Anti-freeze waterproof coating composition and preparation method thereof

A technology of composition and bentonite, which is applied in the field of building materials to achieve the effect of excellent waterproof performance and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In some embodiments of the present invention, the preparation method of described organobentonite comprises the steps of:

[0033] 1) Add 100 parts by weight of calcium-based bentonite and 300-500 parts by weight of water to make a pulp. The calcium-based bentonite is natural calcium-based bentonite, and then add hydrochloric acid. The amount of acid is 1.2-1.5 times the cation exchange capacity of bentonite. For more than an hour, press filter and dehydrate to obtain acid-activated bentonite;

[0034] 2) Beat the acid-activated bentonite, the concentration of the bentonite slurry in the sodiumization process is 10-15wt%, add sodium oxalate and sodium citrate, the amount is 1.2-1.5 times the cation exchange capacity of bentonite, heat and stir, and react 0.5-1.5 h, centrifuging to remove impurities to obtain a sodium bentonite suspension;

[0035] 3) Heat the sodium-based bentonite suspension to 70-80°C, add an organic modifier under stirring conditions, stir, react fo...

Embodiment 2

[0063] An antifreeze and waterproof smear composition, comprising 30 parts of cinder, 30 parts of organic bentonite obtained in Example 1, 2 parts of hydroxymethyl cellulose, and 2 parts of glycidyl ester epoxy resin.

[0064] The preparation method of above-mentioned a kind of antifreeze waterproof smear composition, comprises the steps:

[0065] S1, after mixing 30 parts of cinder, 30 parts of organic bentonite, 2 parts of hydroxymethyl cellulose and 2 parts of glycidyl ester epoxy resin, grind them, and pass through a 40-mesh sieve;

[0066] S2. Add the ground cinder, organic bentonite, hydroxymethyl cellulose and epoxy resin into the reaction tank, add 50 parts of water, heat to 50°C and stir evenly to form a slurry of antifreeze and waterproof coating composition.

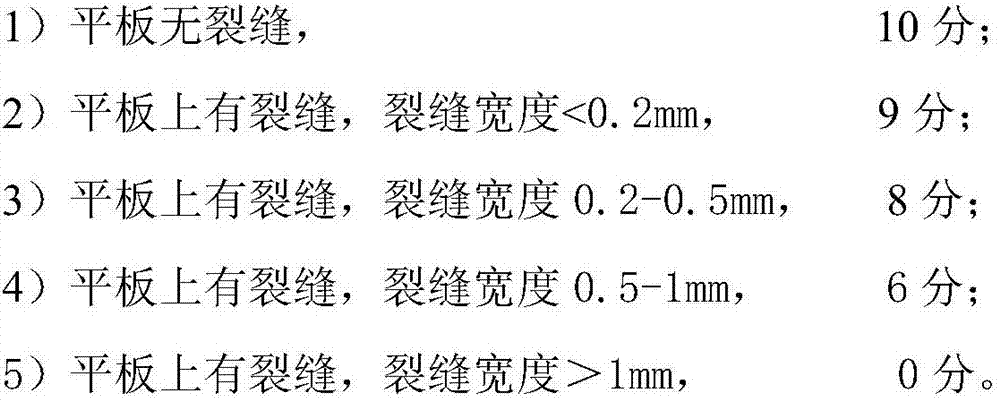

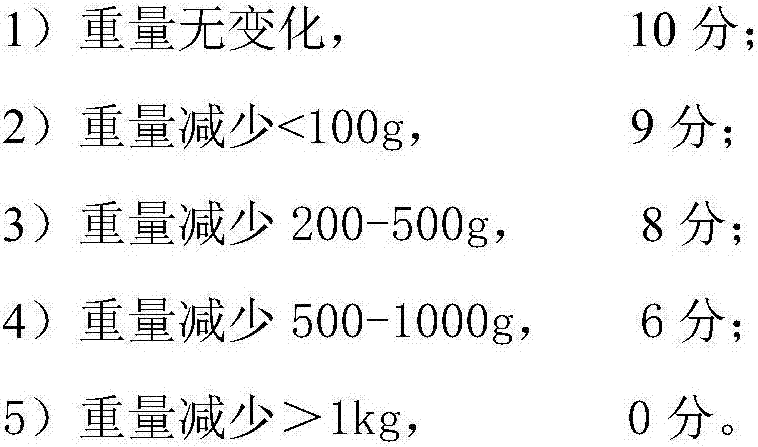

[0067] After testing, the antifreeze and waterproof smear composition of this embodiment has 10 points for antifreeze performance and 10 points for waterproof performance at -20°C; 9 points for antifreeze perf...

Embodiment 3

[0069] An antifreeze and waterproof smear composition, comprising 50 parts of cinder, 50 parts of organic bentonite obtained in Example 1, 5 parts of hydroxypropyl cellulose, and 5 parts of glycidyl ester epoxy resin.

[0070] The preparation method of above-mentioned a kind of antifreeze waterproof smear composition, comprises the steps:

[0071] S1. Grinding after mixing 50 parts of cinder, 50 parts of organic bentonite, 5 parts of hydroxypropyl cellulose and 5 parts of glycidyl ester epoxy resin, passing through a 60-mesh sieve;

[0072] S2. Add the ground cinder, organic bentonite, hydroxypropyl cellulose and epoxy resin into the reaction tank, add 80 parts of water, and stir to form a uniform slurry.

[0073] After testing, the antifreeze and waterproof smear composition of this embodiment has 10 points for antifreeze performance and 10 points for waterproof performance at -20°C; 9 points for antifreeze performance and 9 points for waterproof performance at -30°C; 9 poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com