An integrated process for coke oven flue gas desulfurization and denitrification

A technology for desulfurization, denitrification, and desulfurization catalyst, which is applied in the field of flue gas purification, can solve the problems of low flue gas temperature, high energy consumption, and cannot meet the temperature requirements of alum-based catalysts, and achieves simple regeneration process, long chemical life, and reduced investment. and the effect of running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

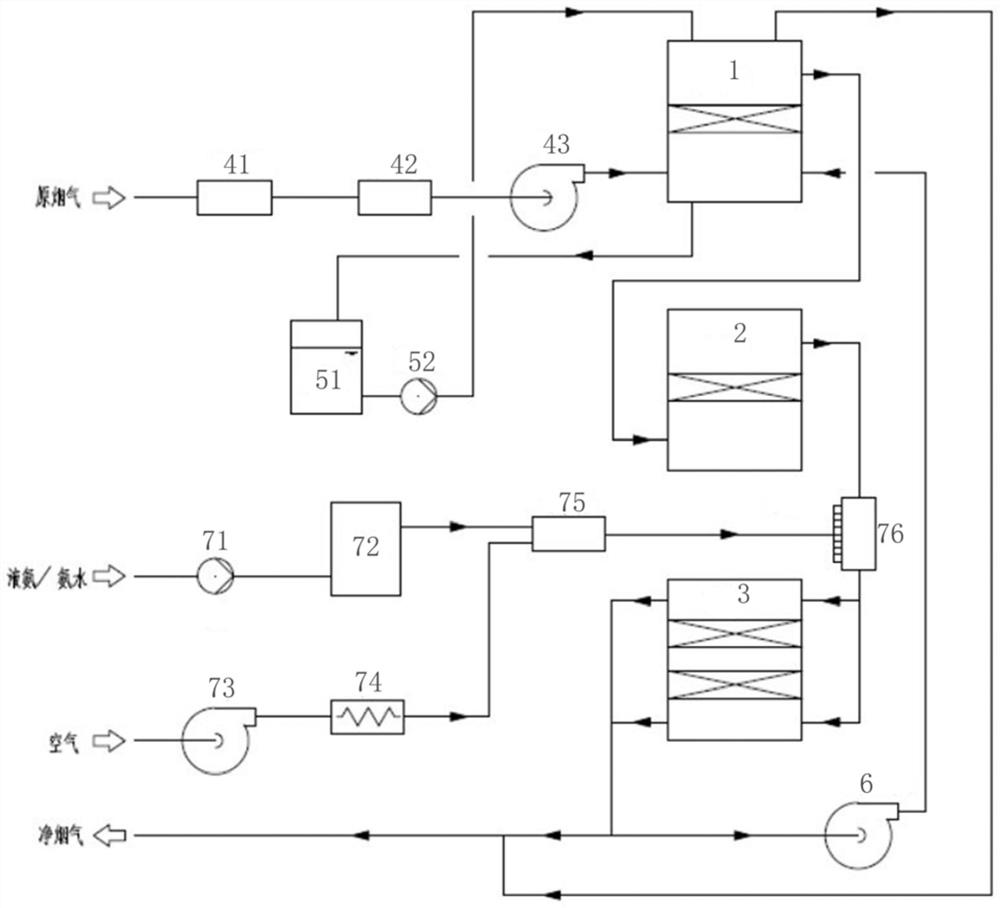

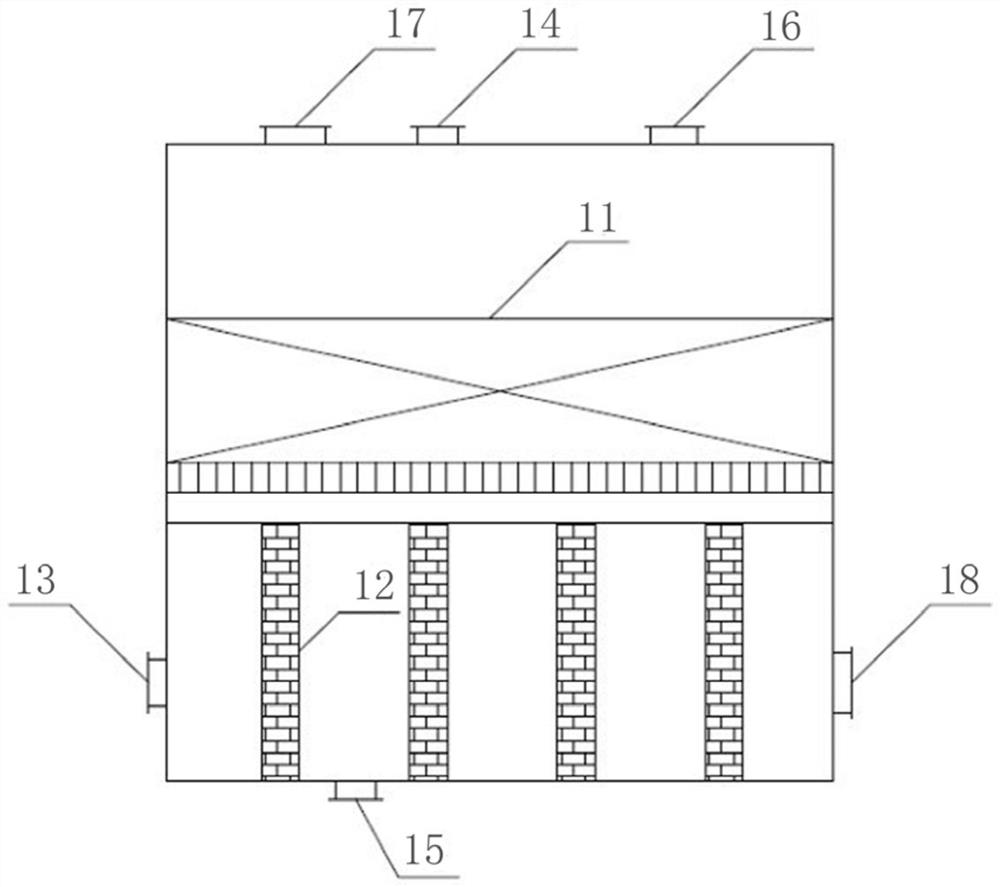

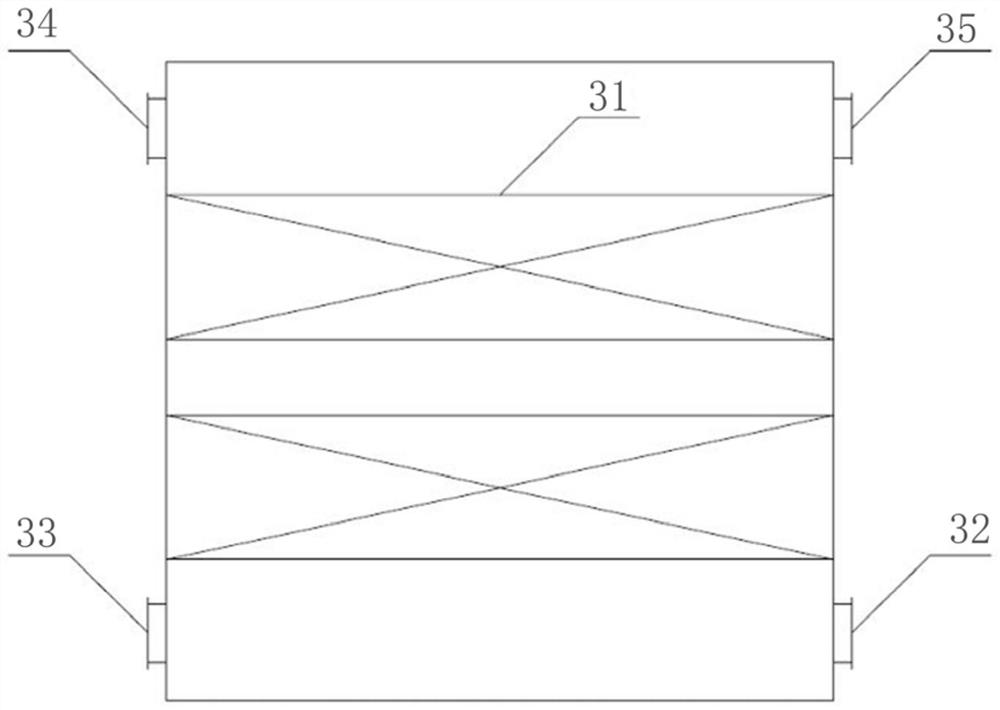

[0044] The coke oven flue gas desulfurization and denitrification integrated process of this embodiment relies on the following coke oven flue gas integrated desulfurization and denitrification system, such as Figure 1~3 As shown, the system includes a desulfurization system and a denitrification system. The desulfurization system includes a flue gas conditioning subsystem, a desulfurization tower 1, a washing subsystem, and a drying subsystem. The flue gas conditioning subsystem, the washing subsystem, and the drying subsystem are connected to each other through pipelines The desulfurization tower 1 is connected, and the flue gas conditioning subsystem adjusts the temperature and humidity of the coke oven flue gas to the set value before sending it to the desulfurization tower 1, and then discharges it after being desulfurized by the desulfurization catalyst in the desulfurization tower 1; the washing subsystem sends the aqueous solution to into the desulfurization tower 1 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com