Corrosion-resistant heat-conducting pipeline for conveying heat-conducting medium

A heat-conducting medium and corrosion-resistant technology, applied in the field of polymer materials, can solve the problems of sacrificial polymer material insulation performance, mechanical performance and processing performance, achieve good contact and interaction, reduce thermal resistance, and improve wear resistance and impact strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

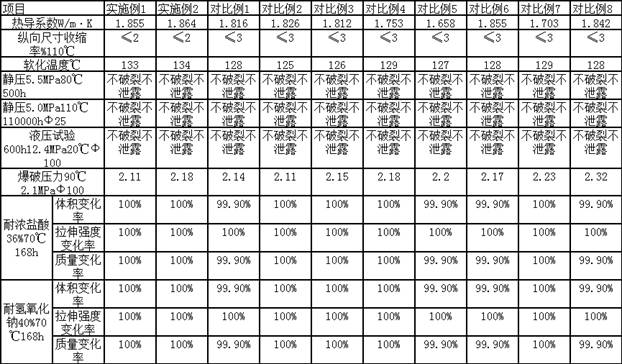

Examples

Embodiment 1

[0021] A corrosion-resistant and heat-conducting pipe for transporting heat-conducting media, made of the following raw materials in parts by weight: 96 parts of high-density polyethylene, 23 parts of polybutylene terephthalate, 5 parts of ethylene-vinyl acetate, and 5 parts of polycaprolactam 4 parts, 4 parts of chlorinated polyethylene, 1.3 parts of fluorine-containing lubricant, 5 parts of nano-tin antimony oxide, 9 parts of expanded graphite fiber, 15 parts of thermal conductive fiber, 8 parts of mica powder, 4 parts of transition metal composite oxide, light stable 0.5 parts of lithium-based bentonite, 17 parts of polyaniline, 1.5 parts of magnesium oxide powder, and 1 part of silicon carbide powder; the thermal conductive fiber wire is composed of metal fiber wire and inorganic fiber wire in a mass ratio of 2:1, and the metal fiber wire The wire is tungsten fiber, stainless steel fiber.

[0022] Further, the fluorine-containing lubricant is ethylene-tetrafluoroethylene-d...

Embodiment 2

[0032] A corrosion-resistant heat-conducting pipe for transporting heat-conducting media, made of the following raw materials in parts by weight: 85 parts of high-density polyethylene, 15 parts of polybutylene terephthalate, 3 parts of ethylene-vinyl acetate, and 2 parts of polycaprolactam 2 parts, 2 parts of chlorinated polyethylene, 1.3 parts of fluorine-containing lubricant, 5 parts of nano-antimony tin oxide, 9 parts of expanded graphite fiber, 15 parts of thermally conductive fiber, 8 parts of mica powder, 4 parts of transition metal composite oxide, light stable 0.5 parts of lithium bentonite, 0.5 parts of lithium-based bentonite, 12 parts of polyaniline, 1 part of magnesium oxide powder, and 0.5 parts of silicon carbide powder; the thermal conductive fiber wire is composed of metal fiber wire and inorganic fiber wire in a mass ratio of 2:1, and the metal fiber wire The wire is tungsten fiber, stainless steel fiber.

[0033] Further, the fluorine-containing lubricant is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com