Process for producing hydrogen by cooperatively using scenedesmus obliquus and fungus

A technology of Scenedesmus obliquus and process, applied in the biological field, can solve the problems of low hydrogen production efficiency of algae, and achieve the effects of good synergy performance, promotion of algal biomass, and good hydrogen production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The technique for synergistically producing hydrogen by using Scenedesmus obliquus and fungi comprises the following steps:

[0035] Preparation of composite bacterial solution: Enterococcus faecium and Rhodopseudomonas palustris were cultured separately to obtain 1×10 8 The seed liquid of CFU / ml is then mixed according to the volume ratio of 1:2 to obtain the mixed seed liquid, and then transferred to the fermentation medium according to the inoculation amount of 10%, and cultivated at 30°C for 12h to obtain the composite bacterial liquid; the fermentation medium The formula by mass percentage is: molasses 3%, corn steep liquor 2.5%, soybean meal 2%, K 2 HPO 4 0.1%, KH 2 PO 4 0.1%, CaCO 3 0.01%, FeSO 4 0.005%, MnSO 4 0.005%, the balance is water, pH7.0;

[0036] Preparation of algae liquid: Take Scenedesmus obliquus in the logarithmic growth phase, inoculate it into the TAP culture medium according to the inoculum amount of 5% for cultivation, and control th...

Embodiment 2

[0040] The technique for synergistically producing hydrogen by using Scenedesmus obliquus and fungi comprises the following steps:

[0041] Preparation of composite bacterial solution: Enterococcus faecium and Rhodopseudomonas palustris were cultured separately to obtain 1×10 8 The seed liquid of CFU / ml is then mixed according to the volume ratio of 1:2 to obtain the mixed seed liquid, and then transferred to the fermentation medium according to the inoculation amount of 10%, and cultivated at 30°C for 12h to obtain the composite bacterial liquid; the fermentation medium The formula by mass percentage is: molasses 3%, corn steep liquor 2.5%, soybean meal 2%, K 2 HPO 4 0.1%, KH 2 PO 4 0.1%, CaCO 3 0.01%, FeSO 4 0.005%, MnSO 4 0.005%, the balance is water, pH7.0;

[0042] Preparation of algae liquid: Take Scenedesmus obliquus in the logarithmic growth phase, inoculate it into the TAP culture medium according to the inoculum amount of 7% for cultivation, and control th...

Embodiment 3

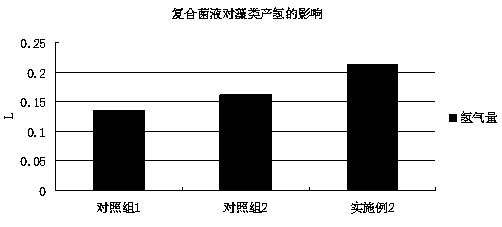

[0055] Hydrogen production performance test:

[0056] The liquid volume of setting reactor is 8L, and the space above liquid is 2L, and the amount of gas produced in the reaction process is obtained by multiplying the gas volume by the gas composition, and the gas phase product inside the reactor is measured by gas chromatography;

[0057] The hydrogen production and hydrogen content of Example 1 and Comparative Examples 1-2 were respectively detected; the concentration of algae cells in the culture solution was also detected by cell counting. See Table 1 for details:

[0058] Table 1

[0059] group

[0060] Conclusion: the amount of hydrogen produced in Example 1 of the present invention is significantly better than that of Comparative Example 1 and Comparative Example 2, and the concentration of algae cells is also better than that of Comparative Example 1 and Comparative Example 2. The activity of hydrogen-producing enzymes can increase the hydrogen production. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com