Heterogeneous oxidative desulfurization catalyst and preparation method thereof

An oxidative desulfurization and catalyst technology, which is applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of limited application range, limited mass transfer, poor stability of active components, etc., to improve the surface environment , reduce mass transfer resistance, enhance the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

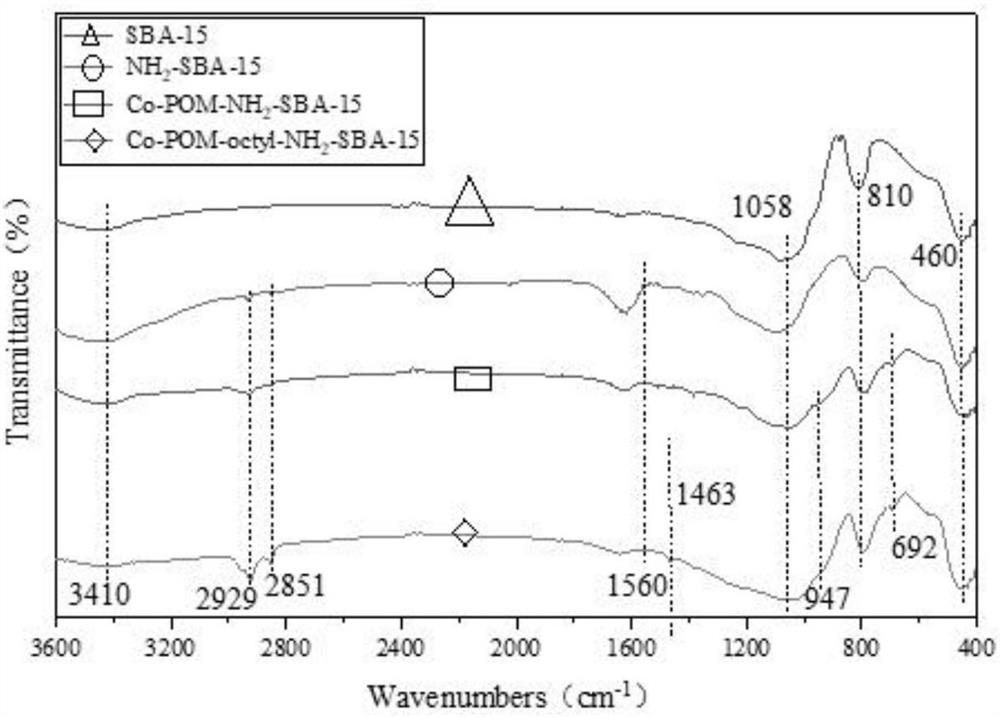

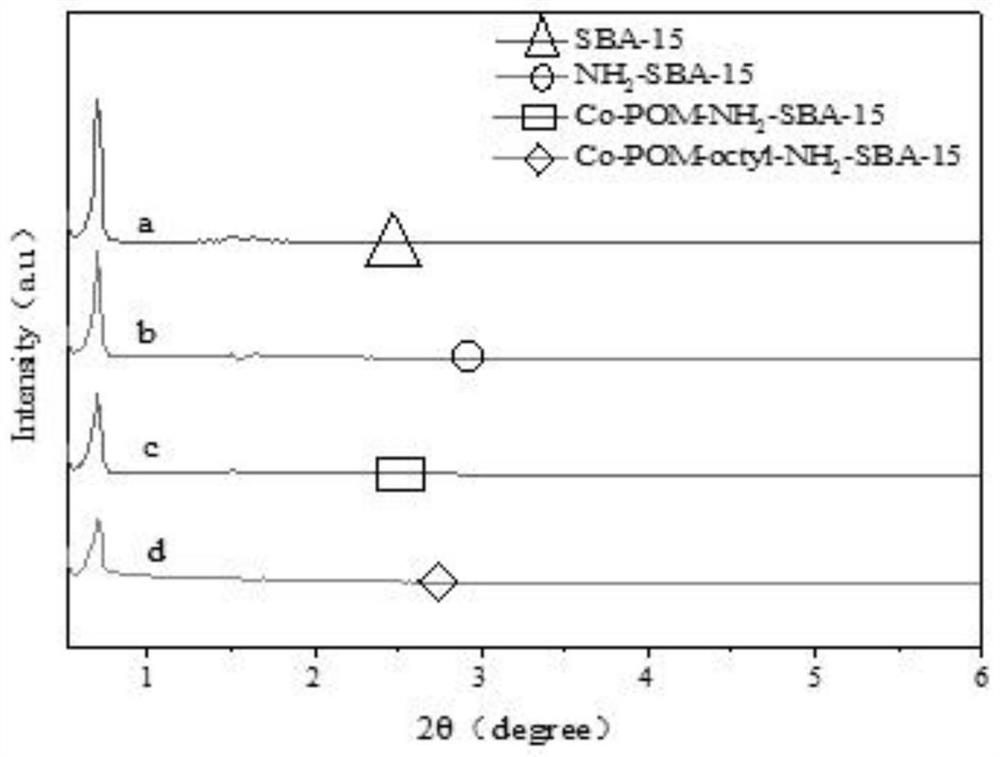

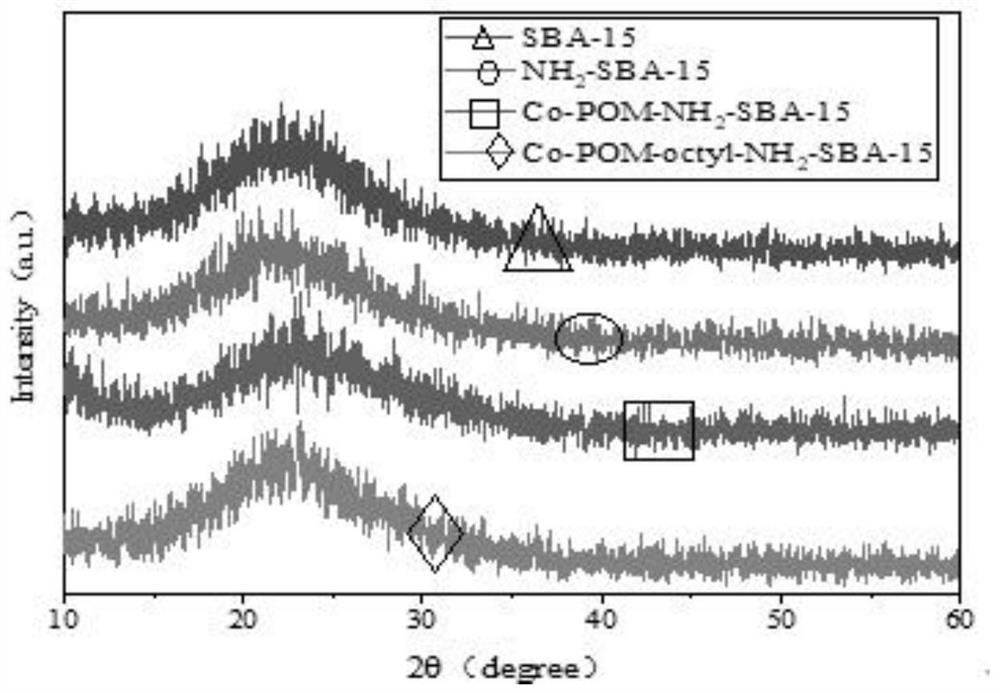

[0044] This paper discloses a preparation method of a heterogeneous oxidative desulfurization catalyst, comprising the following steps:

[0045] Step (a) preparing transition metal-modified phosphomolybdenum heteropolyacids by hydrothermal synthesis;

[0046] Step (b) modifying the hydrophobic group onto the mesoporous material to obtain a functionalized carrier one;

[0047] Step (c) modifying the active group on the carrier 1 to obtain the carrier 2;

[0048] Step (d) load the phosphomolybdenum heteropoly acid on the carrier 2 to obtain the final product.

[0049] The embodiment of the present invention also discloses a preparation method of a heterogeneous oxidative desulfurization catalyst, comprising the following steps:

[0050] Step (e) preparing transition metal-modified phosphomolybdenum heteropolyacids by hydrothermal synthesis;

[0051] Step (f) modifying the hydrophobic group onto the mesoporous material to obtain a functionalized carrier 3;

[0052] Step (g) L...

Embodiment 1

[0078] On the basis of the disclosed embodiments, a method for preparing a heterogeneous oxidative desulfurization catalyst is disclosed, and the above steps (a), step (e) and step (h) also include the following steps:

[0079] (1) prepare respectively containing phosphate, transition metal salt and molybdate solution;

[0080] (2) Mix and cool the phosphate and transition metal salt solutions, adjust the pH value to 0.5, and add concentrated sulfuric acid dropwise until the mixed solution is clear to obtain mixed solution 1;

[0081] (3) After the mixed solution is extracted with an organic solvent, it is separated and dried at low temperature to obtain the molybdophosphopolyacid.

[0082] Preferably, the organic solvent includes ether; the drying temperature is 60°C; the phosphate-containing salt is H 2 PO 4 - 、HPO 4 2- 、PO 4 3- ; The transition metal salt is Co(NO 3 ) 2 ·6H 2 O; the molybdate is Na 2 MoO 4 ·H 2 O.

[0083] Preferably, said step (b), step (c), ...

Embodiment 2

[0099] On the basis of the disclosed embodiments, a method for preparing a heterogeneous oxidative desulfurization catalyst is disclosed, and the above steps (a), step (e) and step (h) also include the following steps:

[0100] (1) prepare respectively containing phosphate, transition metal salt and molybdate solution;

[0101] (2) Mix and cool the phosphate and transition metal salt solutions, adjust the pH value to 2.5, and add concentrated sulfuric acid dropwise until the mixed solution is clear to obtain mixed solution 1;

[0102] (3) After the mixed solution is extracted with an organic solvent, it is separated and dried at low temperature to obtain the molybdophosphopolyacid.

[0103] Preferably, the organic solvent includes ether; the drying temperature is 100°C; the phosphate-containing salt includes H 2 PO 4 - 、HPO 4 2- 、PO 4 3- ; The transition metal salt comprises Co(NO 3 ) 2 ·6H 2 O; the molybdate comprises Na 2 MoO 4 ·H 2 O.

[0104] Preferably, said...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com