A kind of liquid-phase selective hydrogenation catalyst of alkyne and diene, preparation method and application

A hydrogenation catalyst and diene liquid technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of reducing the degree of coking, reducing the reaction selectivity, Large-scale industrialization is difficult and other problems, to achieve the effect of good hydrogenation capacity, reducing the degree of aggregation, and prolonging the stable operation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

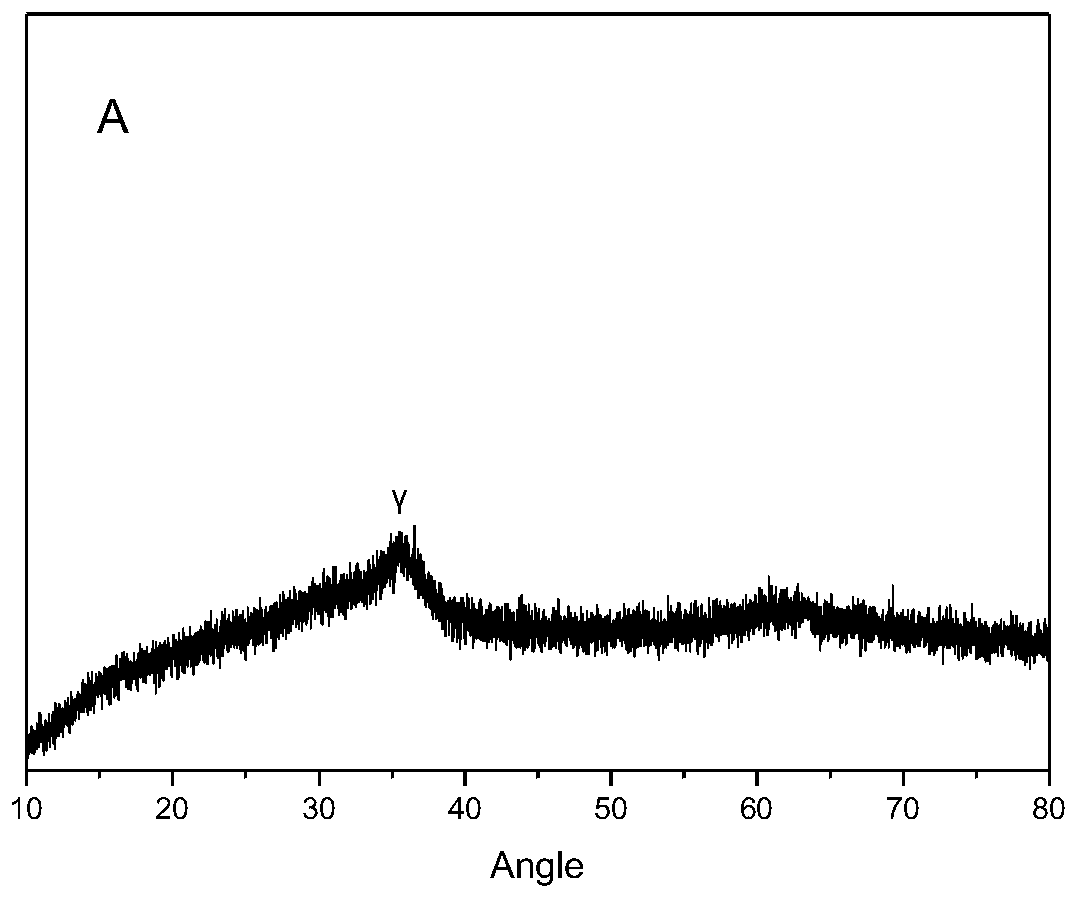

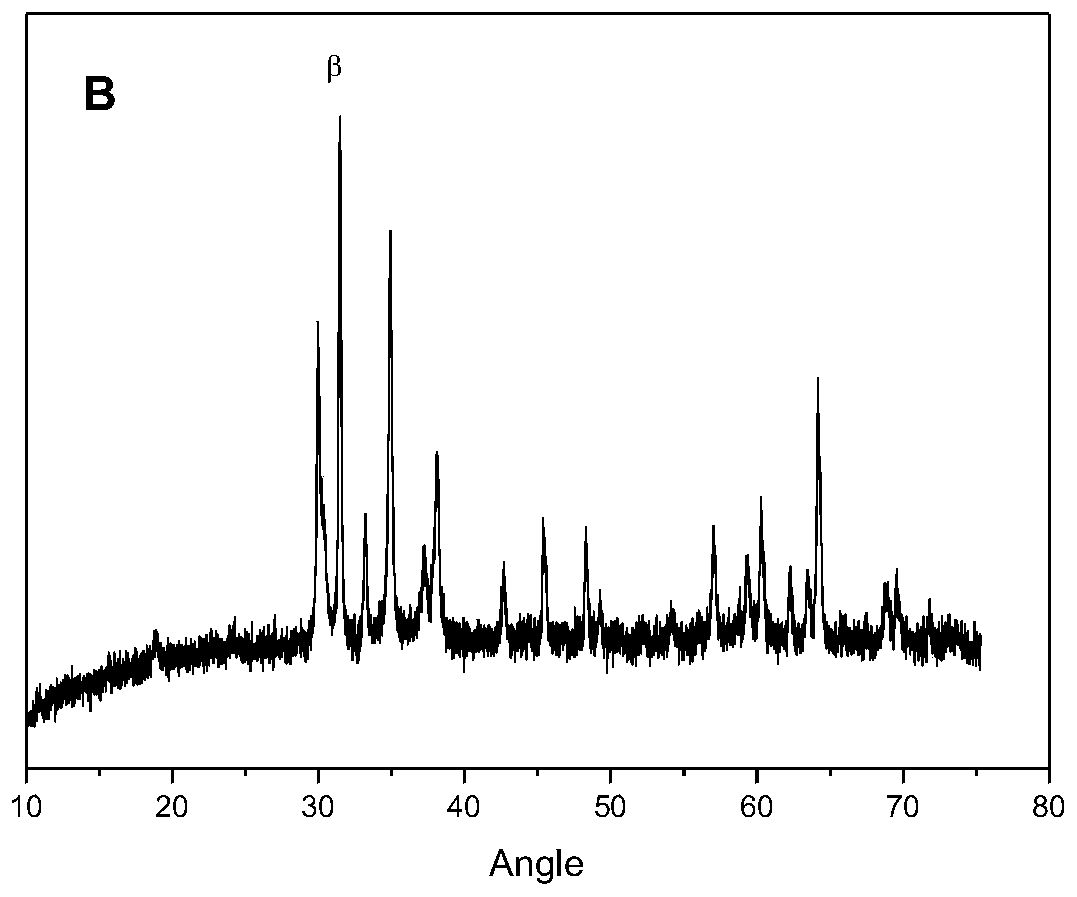

Embodiment 1

[0058] ① Preparation of Bi(NO 3 ) 3 and KNO containing 2.5gK 3 200ml of aqueous solution, 500g of spherical carrier Al 2 o 3 Immersed in the aqueous solution, dried at 105°C, and calcined at 1000°C to obtain Bi and K modified carrier Al 2 o 3 , with a specific surface area of 450m 2 / g;

[0059] ② Preparation of Pd(NO 3 ) 2 200ml of aqueous solution, the Bi and K modified carrier Al 2 o 3 Immerse in the solution, dry at 105°C, and bake at 500°C to obtain Pd / Al 2 o 3 catalyst;

[0060] ③ Preparation of GaCl containing 1gGa 3 200ml of aqueous solution, the solution is sprayed on Pd / Al 2 o 3 On the catalyst, dry at 105°C and bake at 350°C to obtain Pd-Ga 2 o 3 / Al 2 o 3 catalyst;

[0061] ④ In an adiabatic fixed-bed reactor, use a mixed gas of methane and hydrogen containing 90% hydrogen to reduce at 320°C for 6 hours with a temperature control range of ±1°C to obtain catalyst NC3-1, wherein the Pd content is 0.1wt%, Ga content is 0.2wt%, Bi content is 1wt%...

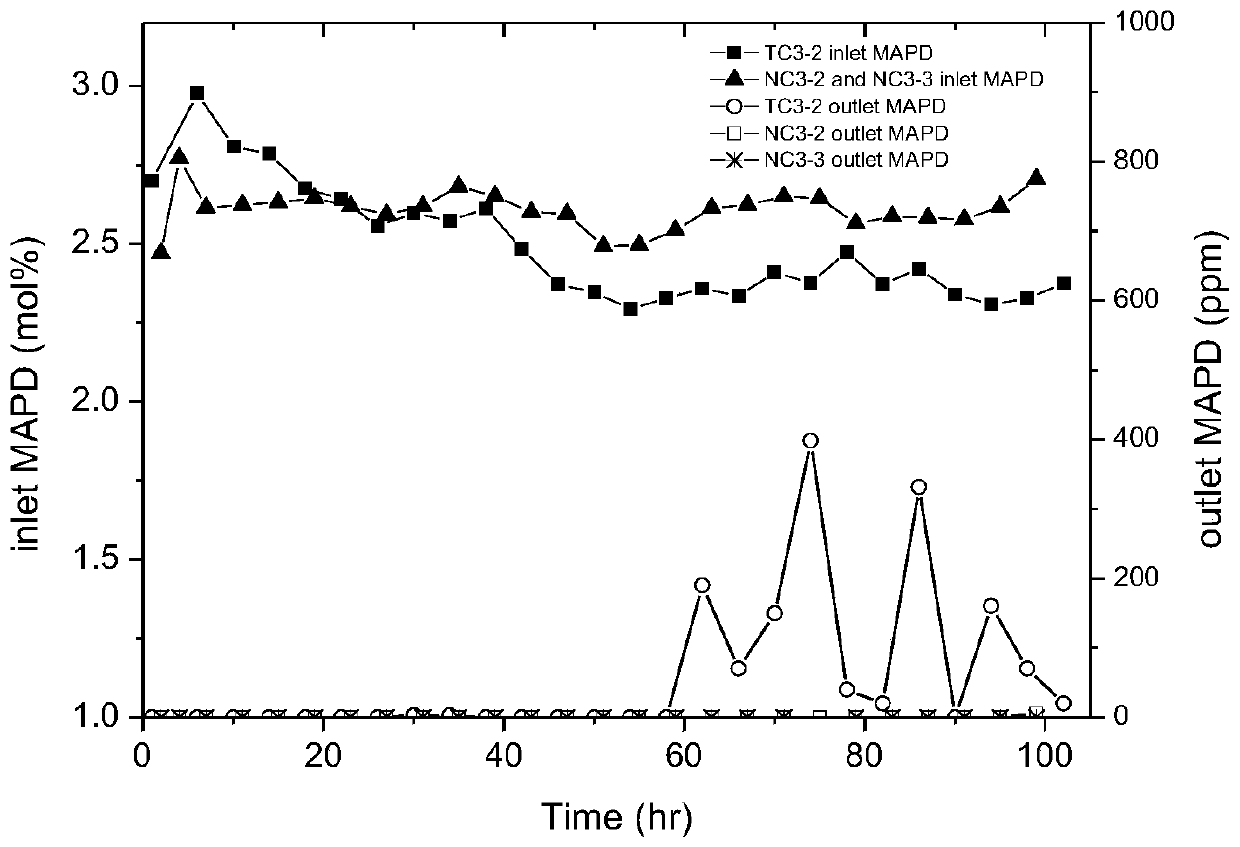

Embodiment 2

[0063] ① Preparation of Zn(NO 3 ) 2 and MgCl with 2.5 gMg 2 250ml of aqueous solution, 500g tooth carrier Al 2 o 3 Immersed in the aqueous solution, dried at 110°C, and calcined at 1100°C to obtain Zn and Mg modified carrier Al 2 o 3 , with a specific surface area of 120m 2 / g;

[0064] ② Preparation of [(NH 4 ) 2 Pd]Cl 4 250ml of aqueous solution, Zn and Mg modified carrier Al 2 o 3 Immerse in the solution, dry at 105°C, and bake at 550°C to obtain Pd / Al 2 o 3 catalyst;

[0065] ③ Preparation of Ga(NO) containing 0.5gGa 3 ) 3 278ml of ethanol solution, the solution is impregnated in Pd / Al 2 o 3 On the catalyst, dry at 90°C and bake at 430°C to obtain Pd-Ga 2 o 3 / Al 2 o 3 catalyst;

[0066] ④ In an adiabatic fixed-bed reactor, use a mixed gas of nitrogen and hydrogen containing 70% hydrogen to reduce at 270°C for 4 hours, and the temperature control range is ±1°C to obtain catalyst NC3-2, wherein the Pd content is 0.06wt%. The Ga content is 0.1 wt%, t...

Embodiment 3

[0068] ⑤ Preparation of HAuCl containing 1gAu 4 235ml of n-butanol solution, 500g column carrier Al 2 o 3 Immersed in the solution, dried at 130°C, and calcined at 1070°C to obtain Au-modified carrier Al 2 o 3 , with a specific surface area of 340m 2 / g;

[0069] ⑥ Preparation of PdCl containing 0.375gPd 2 265ml of aqueous solution, the Au-modified carrier Al 2 o 3 Immerse in the solution, dry at 105°C, and bake at 520°C to obtain Pd / Al 2 o 3 catalyst;

[0070] ⑦Prepare 265ml of an aqueous solution of gallium trifluoromethanesulfonate containing 0.65gGa, and impregnate the solution in Pd / Al 2 o 3On the catalyst, dry at 120°C and bake at 370°C to obtain Pd-Ga 2 o 3 / Al 2 o 3 catalyst;

[0071] 8. In an adiabatic fixed-bed reactor, use a mixed gas of nitrogen and hydrogen containing 85% hydrogen to reduce at 300° C. for 8 hours with a temperature control range of ± 1° C. to obtain catalyst NC3-3, wherein the Pd content is 0.075 wt %, The Ga content is 0.13 wt%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com