Catalyst for liquid-phase selective hydrogenation of alkynes and dialkenes, and preparation method and application thereof

A hydrogenation catalyst and diene liquid technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the difficulty of large-scale industrialization and reduce reaction options Problems such as stability and coking degree are reduced, and the effects of prolonging the stable operation period, reducing the degree of aggregation, and improving the hydrogenation capacity are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

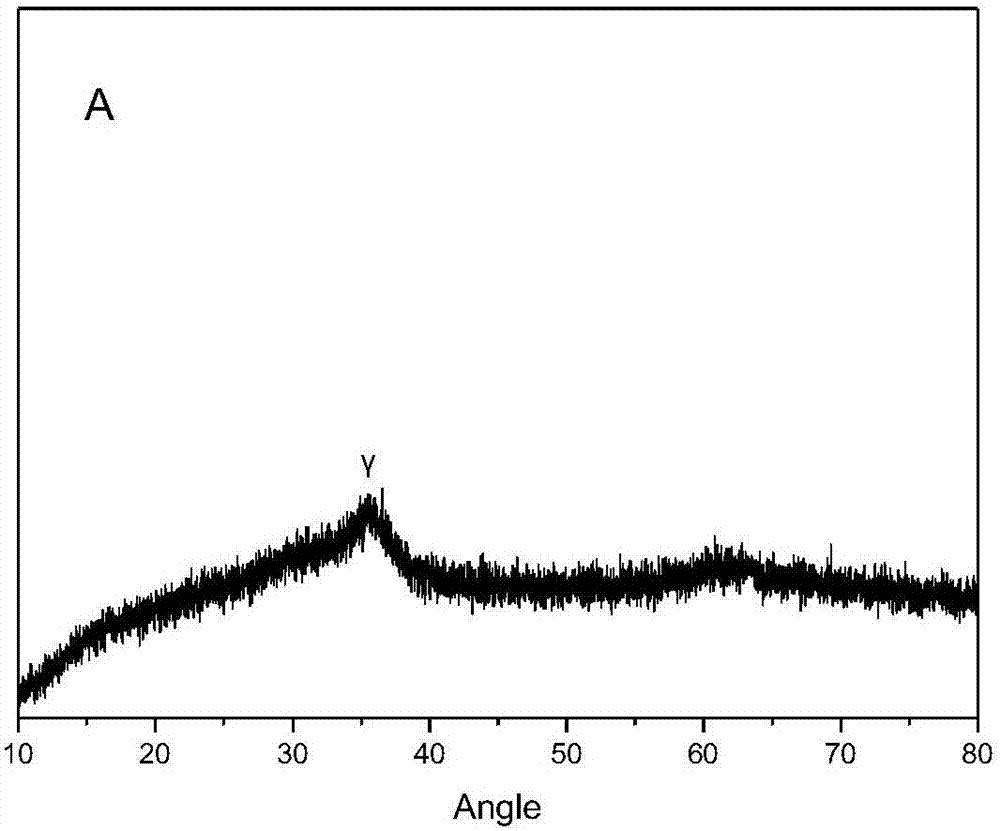

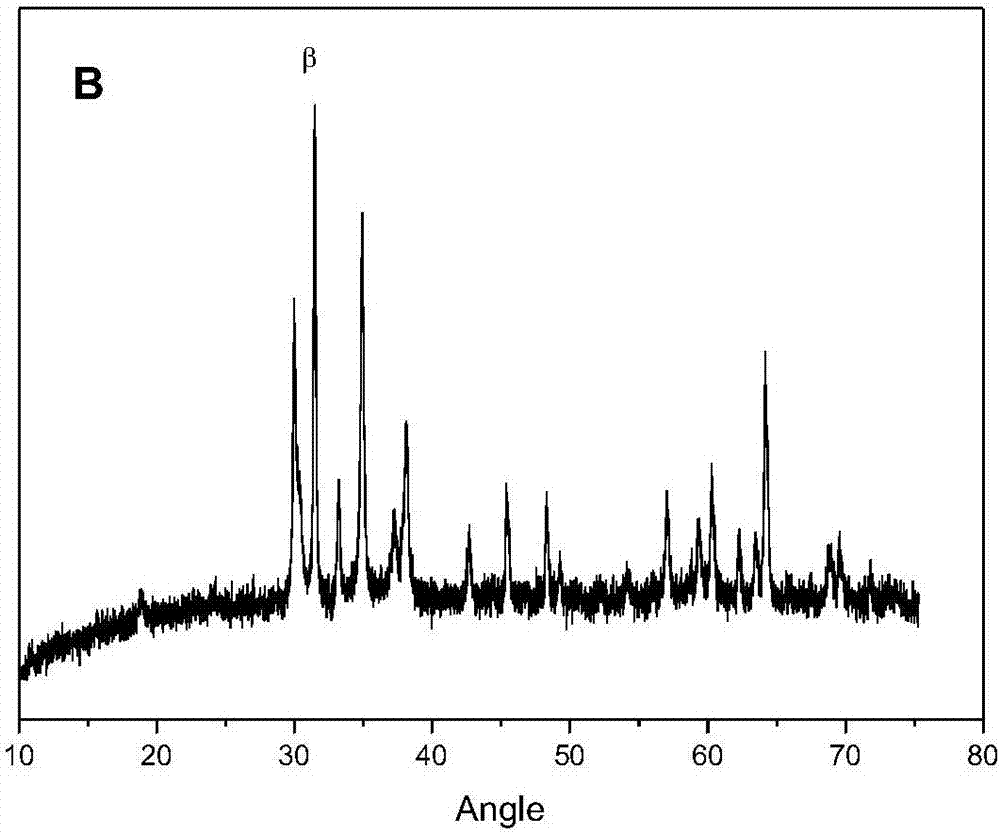

Embodiment 1

[0058] ① Preparation of Bi(NO 3 ) 3 and KNO containing 2.5gK 3 200ml of aqueous solution, 500g of spherical carrier Al 2 o 3 Immersed in the aqueous solution, dried at 105°C, and calcined at 1000°C to obtain Bi and K modified carrier Al 2 o 3 , with a specific surface area of 450m 2 / g;

[0059] ② Preparation of Pd(NO 3 ) 2 200ml of aqueous solution, the Bi and K modified carrier Al 2 o 3 Immerse in the solution, dry at 105°C, and bake at 500°C to obtain Pd / Al 2 o 3 catalyst;

[0060] ③ Preparation of GaCl containing 1gGa 3 200ml of aqueous solution, the solution is sprayed on Pd / Al 2 o 3 On the catalyst, dry at 105°C and bake at 350°C to obtain Pd-Ga 2 o 3 / Al 2 o 3 catalyst;

[0061] ④ In an adiabatic fixed-bed reactor, use a mixed gas of methane and hydrogen containing 90% hydrogen to reduce at 320°C for 6 hours with a temperature control range of ±1°C to obtain catalyst NC3-1, wherein the Pd content is 0.1wt%, Ga content is 0.2wt%, Bi content is 1wt%...

Embodiment 2

[0063] ① Preparation of Zn(NO 3 ) 2 and MgCl with 2.5 gMg 2 250ml of aqueous solution, 500g tooth carrier Al 2 o 3 Immersed in the aqueous solution, dried at 110°C, and calcined at 1100°C to obtain Zn and Mg modified carrier Al 2 o 3 , with a specific surface area of 120m 2 / g;

[0064] ② Preparation of [(NH 4 ) 2 Pd]Cl 4 250ml of aqueous solution, Zn and Mg modified carrier Al 2 o 3 Immerse in the solution, dry at 105°C, and bake at 550°C to obtain Pd / Al 2 o 3 catalyst;

[0065] ③ Preparation of Ga(NO) containing 0.5gGa 3 ) 3 278ml of ethanol solution, the solution is impregnated in Pd / Al 2 o 3 On the catalyst, dry at 90°C and bake at 430°C to obtain Pd-Ga 2 o 3 / Al 2 o 3 catalyst;

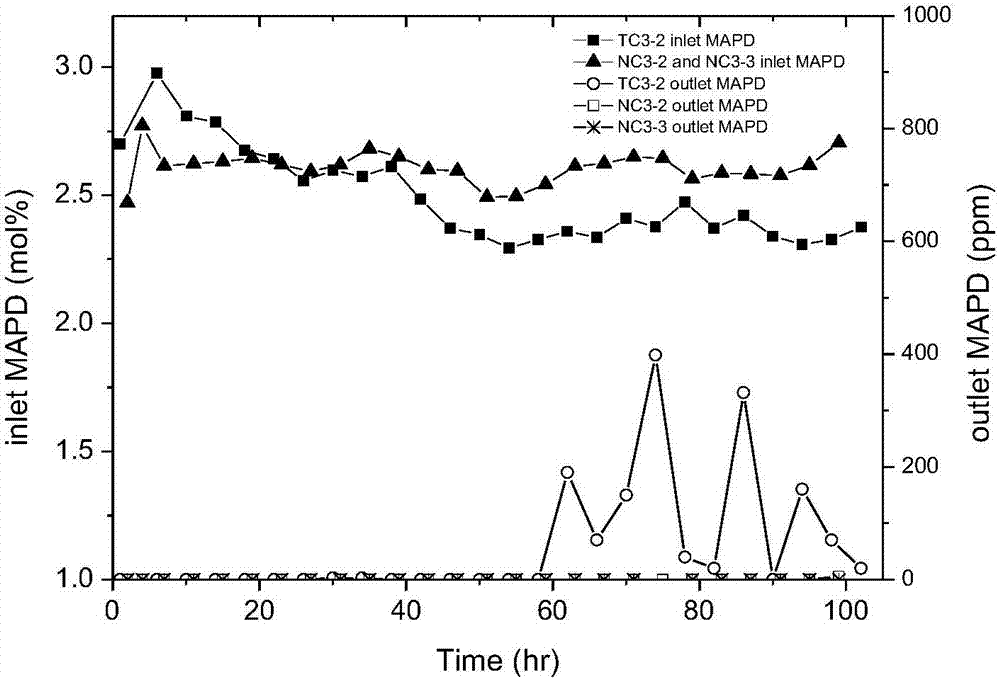

[0066] ④ In an adiabatic fixed-bed reactor, use a mixed gas of nitrogen and hydrogen containing 70% hydrogen to reduce at 270°C for 4 hours, and the temperature control range is ±1°C to obtain catalyst NC3-2, wherein the Pd content is 0.06wt%. The Ga content is 0.1 wt%, t...

Embodiment 3

[0068] ⑤ Preparation of HAuCl containing 1gAu 4 235ml of n-butanol solution, 500g column carrier Al 2 o 3 Immersed in the solution, dried at 130°C, and calcined at 1070°C to obtain Au-modified carrier Al 2 o 3 , with a specific surface area of 340m 2 / g;

[0069] ⑥ Preparation of PdCl containing 0.375gPd 2 265ml of aqueous solution, the Au-modified carrier Al 2 o 3 Immerse in the solution, dry at 105°C, and bake at 520°C to obtain Pd / Al 2 o 3 catalyst;

[0070] ⑦Prepare 265ml of an aqueous solution of gallium trifluoromethanesulfonate containing 0.65gGa, and impregnate the solution in Pd / Al 2 o 3On the catalyst, dry at 120°C and bake at 370°C to obtain Pd-Ga 2 o 3 / Al 2 o 3 catalyst;

[0071] 8. In an adiabatic fixed-bed reactor, use a mixed gas of nitrogen and hydrogen containing 85% hydrogen to reduce at 300° C. for 8 hours with a temperature control range of ± 1° C. to obtain catalyst NC3-3, wherein the Pd content is 0.075 wt %, The Ga content is 0.13 wt%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com