Modified gelatin based composite sponge and preparation method and application thereof

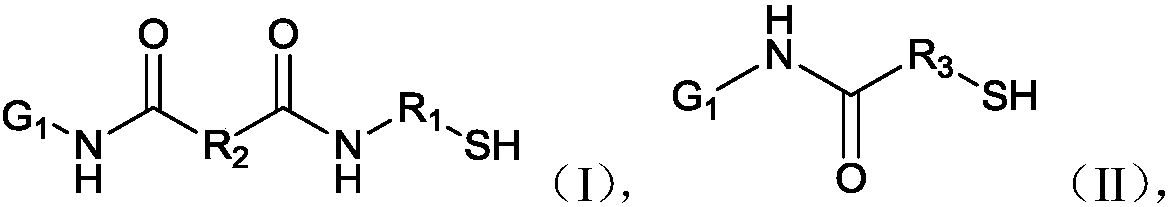

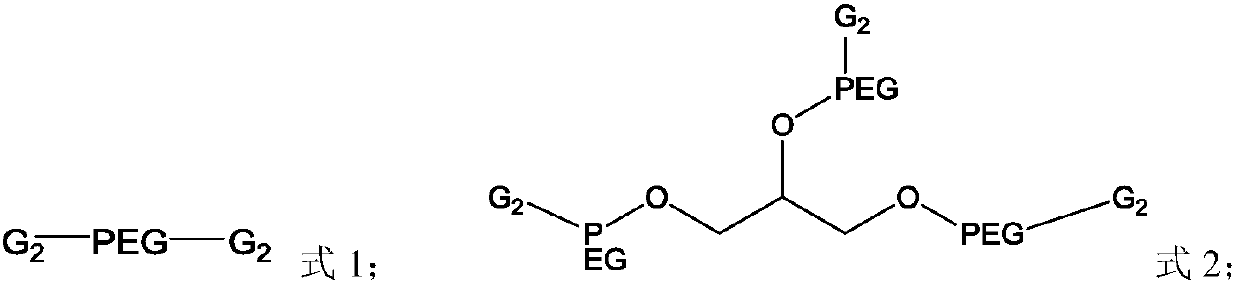

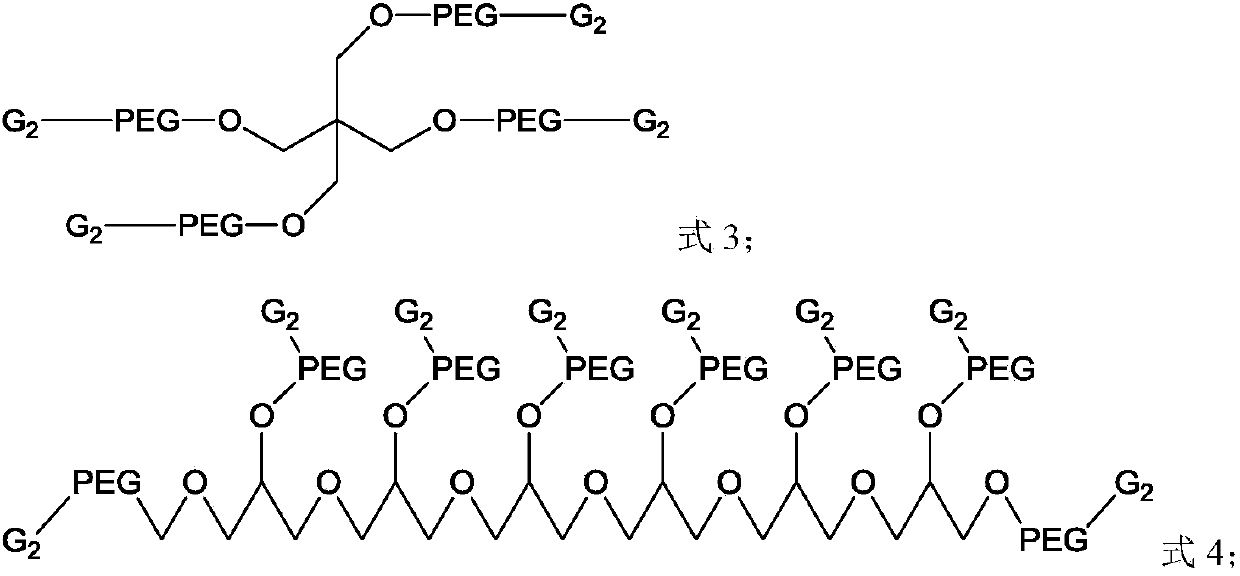

A composite sponge and gelatin technology, which is applied in the field of composite sponge materials and its preparation, can solve the problems of gelatin sponge with single components, single ingredients, and inflammatory reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Example 1 Preparation of thiol-modified gelatin synthesized by modification of bisuccinic acid bisacylcystine dicarbonyldiimidazole activated ester

[0066] Dissolve 10 g of cystamine dihydrochloride in 150 ml of distilled water, and magnetically stir the transparent solution. Add 4 mol / L sodium hydroxide to the above solution to adjust the pH of the solution to 9-10. Then add 13.3g of succinic anhydride, and continuously add 4mol / L of sodium hydroxide to keep the pH value of the solution at 8-10. 3. The white precipitated product was collected by filtration, and the filter cake was washed 3 times with 200ml of distilled water. Then it was placed in a blast oven at 50°C and dried to obtain about 13.4 g of white solid bisuccinic acid bisacylcystine.

[0067] Add 10g of bisuccinic acid bisylcystine and 60ml of anhydrous N'N-dimethylformamide into a 250mL beaker. After magnetically stirring at room temperature to dissolve, add 11.2g of carbonyldiimidazole. After about 2 ...

Embodiment 2

[0072] Example 2 Preparation of Modified Gelatin-Based Composite Sponge

[0073] Add 2.4 g of mercapto-modified gelatin (type A, from pigskin, Rossano, China) synthesized by modifying bisuccinic acid bisacylcystine dicarbonyldiimidazole activated ester into a 100 ml beaker, and mix with 40 ml pH The phosphate buffer solution of =7.4 dissolves, after dissolving, add 0.12g of hyaluronic acid and continue to stir to make it dissolve. Use a mechanical stirrer to stir for 5 minutes at a speed of 1600 rpm. At this time, a stable foam with a volume 5-6 times the volume of the original mixed solution is formed, and then add 2.5ml of double-armed polyethylene glycol acrylic acid with a concentration of 2.4%. Ester (2-arm-PEGDA) test solution, continue to stir for 1 minute, transfer the foam to a metal mold and place the mold in a 30°C oven for 5 minutes to complete the crosslinking of the foam. In order to make the foam continue to harden, the mold was transferred to a refrigerator at...

Embodiment 3

[0074] Embodiment 3 prepares modified gelatin-based composite sponge

[0075] Add 2.4 g of mercapto-modified gelatin (type A, from pigskin, Rossano, China) synthesized by modifying bisuccinic acid bisacylcystine dicarbonyldiimidazole activated ester into a 100 ml beaker, and mix with 40 ml pH The phosphate buffer solution of =7.4 dissolves, and after dissolving, add 0.06g of hyaluronic acid and continue to stir to make it dissolve. Use a mechanical stirrer to stir for 5 minutes at a speed of 1600 rpm. At this time, a stable foam with a volume 5-6 times the volume of the original mixed solution is formed, and then add 2.5ml of double-armed polyethylene glycol acrylic acid with a concentration of 2.4%. Ester (2-arm-PEGDA) test solution, continue to stir for 1 minute, transfer the foam to a metal mold and place the mold in a 30°C oven for 5 minutes to complete the crosslinking of the foam. In order to make the foam continue to harden, the mold was transferred to a refrigerator a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com