Copper graphite heat dissipation film and preparation method thereof

A technology of graphite heat dissipation film and graphite base material, which is applied in semiconductor/solid-state device manufacturing, superimposed layer plating, coating, etc., can solve the problems of reducing the machinability of heat sinks, high equipment requirements, and high cost, and achieves Ease of large-scale mass production, improved thermal conductivity, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

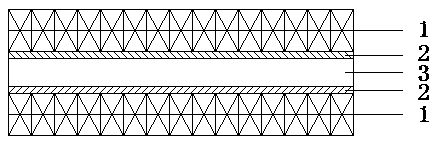

[0035] The copper-graphite heat dissipation film includes a graphite substrate layer, a metal transition layer and a metal copper layer, and the structural layer is a metal copper layer-nickel layer-graphite substrate layer-nickel layer-metal copper layer; wherein the metal transition layer is a metal Nickel, the thickness of a single layer is 0.1 μm; the thickness of a single layer of metal copper is 2 μm; the graphite substrate is roll-shaped natural graphite, with a thickness of 100 μm.

[0036] Preparation method, proceed as follows:

[0037] (1) drying the graphite substrate layer at 60°C for 24 hours;

[0038] (2) Surface treatment is performed on both sides of the graphite substrate after step (1) under the action of an ion source for 2 minutes;

[0039] (3) adopting the physical vapor deposition method, the graphite substrate after step (2) is double-sidedly coated with a metal transition layer;

[0040] (4) Using an electroless plating method, the surface of the met...

Embodiment 2

[0042] The copper-graphite heat dissipation film includes a graphite substrate layer, a metal transition layer and a metal copper layer, and the structural layer is a graphite substrate layer-silver copper layer-metal copper layer; wherein the metal transition layer is a combination of metal silver and copper, The thickness of a single layer is 0.5 μm; the thickness of a single layer of metallic copper is 4 μm; the graphite substrate is roll-shaped natural graphite with a thickness of 20 μm.

[0043] Preparation method, proceed as follows:

[0044] (1) drying the graphite substrate layer at 80° C. for 36 hours;

[0045] (2) The single side of the graphite substrate dried in step (1) is subjected to surface treatment under the action of plasma for 5 minutes;

[0046] (3) adopting the vacuum evaporation method, the graphite substrate after the step (2) is processed is coated with a metal transition layer on one side;

[0047] (4) Using an electroless plating method, the surfac...

Embodiment 3

[0049] The copper-graphite heat dissipation film includes a graphite substrate layer, a metal transition layer and a metal copper layer, and the structural layer is a graphite substrate layer-aluminum layer-metal copper layer; wherein the metal transition layer is metal aluminum, and the thickness of a single layer is 0.02 μm; the thickness of a single metal copper layer is 10 μm; the graphite substrate is roll-shaped synthetic graphite with a thickness of 200 μm.

[0050] Preparation method, proceed as follows:

[0051] (1) drying the graphite substrate layer at 100°C for 36 hours;

[0052] (2) surface-treating one side of the dried graphite substrate in step (1) under the action of an ion source for 10 minutes;

[0053] (3) adopting the vacuum evaporation method, the graphite substrate after the step (2) is processed is coated with a metal transition layer on one side;

[0054] (4) Using an electroplating method, the surface of the metal transition layer after plating in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com