Water-soluble fluorescent liquid metal material and preparation method thereof

A liquid metal, water-soluble technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of non-water-soluble liquid metal fluorescent materials and lack of fluorescent properties, and achieve improved wettability, multiple display functions, and reduced wetness. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

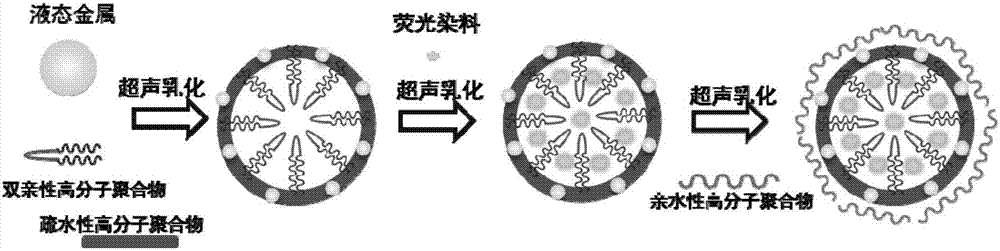

[0046] The preparation process is as figure 1 , specifically the following steps:

[0047] (1) Prepare 20mg / mL Pluronic F127 (molecular weight 12.7KD) solution and 10mg / mL PLGA (molecular weight 13KD) solution, the solvent is dichloromethane; 80μL liquid metal Ga 75.5 In 24.5 Add 2mL of the mixed solution of Pluronic F127 and PLGA and sonicate for 3min with a power of 120W.

[0048] (2) Dissolve 10 mg of fluorescent dye ICG in 1 mL of deionized water;

[0049] (3) Add the fluorescent dye solution dropwise to the mixed solution described in step (1), and sonicate for 2 minutes;

[0050] (4) Prepare 4ml of 2% polyvinyl alcohol (molecular weight 9.5KD) aqueous solution, add the mixed solution in step (3), and continue ultrasonication for 2 minutes;

[0051] (5) The emulsion is transferred to a rotary evaporator, and the vacuum is turned on until the methylene chloride organic solvent is completely removed, and the emulsion becomes clear;

[0052] The reaction solution was pl...

Embodiment 2

[0056] This embodiment is a method for preparing a water-soluble liquid metal fluorescent material, which specifically includes the following steps:

[0057] (1) Prepare 20mg / mL Pluronic F127 solution and 20mg / mL PLGA solution, the solvent is dichloromethane; 80μL liquid metal Ga 70 In 30 Add 2ml Pluronic F127 and PLGA mixed solution and sonicate for 3min;

[0058] (2) Dissolve 10 mg of fluorescent dye ICG in 1 ml of deionized water;

[0059] (3) drop the fluorescent dye into the mixed solution described in step (1), and sonicate for 2 minutes;

[0060] (4) Prepare 4ml of 2% polyvinyl alcohol solution, add the mixed solution in step (3), and continue ultrasonication for 2min;

[0061] (5) The emulsion is transferred to a rotary evaporator, and the vacuum is turned on until the methylene chloride organic solvent is completely removed, and the emulsion becomes clear;

[0062] The reaction solution was placed in a centrifuge tube, and the final product was obtained by high-sp...

Embodiment 3

[0065] This embodiment is a method for preparing a water-soluble liquid metal fluorescent material, which specifically includes the following steps:

[0066] (1) Prepare 20mg / mL Pluronic F127 solution and 10mg / mL PLGA solution, the solvent is dichloromethane; 100μL liquid metal Ga 75.5 In 24.5 Add 2ml Pluronic F127 and PLGA mixed solution and sonicate for 3min;

[0067] (2) Dissolve 10 mg of fluorescent dye ICG in 1 mL of deionized water;

[0068] (3) drop the fluorescent dye into the mixed solution described in step (1), and sonicate for 2 minutes;

[0069] (4) Prepare 4 mL of 2% polyvinyl alcohol solution, add the mixed solution in step (3), and continue to sonicate for 2 minutes;

[0070] (5) The emulsion is transferred to a rotary evaporator, and the vacuum is turned on until the methylene chloride organic solvent is completely removed, and the emulsion becomes clear;

[0071] The reaction solution was placed in a centrifuge tube, and the final product was obtained by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com