Treatment and resource process for high-salt and high-COD wastewater produced from epichlorohydrin production using glycerol method

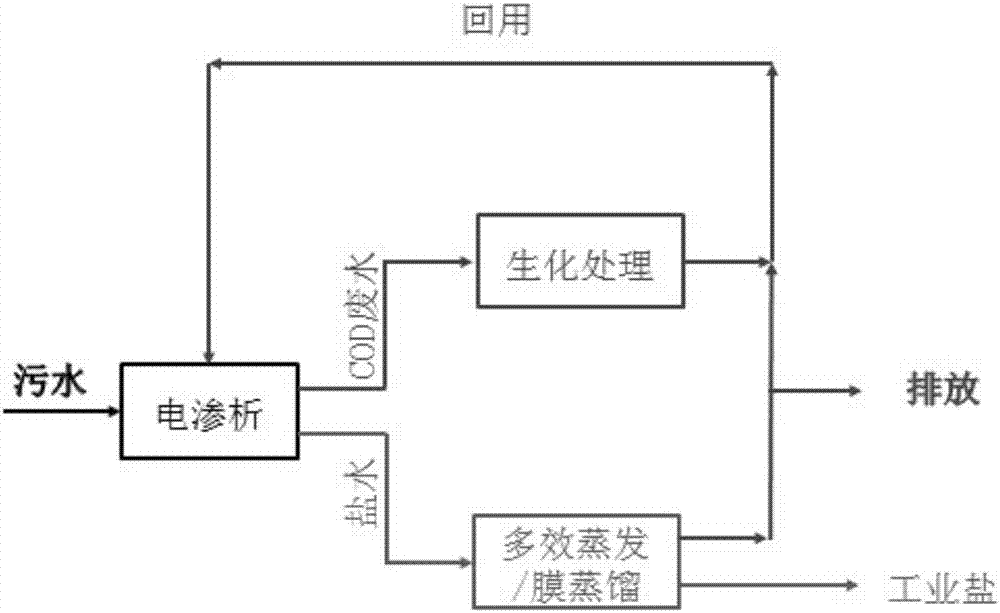

A technology of epichlorohydrin and high-salt wastewater, applied in the field of electrodialysis desalination, to achieve the effect of great application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

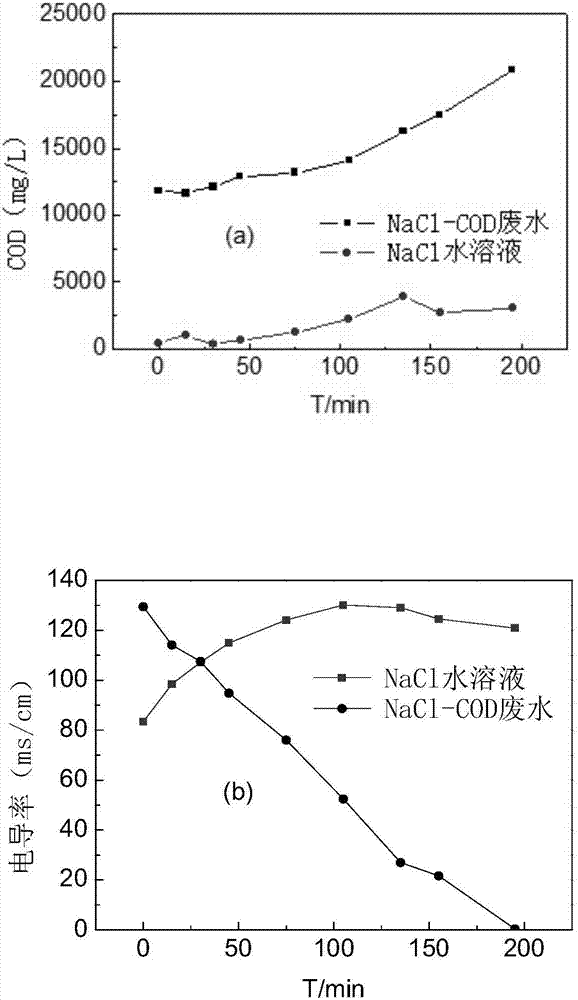

[0047] Epichlorohydrin wastewater comes from a certain factory, and its composition is: NaCl content 8.9wt.%, COD 11769mg / L, does not contain calcium, magnesium and other metal ions, pH=12.

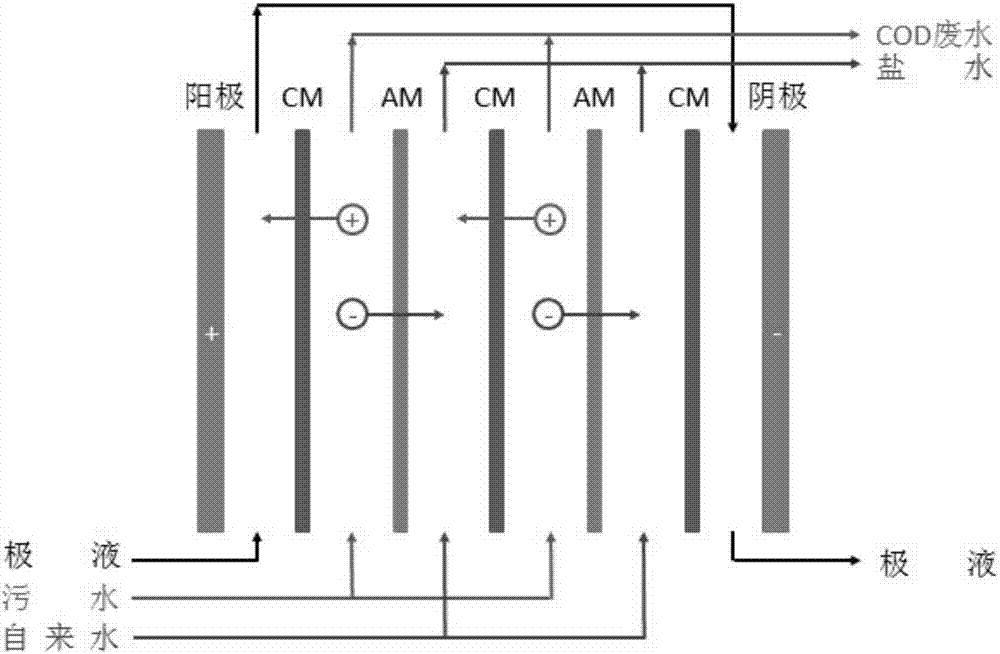

[0048] The electrodialyzer includes a pair of positive and negative plates, 200 anion-exchange membranes, 201 cation-exchange membranes, 2 separators between the ion-exchange membranes and the plates, and 400 flow channels between the anion-cation exchange membranes. The positive membrane is a sulfonic acid type homogeneous cation exchange membrane with a thickness of about 0.130mm and a resistance of 9.9Ω.cm 2 , the water content is 25%; the anion membrane is a quaternary ammonium type homogeneous anion exchange membrane, the thickness is about 0.150mm, and the resistance is 11.6Ω.cm 2 , the water content is 35%; the area of a single membrane is about 0.5m 2 . The thickness of the separator and flow channel is about 0.5mm, with 0.1M Na 2 SO 4 The solution is a polar liquid, a volta...

Embodiment 2

[0052] Epichlorohydrin wastewater comes from a factory, and its composition is: NaCl content 7.6wt.%, COD 14392mg / L, does not contain calcium, magnesium and other metal ions, pH=12.

[0053] The electrodialyzer includes a pair of positive and negative plates, 10 anion-exchange membranes, 11 cation-exchange membranes, 2 separators between the ion-exchange membranes and the plates, and 20 flow channels between the anion-cation exchange membranes. The positive membrane is a sulfonic acid type homogeneous cation exchange membrane with a thickness of about 0.130mm and a resistance of 9.9Ω.cm 2 , the water content is 25%; the anion membrane is a quaternary ammonium type homogeneous anion exchange membrane, the thickness is about 0.150mm, and the resistance is 11.6Ω.cm 2 , the water content is 35%; the area of a single membrane is about 0.03m 2 . The thickness of the separator and flow channel is about 0.5mm, with 0.1M Na 2 SO 4 The solution is a polar liquid, a voltage of 5.6V...

Embodiment 3

[0058] Epichlorohydrin wastewater comes from a factory and consists of: CaCl 2 Content 6.65wt.%, COD is 10903mg / L, does not contain calcium magnesium and other metal ions, pH=12.

[0059] The pH was adjusted below 7 by adding a small amount of HCl. The electrodialyzer includes a pair of positive and negative plates, 10 anion-exchange membranes, 11 cation-exchange membranes, 2 separators between the ion-exchange membranes and the plates, and 20 flow channels between the anion-cation exchange membranes. The positive membrane is a heterogeneous cation exchange membrane with a thickness of about 0.40mm and a resistance of 30Ω.cm 2 , the water content is 40%; the anion membrane is a quaternary ammonium type homogeneous anion exchange membrane, the thickness is about 0.45mm, and the resistance is 31.6Ω.cm 2 , the water content is 40%; the area of a single membrane is about 0.03m 2 . The thickness of the separator and flow channel is about 0.5mm, with 0.1M Na 2 SO 4 The solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com