Antistatic ABS (acrylonitrile butadiene styrene) compound, method for preparing same and application of antistatic ABS compound

A compound and antistatic technology, which is applied in the direction of acrylonitrile butadiene styrene polymer adhesives, circuits, electrical components, etc., can solve the problems of failure to meet the requirements of the storage battery field, explosion and fire of chemical product warehouses, static spark discharge, etc. problem, to achieve the effect of good antistatic effect, easy processing and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

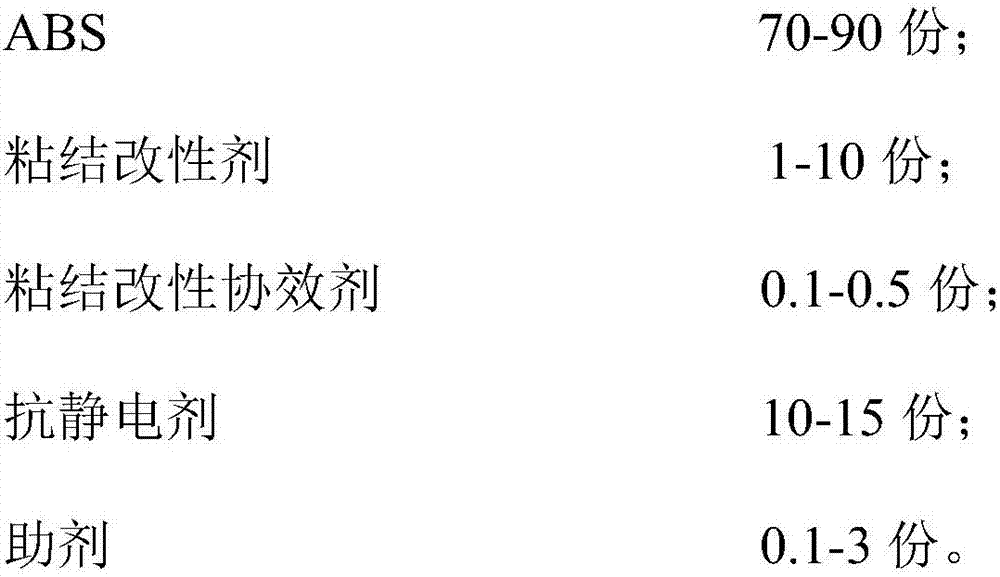

Method used

Image

Examples

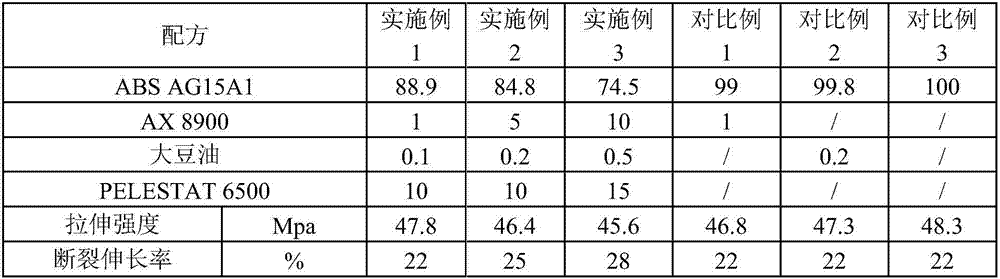

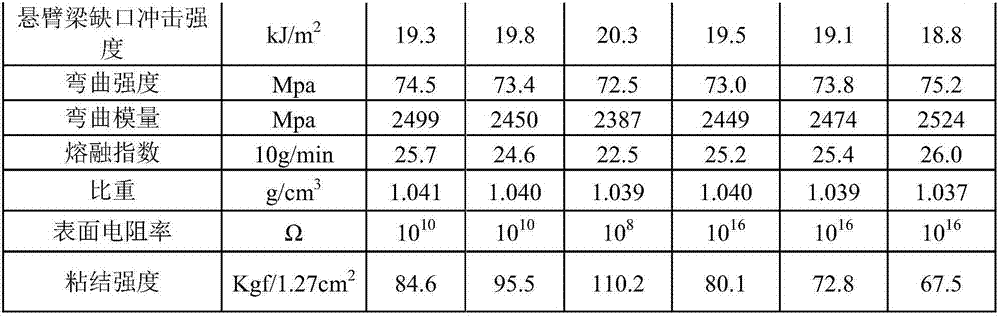

Embodiment 1

[0042] Mix 88.9 parts of ABS resin, 1 part of adhesion modifier, 0.1 part of adhesion modification synergist, and 10 parts of antistatic agent in a high-speed mixer for 10-60 minutes; pass the above mixture through a precision metering feeding device Transported in the twin-screw extruder (wherein, the processing conditions of twin-screw extruder melt extrusion are as follows: the temperature of the first zone is 190°C, the temperature of the second zone is 210°C, the temperature of the third zone is 230°C, the temperature of the fourth zone is 240°C, and the temperature of the fifth zone is 240°C. The temperature is 240°C, the temperature in the sixth zone is 240°C, the temperature in the seventh zone is 240°C, the temperature in the eighth zone is 240°C, the temperature in the ninth zone is 240°C, the temperature in the tenth zone is 250°C, the temperature of the head is 260°C; the screw speed is 200-800 rpm, The length-to-diameter ratio is 40:1), under the shearing, mixing a...

Embodiment 2

[0044] Mix 84.8 parts of ABS resin, 5 parts of adhesion modifier, 0.2 parts of adhesion modification synergist, and 10 parts of antistatic agent in a high-speed mixer for 10-60 minutes; pass the above mixture through a precision metering feeding device Transported in the twin-screw extruder (wherein, the processing conditions of twin-screw extruder melt extrusion are as follows: the temperature of the first zone is 190°C, the temperature of the second zone is 210°C, the temperature of the third zone is 230°C, the temperature of the fourth zone is 240°C, and the temperature of the fifth zone is 240°C. The temperature is 240°C, the temperature in the sixth zone is 240°C, the temperature in the seventh zone is 240°C, the temperature in the eighth zone is 240°C, the temperature in the ninth zone is 240°C, the temperature in the tenth zone is 250°C, the temperature of the head is 260°C; the screw speed is 200-800 rpm, The length-to-diameter ratio is 40:1), under the shearing, mixing...

Embodiment 3

[0046] Mix 74.5 parts of ABS resin, 10 parts of adhesion modifier, 0.5 parts of adhesion modification synergist, and 15 parts of antistatic agent in a high-speed mixer for 10-60 minutes; pass the above mixture through a precision metering feeding device Transported in the twin-screw extruder (wherein, the processing conditions of twin-screw extruder melt extrusion are as follows: the temperature of the first zone is 190°C, the temperature of the second zone is 210°C, the temperature of the third zone is 230°C, the temperature of the fourth zone is 240°C, and the temperature of the fifth zone is 240°C. The temperature is 240°C, the temperature in the sixth zone is 240°C, the temperature in the seventh zone is 240°C, the temperature in the eighth zone is 240°C, the temperature in the ninth zone is 240°C, the temperature in the tenth zone is 250°C, the temperature of the head is 260°C; the screw speed is 200-800 rpm, The length-to-diameter ratio is 40:1), under the shearing, mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com