Gypsum-based putty

A gypsum-based, putty technology, applied in filling slurry and other directions, can solve the problems of poor water resistance, powder falling, peeling and peeling, rust, etc., to improve mechanical properties and water resistance, excellent adhesion, and a wide range of sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

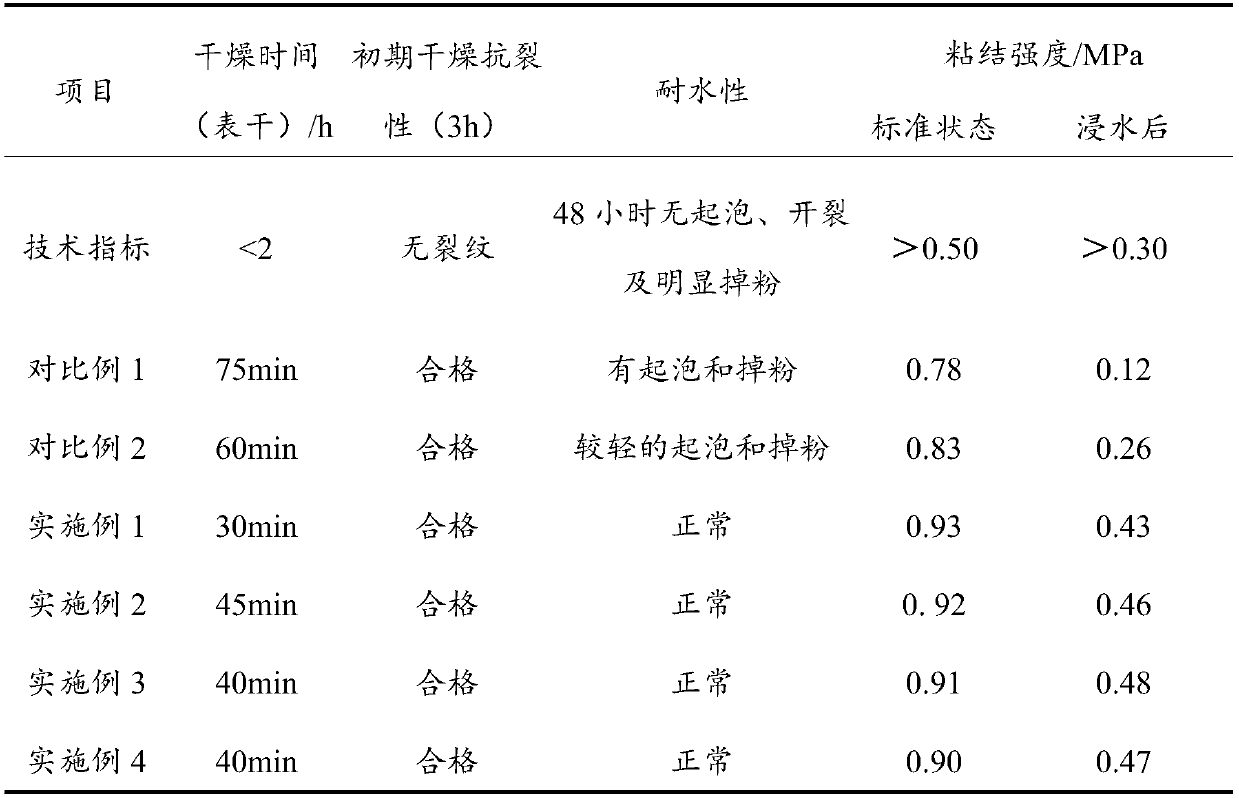

Examples

Embodiment 1

[0029] A kind of gypsum-based putty, comprising the following components by mass: 40 parts of β-type hemihydrate gypsum, gray calcium (the number of mesh is 400 mesh, Ca(OH) 2 Content ≥ 90%) 3 parts, silica fume (specific surface area ≥ 20000m 2 / kg) 2 parts, slag (specific surface area is 400m 2 / kg) 3 parts, heavy calcium (particle size: 400 mesh) 50 parts, acrylate copolymer (glass transition temperature -4 ℃) 0.8 parts, cellulose ether (viscosity 100000mPa.s) 0.3 parts, starch ether 0.03 parts , 0.3 part of wood fiber, 0.5 part of hydrophobic agent, 0.1 part of retarder. Mix the above components evenly to prepare the gypsum-based putty.

Embodiment 2

[0031] A kind of gypsum-based putty, comprising the following components by mass: 30 parts of β-type hemihydrate gypsum, gray calcium (the number of mesh is 450 mesh, Ca(OH) 2 Content ≥ 90%) 3 parts, silica fume (specific surface area ≥ 20000m 2 / kg) 2 parts, slag (specific surface area is 450m 2 / kg) 3 parts, heavy calcium (particle size: 500 mesh) 60 parts, acrylate copolymer (glass transition temperature -5 ℃) 1.5 parts, cellulose ether (viscosity 100000mPa.s) 0.3 parts, starch ether 0.03 parts , 0.2 part of wood fiber, 0.1 part of hydrophobic agent, 0.06 part of retarder. Mix the above components evenly to prepare the gypsum-based putty.

Embodiment 3

[0033] A kind of gypsum base putty, comprises the component of following mass parts: 32 parts of beta type hemihydrate gypsum, gray calcium (the mesh number is 450 orders, Ca(OH) 2 Content ≥ 90%) 7 parts, silica fume (specific surface area ≥ 20000m 2 / kg) 3 parts, slag (specific surface area is 450m 2 / kg) 5 parts, heavy calcium (particle size: 500 mesh) 51 parts, acrylate copolymer (glass transition temperature -4 ℃) 0.8 parts, cellulose ether (viscosity 40000mPa.s) 0.4 parts, starch ether 0.05 parts , 0.5 part of wood fiber, 0.4 part of hydrophobic agent, 0.07 part of retarder. Mix the above components evenly to prepare the gypsum-based putty.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com