Antistatic PA/ABS (polyamide/acrylonitrile butadiene styrene) compound, method for preparing same and application of antistatic PA/ABS compound

A compound and antistatic technology, which is applied in the direction of battery box/cover, acrylonitrile butadiene styrene polymer adhesive, circuit, etc., can solve the problems of failure to meet the requirements of the storage battery field, explosion and fire of chemical product warehouses, and material adsorption Dust and other problems, to achieve the effect of good antistatic effect, easy processing, high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

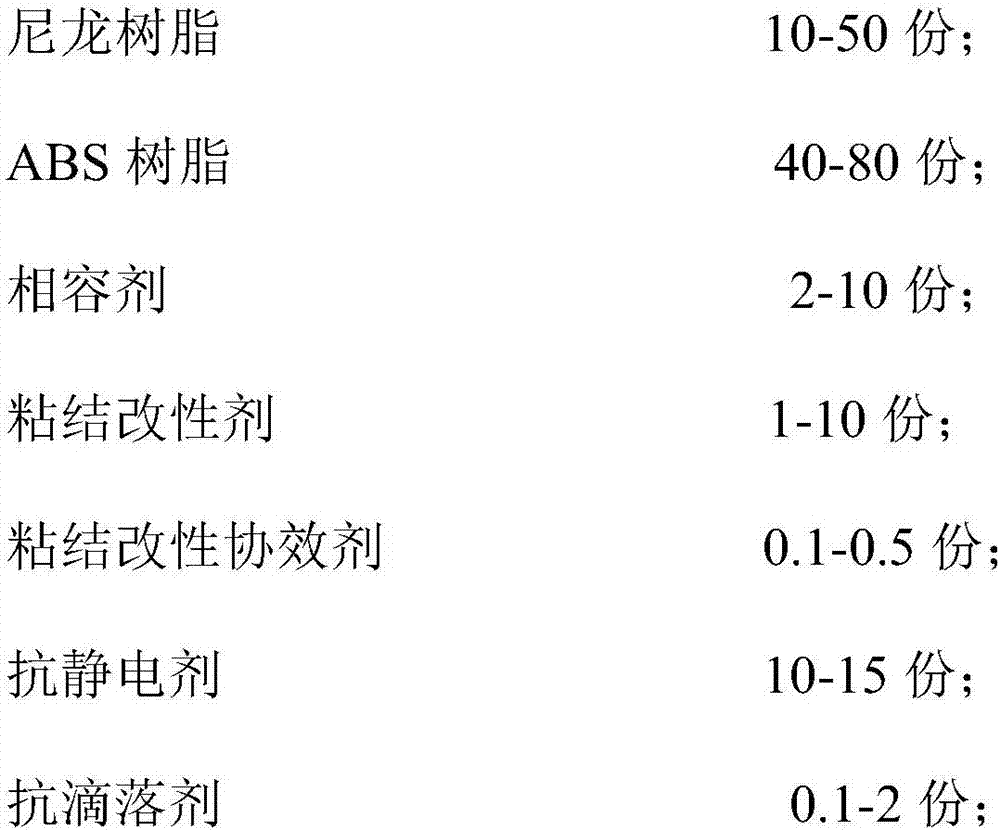

Method used

Image

Examples

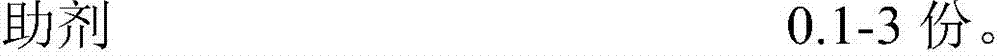

Embodiment 1

[0050]20 parts of PA6 resin, 63.9 parts of ABS resin, 5 parts of compatibilizer, 1 part of adhesion modifier, 10 parts of antistatic agent, 0.1 part of adhesion modification synergist, 0.8 parts of anti-dripping agent, according to the proportion Fully mix in a high-speed mixer for 10-60 minutes; deliver the above mixture to a twin-screw extruder through a precisely metered feeding device (wherein, the processing conditions for melt extrusion of the twin-screw extruder are as follows: the temperature in the first zone is 190 ° C, The temperature in the second zone is 210°C, the temperature in the third zone is 230°C, the temperature in the fourth zone is 240°C, the temperature in the fifth zone is 240°C, the temperature in the sixth zone is 240°C, the temperature in the seventh zone is 240°C, the temperature in the eighth zone is 240°C, the temperature in the ninth zone is 240°C, the temperature in the tenth zone The temperature is 250°C, the head temperature is 260°C; the scre...

Embodiment 2

[0052] 20 parts of PA6 resin, 79.8 parts of ABS resin, 5 parts of compatibilizer, 5 parts of adhesion modifier, 10 parts of antistatic agent, 0.2 parts of adhesion modification synergist, 1.0 part of anti-dripping agent, according to the proportion Fully mix in a high-speed mixer for 10-60 minutes; deliver the above mixture to a twin-screw extruder through a precisely metered feeding device (wherein, the processing conditions for melt extrusion of the twin-screw extruder are as follows: the temperature in the first zone is 190 ° C, The temperature in the second zone is 210°C, the temperature in the third zone is 230°C, the temperature in the fourth zone is 240°C, the temperature in the fifth zone is 240°C, the temperature in the sixth zone is 240°C, the temperature in the seventh zone is 240°C, the temperature in the eighth zone is 240°C, the temperature in the ninth zone is 240°C, the temperature in the tenth zone The temperature is 250°C, the head temperature is 260°C; the sc...

Embodiment 3

[0054] 20 parts of PA6 resin, 49.5 parts of ABS resin, 5 parts of compatibilizer, 10 parts of adhesion modifier, 15 parts of antistatic agent, 0.5 parts of adhesion modification synergist, 1.9 parts of anti-dripping agent, according to the proportion Fully mix in a high-speed mixer for 10-60 minutes; deliver the above mixture to a twin-screw extruder through a precisely metered feeding device (wherein, the processing conditions for melt extrusion of the twin-screw extruder are as follows: the temperature in the first zone is 190 ° C, The temperature in the second zone is 210°C, the temperature in the third zone is 230°C, the temperature in the fourth zone is 240°C, the temperature in the fifth zone is 240°C, the temperature in the sixth zone is 240°C, the temperature in the seventh zone is 240°C, the temperature in the eighth zone is 240°C, the temperature in the ninth zone is 240°C, the temperature in the tenth zone The temperature is 250°C, the head temperature is 260°C; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com