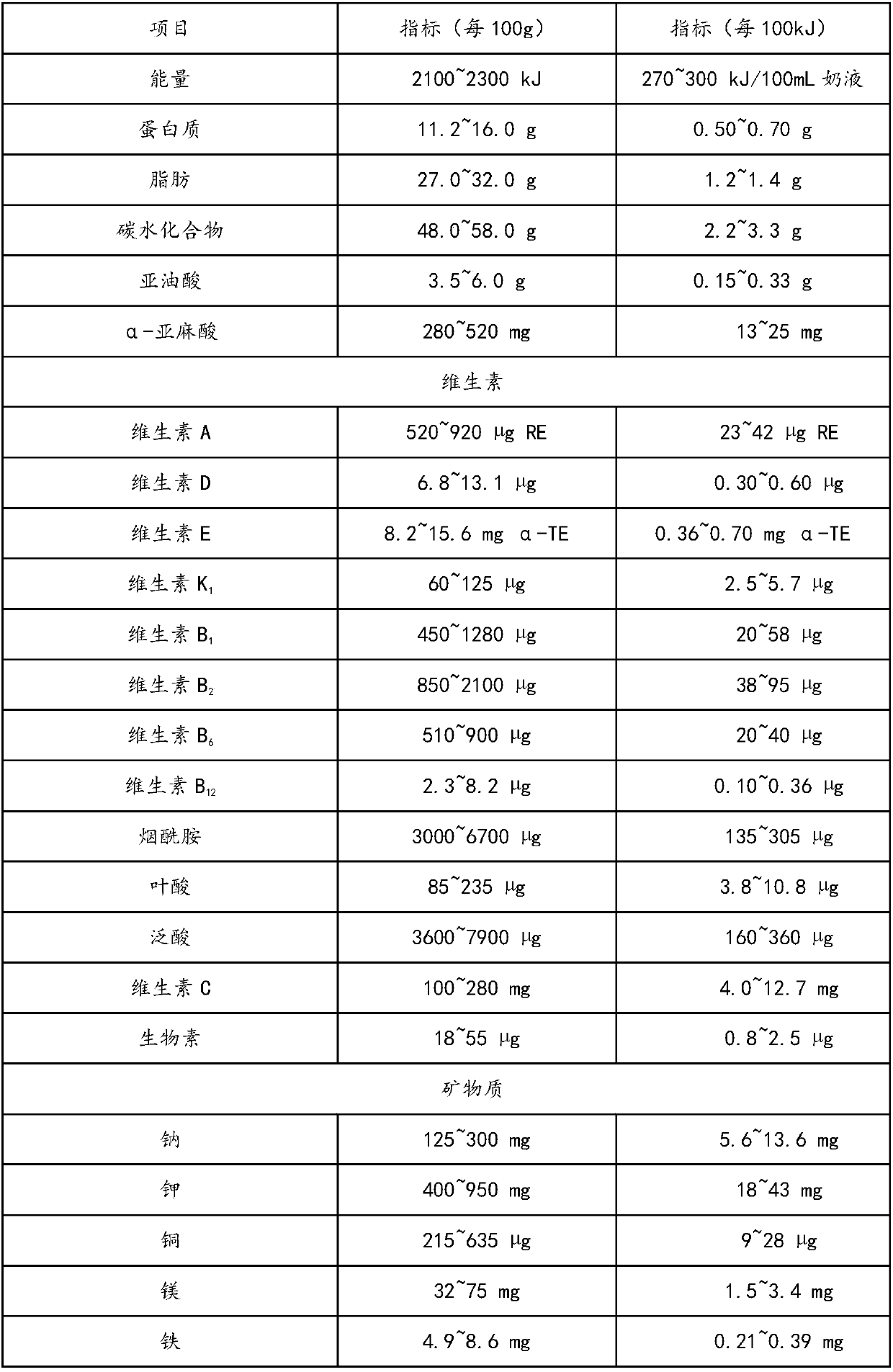

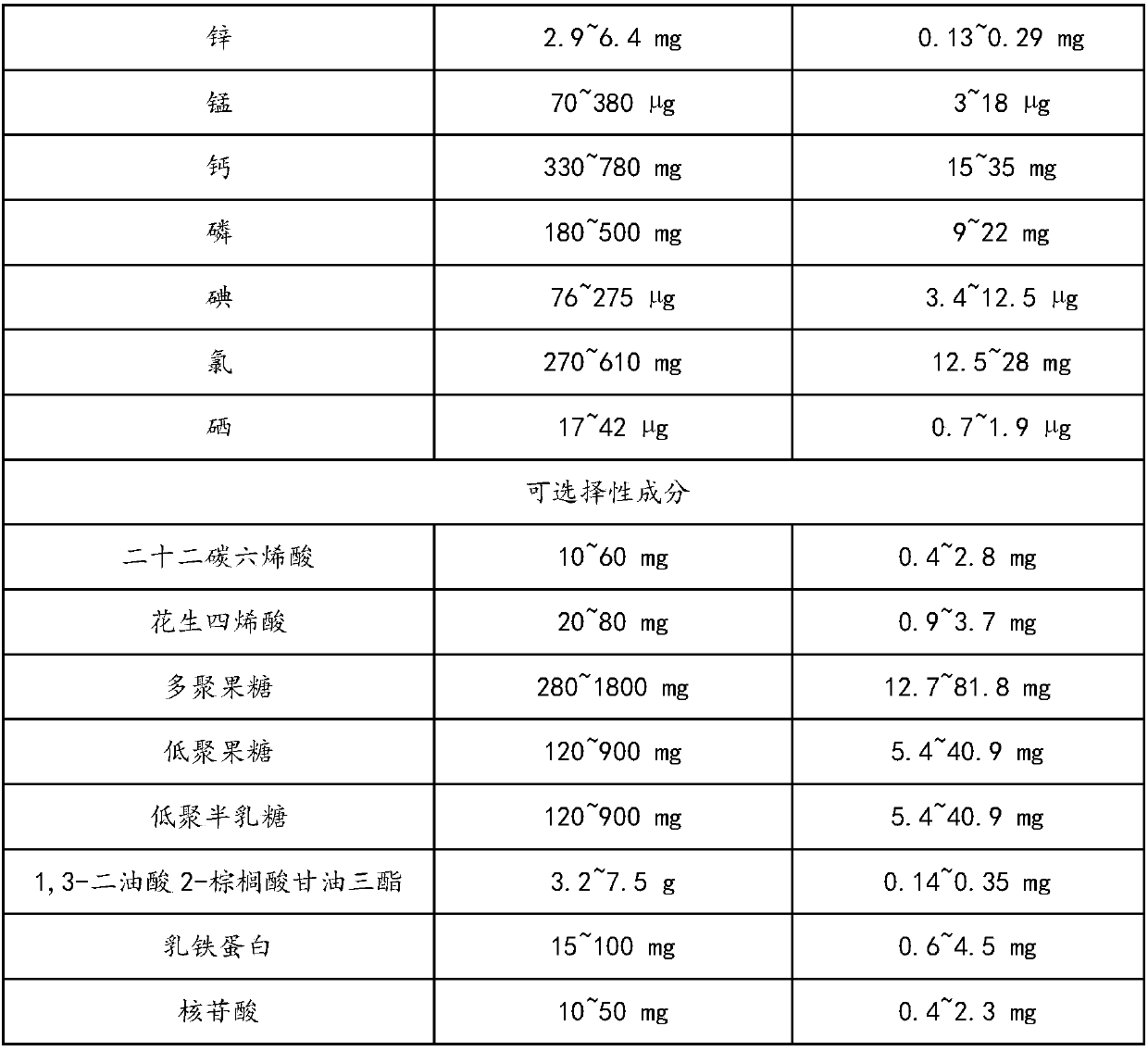

[0081] The raw material formula of table 2 embodiment 1

[0082]

[0083] The specific manufacturing method is as follows:

[0084] (1) Ingredients: Mix desalted whey powder, lactose, concentrated whey protein powder, prebiotic composition and water according to the above-mentioned proportions until they are completely dissolved. The mixing temperature is 40°C and the mixing time is 15 minutes. , to obtain the feed liquid A, the feeding order is not in any order when the materials are mixed.

[0085] (2) Carburetion: Preheat the mixed oil and medium-chain triglyceride to 50°C, and then mix for 10 minutes to obtain material liquid B.

[0086] (3) Mixing: Mix the feed liquid B and the feed liquid A for 10 minutes, and then carry out secondary homogenization, wherein the pressure of the primary homogeneity is 18MPa, and the pressure of the secondary homogeneity is 3MPa. The temperature was 55°C, and the feed liquid C was obtained.

[0087] (4) Vitamin dissolution: Dissolve ...

Embodiment 2

[0096] The raw material formula of table 4 embodiment 2

[0097]

[0098] The specific manufacturing method is as follows:

[0099] (1) Ingredients: Mix desalted whey powder, lactose, concentrated whey protein powder, prebiotic composition and water according to the above-mentioned proportions until they are completely dissolved. The mixing temperature is 45°C and the mixing time is 20 minutes. , to obtain the feed liquid A, the feeding order is not in any order when the materials are mixed.

[0100] (2) Carburetion: preheat the mixed oil and medium-chain triglyceride to 55°C, and then mix for 20 minutes to obtain material liquid B.

[0101] (3) Mixing: Mix the feed liquid B and the feed liquid A for 20 minutes, and then carry out secondary homogenization, wherein the pressure of the primary homogeneity is 20MPa, and the pressure of the secondary homogeneity is 5MPa. The temperature is 60°C, and the feed liquid C is obtained.

[0102] (4) Vitamin dissolution: Dissolve mu...

Embodiment 3

[0111] The raw material formula of table 6 embodiment 3

[0112]

[0113] The specific manufacturing method is as follows:

[0114] (1) Ingredients: Mix desalted whey powder, lactose, concentrated whey protein powder, prebiotic composition and water according to the above-mentioned proportions until they are completely dissolved. The mixing temperature is 42°C and the mixing time is 18 minutes. , to obtain the feed liquid A, the feeding order is not in any order when the materials are mixed.

[0115] (2) Carburetion: Preheat the mixed oil and medium-chain triglyceride to 53°C, and then mix for 15 minutes to obtain material liquid B.

[0116] (3) Mixing: Mix the feed liquid B and the feed liquid A for 18 minutes, and then perform secondary homogenization, wherein the pressure of the primary homogeneity is 19MPa, and the pressure of the secondary homogeneity is 4MPa. The temperature was 57°C, and the feed liquid C was obtained.

[0117] (4) Vitamin dissolution: Dissolve mu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap