Method for preparing basic cerium carbonate with high rare earth content

A high rare earth content, cerium carbonate technology, applied in rare earth metal carbonates, rare earth metal compounds, chemical instruments and methods, etc., can solve the problems of inability to realize industrialized production, inability to quickly add precipitants, low production efficiency, etc. The effect of reducing pure water consumption, reducing energy consumption and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

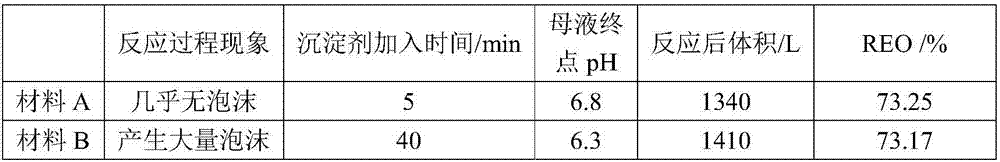

Image

Examples

Embodiment 1

[0015] Embodiment 1: mixed precipitant is the mixed solution of ammoniacal liquor and ammonium bicarbonate, and the mol ratio of ammoniacal liquor and ammonium bicarbonate is 1.38:1, and mixed precipitant temperature is 30 ℃, and total alkalinity is 3mol / L, takes this mixed precipitant Precipitating agent 736L. Pour cerium nitrate solution with a concentration of 1.0mol / L, pH=6.0, and a volume of 640L into a 3000L enamel reaction pot, turn on the reaction pot to stir, and heat to 90°C. Add the mixed precipitant according to the flow rate of 18.4L / min. During the reaction process, keep the reaction temperature at 90°C, and the feeding time is 40min. The amount of the mixed precipitant is 115% of the theoretical amount. The pH of the mother liquor end point is 7.4. Stop heating and continue stirring After 30 minutes, let it cool down to 40°C. Spin dry with a centrifuge, and rinse the precipitate with pure water at 30°C and a volume of 550 L to obtain basic cerium carbonate. Ba...

Embodiment 2

[0016] Embodiment 2: mixed precipitant is the mixed solution of ammoniacal liquor and ammonium bicarbonate, and the mol ratio of ammoniacal liquor and ammonium bicarbonate is 1.40:1, and mixed precipitant temperature is 25 ℃, and total alkalinity is 3.mol / L, takes The mixed precipitant 704L. Pour cerium nitrate solution with a concentration of 1.0mol / L, pH=6.0, and a volume of 640L into a 3000L enamel reaction pot, turn on the reaction pot to stir, and heat to 80°C. Add the mixed precipitant according to the flow rate of 17.6L / min. During the reaction process, keep the reaction temperature at 80°C, and the feeding time is 40min. The amount of the mixed precipitant is 110% of the theoretical amount. The pH of the mother liquor end point is 7.2. Stop heating and continue stirring After 30 minutes, let it cool down to 40°C. Spin dry with a centrifuge, and rinse the precipitate with pure water at 30°C and a volume of 550 L to obtain basic cerium carbonate. Basic cerium carbonate...

Embodiment 3

[0017] Embodiment 3: mixed precipitant is the mixed solution of ammoniacal liquor and ammonium bicarbonate, and the mol ratio of ammoniacal liquor and ammonium bicarbonate is 1.38:1, and mixed precipitant temperature is 25 ℃, and total alkalinity is 4mol / L, takes this mixed precipitant Precipitating agent 528L. Pour cerium nitrate solution with a concentration of 0.75mol / L, pH=6.0, and a volume of 853L into a 3000L enamel reaction pot, turn on the reaction pot to stir, and heat to 70°C. Add the mixed precipitant according to the flow rate of 10.6L / min. During the reaction process, keep the reaction temperature at 70°C, and the feeding time is 50min. The amount of the mixed precipitant is 110% of the theoretical amount. The pH of the mother liquor at the end point is 7.2. Stop heating and continue stirring After 30 minutes, let it cool down to 40°C. Spin dry with a centrifuge, and rinse the precipitate with pure water at 30°C and a volume of 550 L to obtain basic cerium carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com