Disposal method of waste lithium ion battery

A technology of lithium ion battery and treatment method, applied in the field of solid waste recycling and treatment, can solve the problem of low degree of harmlessness, and achieve the effect of being easy to engineer and suitable for large-scale industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

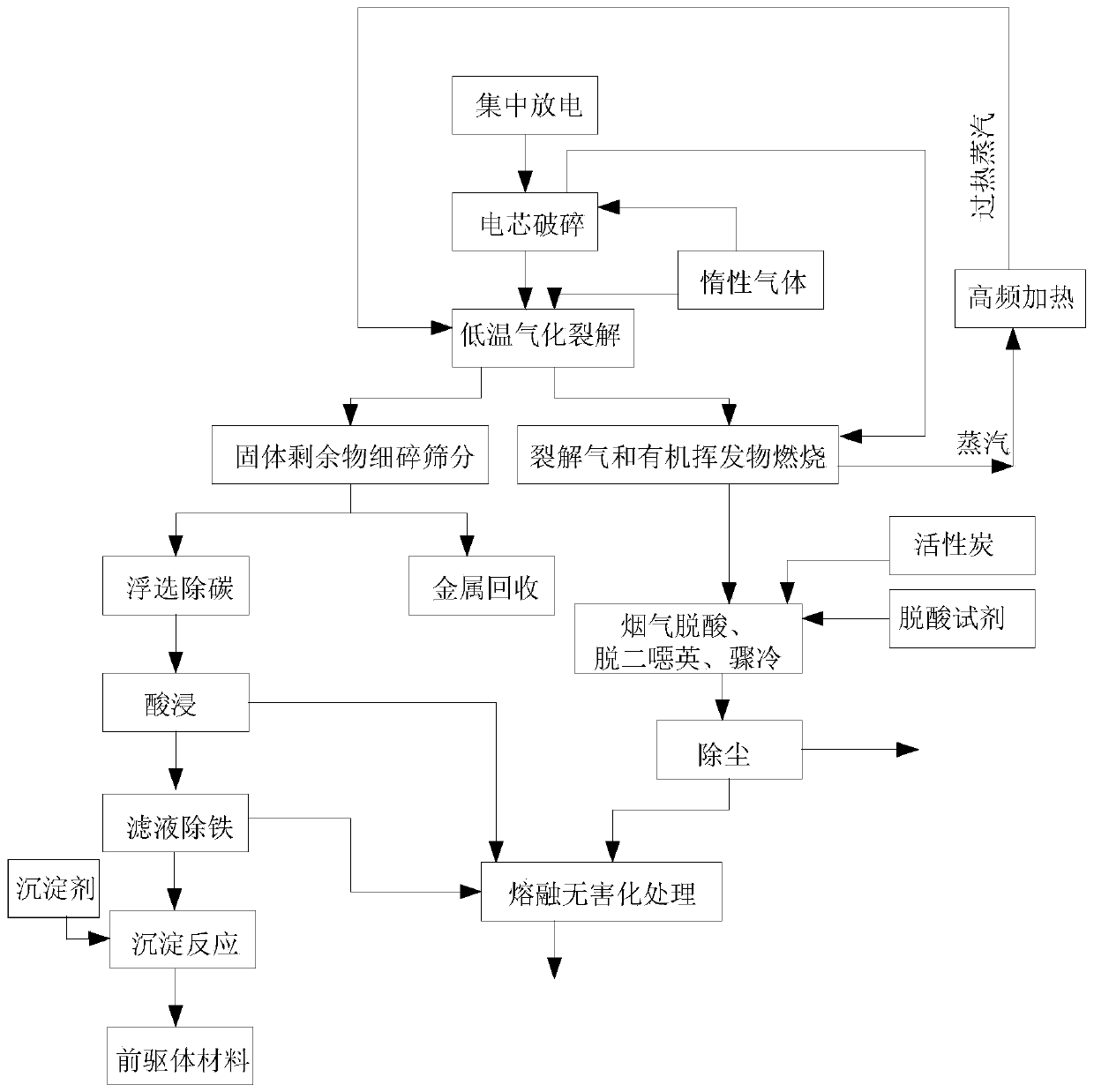

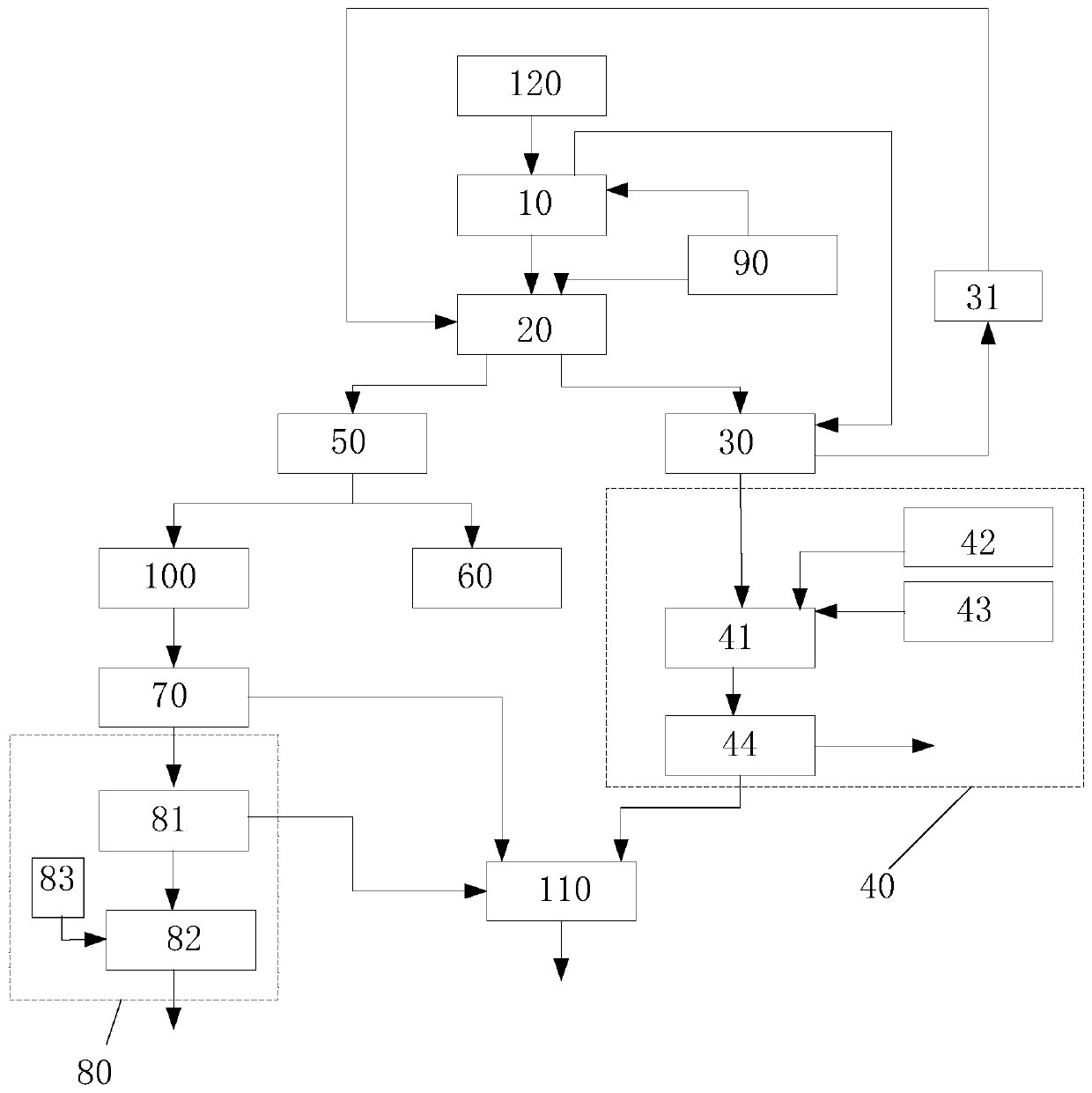

Method used

Image

Examples

Embodiment 1

[0061] After the waste lithium-ion batteries are intensively discharged, they are sent to the nitrogen-protected crushing system for coarse crushing. The particle size is controlled at 2-3 cm, and the temperature during crushing is controlled below 25°C. The volatile organic gas generated during crushing is sent to the cracked gas secondary combustion system.

[0062] The crushed cell scraps are sealed and put into a low-temperature gasification cracking furnace under a nitrogen atmosphere, and the cracking temperature is 550°C. The inlet and outlet of the low-temperature gasification cracking furnace are sealed with double-layer nitrogen. The superheated saturated steam passed into the furnace is gasified and cracked at low temperature with the battery scraps to obtain cracked gas and solid residues, specifically: organic matter in the electrolyte, binder PVDF, etc. undergo cracking and gasification reactions to generate methane, ethane, etc. Alkane gas and some olefin gas, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com