Preparation method of deodorization type slow-release essential oil high-buffer and slow-rebound polyurethane soft foam

A soft foam and deodorizing technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as no deodorization performance, reduce non-penetrating damage, good absorption, and not easy to fall off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

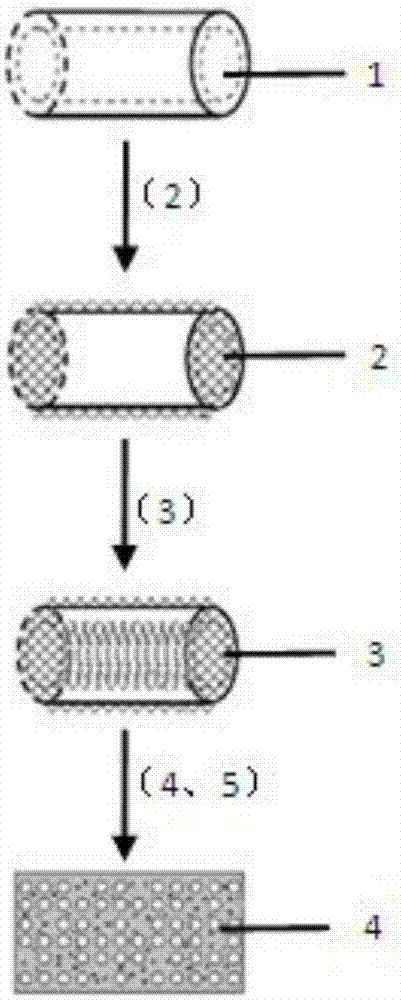

[0027] Such as figure 1 Shown, a kind of preparation method of deodorant type sustained-release essential oil high cushioning slow rebound polyurethane soft foam, it comprises following specific steps:

[0028] (1) Take halloysite nanotubes and soak them in dilute hydrochloric acid with a mass fraction of 5-20% at a temperature of 25-80°C for 30-60 minutes, then take them out for filtration, washing, After drying, the activated halloysite nanotubes are obtained;

[0029] (2) Take the cyclodextrin and under the protection of protective gas, dissolve the cyclodextrin in the solvent according to the weight ratio of the cyclodextrin to the solvent is 1:5-10 to obtain a cyclodextrin solution, and then press the activated angstrom The weight ratio of halloysite nanotubes to cyclodextrin is 1:3-10. The activated halloysite nanotubes prepared in step (1) are added to the cyclodextrin solution and mixed uniformly to obtain solution a, and then press the cyclodextrin The weight ratio ...

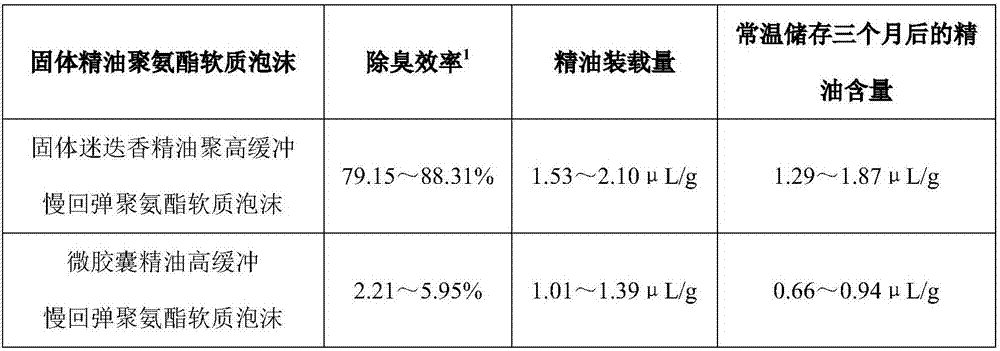

Embodiment 1

[0043] A kind of preparation method of deodorant type sustained-release essential oil high cushioning slow rebound polyurethane soft foam, it comprises the following steps:

[0044] (1) Immerse the halloysite nanotubes in dilute hydrochloric acid with a mass fraction of 20% at a temperature of 25° C. for 60 minutes, filter, wash, and dry in sequence to obtain activated halloysite nanotubes 1;

[0045] (2) Under nitrogen protection, according to the weight ratio of β-cyclodextrin and dimethyl sulfoxide 1:5, β-cyclodextrin was dissolved in dimethyl sulfoxide to obtain a β-cyclodextrin solution; Add the activated halloysite nanotube 1 obtained in step (1) to the β-cyclodextrin solution, the weight ratio of the activated halloysite nanotube to β-cyclodextrin is 1:10, and mix uniformly to obtain solution a; Add 2,4-toluene diisocyanate to solution a, the weight ratio of β-cyclodextrin to 2,4-toluene diisocyanate is 1:1, mix well to obtain solution b; heat solution b to a temperatur...

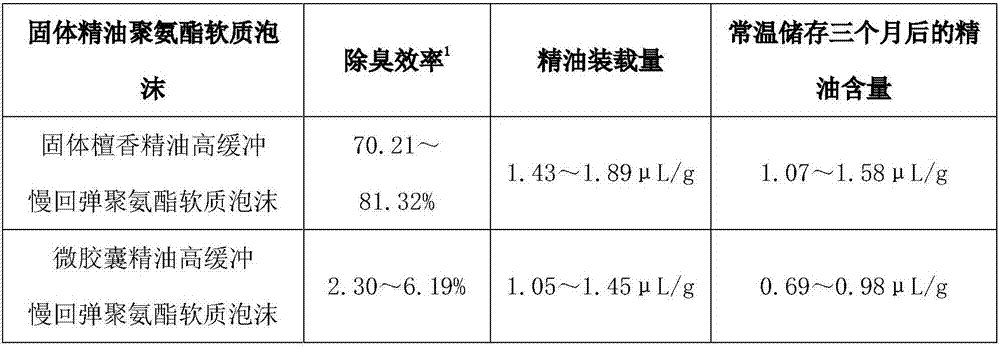

Embodiment 2

[0057] A kind of preparation method of deodorant type sustained-release essential oil high cushioning slow rebound polyurethane soft foam, described preparation method comprises the following steps:

[0058] (1) Dip the halloysite nanotubes in dilute hydrochloric acid with a mass fraction of 5% at a temperature of 80° C. for 30 minutes, filter, wash, and dry in sequence to obtain activated halloysite nanotubes 1;

[0059] (2) Under the protection of argon, dissolve hydroxypropyl β-cyclodextrin in dimethyl sulfoxide according to the weight ratio of hydroxypropyl β-cyclodextrin and dimethyl sulfoxide 1:10 to obtain hydroxypropyl β-cyclodextrin Propyl β-cyclodextrin solution; then add the activated halloysite nanotube 1 obtained in step (1) to the hydroxypropyl β-cyclodextrin solution, activate the halloysite nanotube and hydroxypropyl β-cyclodextrin The weight ratio of essence is 1:3, mix well to get solution a; then add 4,4-diphenylmethane diisocyanate, hydroxypropyl β-cyclodex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com