Reactive dye printed fabric color-increasing brightening finishing agent and preparation method

A technology of reactive dyes and finishing agents, which is applied in dyeing, textiles and papermaking, etc. It can solve problems that affect the promotion and use of products, contain ammonia nitrogen groups, and cannot meet the increasingly strict requirements of environmental protection, etc., to increase the combination fastness, The effect of reducing reflectivity and increasing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

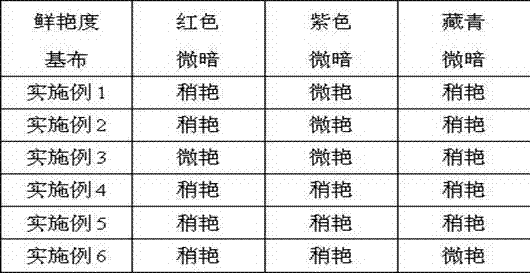

Examples

Embodiment 1

[0030] 1. Fully stir 15 parts of isomeric C13 alcohol polyoxyethylene (12) ether, 5 parts of C12-C14 secondary alcohol polyoxyethylene (5) ether and 12 parts of deionized water at room temperature for 25 minutes to make the mixture form a colorless transparent viscous paste;

[0031] 2. Then add 50 parts of methyl silicone oil with a viscosity of 1000mpa.s, 200 parts of hydroxy silicone oil with a viscosity of 10000mpa.s, 12 parts of methyl hydrogen-containing silicone oil, 25 parts of refined castor oil, and 2 parts of ethyl silicate-40. Continue stirring for 30 minutes at room temperature to form a transparent sticky fat;

[0032] 3. Finally, add 572 parts of deionized water to the mixture at one time, stir rapidly for 20 minutes to form a milky white emulsion, and obtain a darkening and brightening finishing agent product.

Embodiment 2

[0034] 1. Fully stir 10 parts of isomeric C13 alcohol polyoxyethylene (7) ether, 20 parts of C12-C14 secondary alcohol polyoxyethylene (9) ether and 30 parts of deionized water at room temperature for 30 minutes to make the mixture form a colorless transparent viscous paste;

[0035] 2. Then add 60 parts of methyl silicone oil with a viscosity of 350mpa.s, 190 parts of hydroxy silicone oil with a viscosity of 20000mpa.s, 9.5 parts of methyl hydrogen-containing silicone oil, 28 parts of refined castor oil, and 3.8 parts of ethyl silicate-40. Continue stirring for 40 minutes at room temperature to form a transparent sticky fat;

[0036] 3. Finally, add 630 parts of deionized water to the mixture at one time, stir rapidly for 25 minutes to form a milky white emulsion, and obtain a darkening and brightening finishing agent product.

Embodiment 3

[0038] 1. Fully stir 15 parts of isomeric C13 alcohol polyoxyethylene (5) ether, 10 parts of C12-C14 secondary alcohol polyoxyethylene (12) ether and 25 parts of deionized water at room temperature for 20 minutes to make the mixture form a colorless transparent viscous paste;

[0039] 2. Then add 55 parts of methyl silicone oil with a viscosity of 500mpa.s, 220 parts of hydroxy silicone oil with a viscosity of 50000mpa.s, 9 parts of methyl hydrogen-containing silicone oil, 30 parts of refined castor oil, and 4.5 parts of ethyl silicate-40. Continue stirring for 40 minutes at room temperature to form a transparent sticky fat;

[0040] 3. Finally, add 620 parts of deionized water to the mixture at one time, stir rapidly for 30 minutes to form a milky white emulsion, and obtain a darkening and brightening finishing agent product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com