Micro-fluidic cell sorting chip and method coupled with dielectrophoresis and spatial isolation

A space separation and microfluidic technology, applied in the field of cell sorting, can solve the problems of large chip size, etc., and achieve the effect of solving the problem that the chip channel is too long and the dielectric difference of different cells is not obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

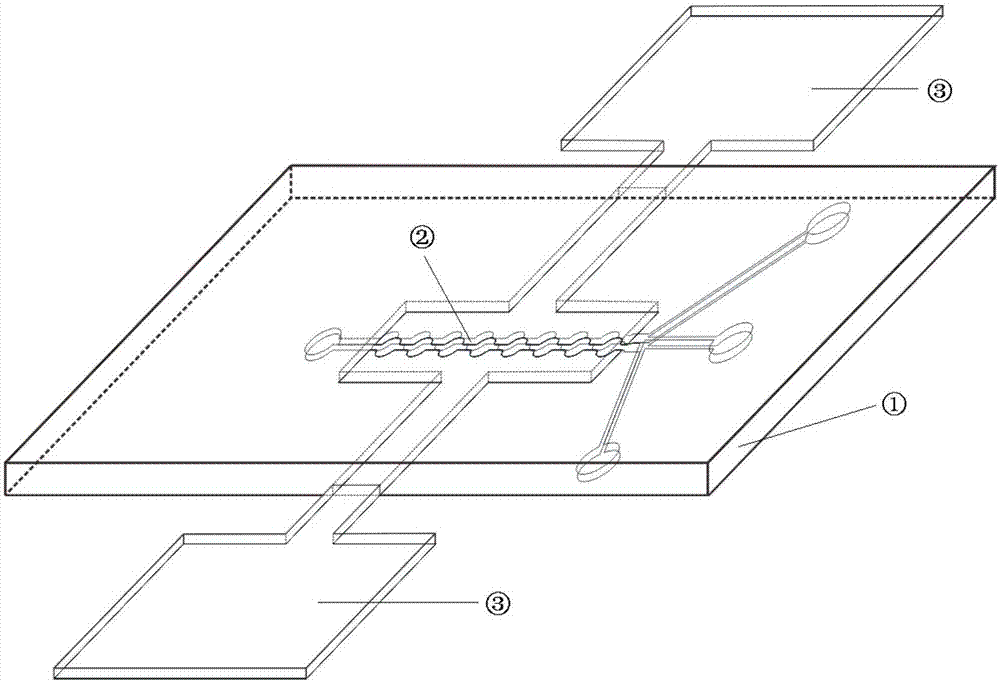

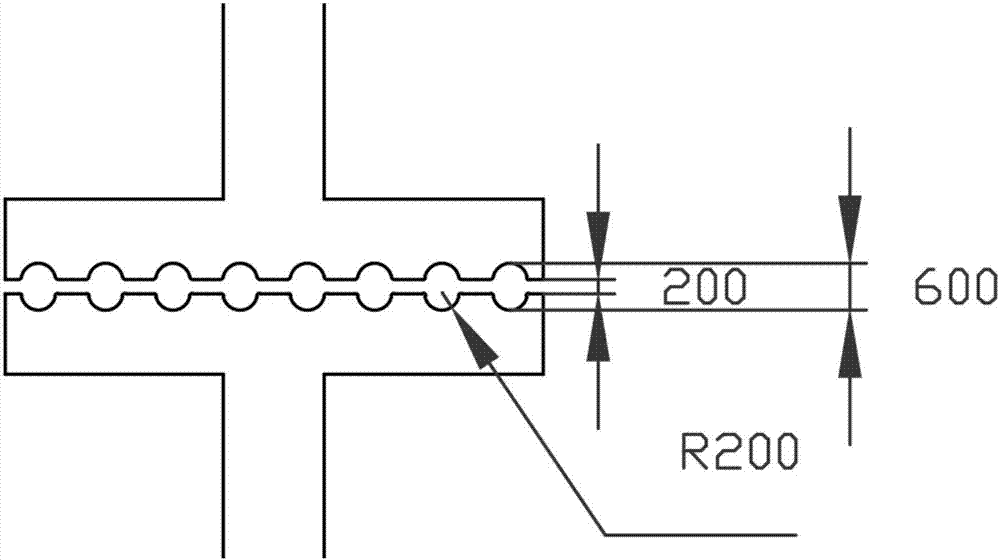

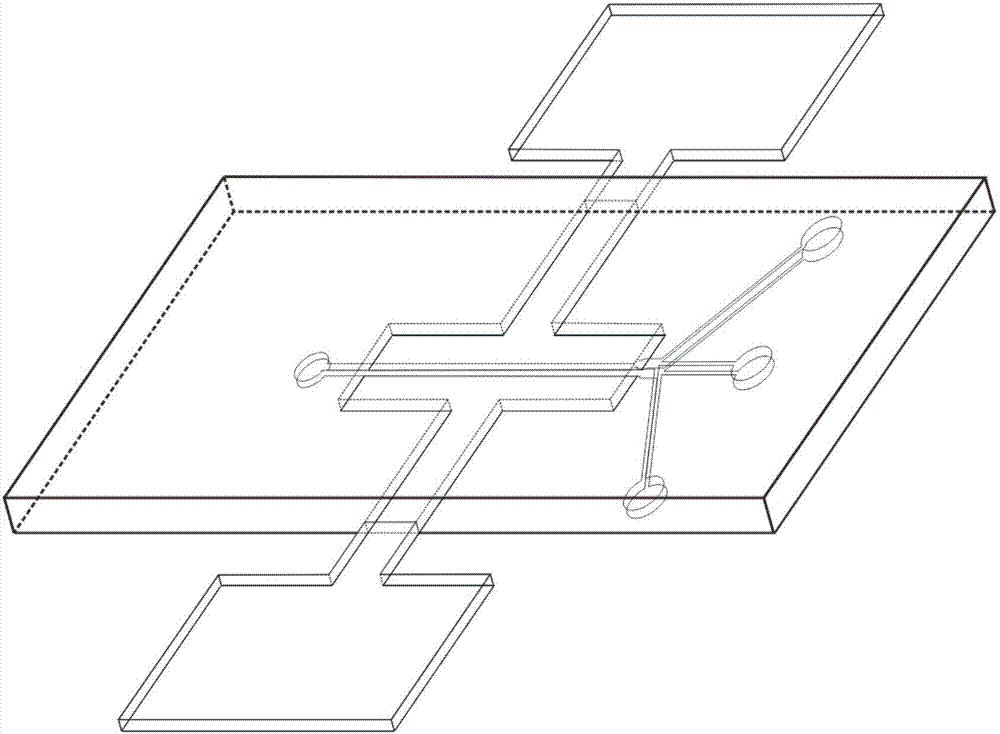

[0032] A microfluidic cell sorting chip coupled with dielectrophoresis and space separation in this embodiment, its structure schematic diagram is as follows figure 1 shown. It consists of a glass substrate ①, a main channel ② on the glass substrate and electrodes ③ on both sides of the main channel. The main channel contains 8 contraction and expansion structures, and one electrode with a thickness of 100 um is arranged on both sides of the main channel. The height of the main channel is 100um, the length is 8mm, the width of the shrinkage part of the channel is 200um and the width of the expansion part is 600um, and the shape of the expansion part on the side of the channel is a semicircle with a radius R of 200um. The schematic diagram of its structural size is as follows figure 2 shown.

[0033] The microfluidic cell sorting chip of this example was prepared by the following method:

[0034] Using conductive carbon ink as the material, microelectrodes (electrode thickn...

Embodiment 2

[0039] A microfluidic cell sorting chip coupled with dielectrophoresis and space separation in this embodiment is composed of a glass substrate, a main channel on the glass substrate, and electrodes on both sides of the main channel. The main channel contains 8 contraction and expansion structures, and one electrode with a thickness of 130um is arranged on both sides of the main channel. The length of the main channel is 8 mm, the height is 130 um, the width of the constricted part of the channel is 200 um and the width of the expanded part is 600 um, and the shape of the expanded part on one side of the channel is a semicircle with a radius of 200 um.

[0040] The microfluidic cell sorting chip of this example was prepared by the following method:

[0041] Using conductive carbon ink as the material, microelectrodes (electrode thickness 130um) were prepared on the float glass substrate by screen printing; using polydimethylsiloxane (PDMS) as the material, micro-machining (MEM...

Embodiment 3

[0046] A microfluidic cell sorting chip coupled with dielectrophoresis and space separation in this embodiment is composed of a glass substrate, a main channel on the glass substrate, and electrodes on both sides of the main channel. The main channel contains four contraction and expansion structures, and one electrode with a thickness of 150um is arranged on both sides of the main channel. The length of the main channel is 6 mm, the height is 150 um, the width of the constricted part of the channel is 200 um and the width of the expanded part is 600 um, and the shape of the expanded part on one side of the channel is a semicircle with a radius of 200 um.

[0047] The microfluidic cell sorting chip of this example was prepared by the following method:

[0048] Using conductive carbon ink as the material, microelectrodes (electrode thickness 150um) were prepared on the float glass substrate material by screen printing; using polydimethylsiloxane (PDMS) as the material, micro-ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com