Nano calcium carbonate modified by polyether carboxylate, sealant comprising nano calcium carbonate and preparation method of sealant

A technology of nano-calcium carbonate and polyether carboxylate, which is applied in the field of sealants, can solve problems such as uneven dispersion of nano-calcium carbonate, and achieve the effects of easy operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

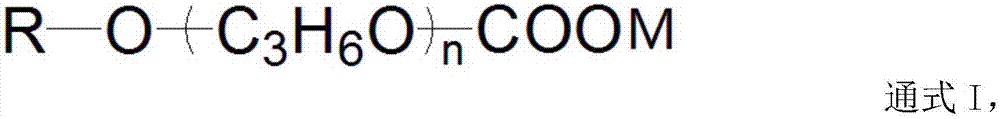

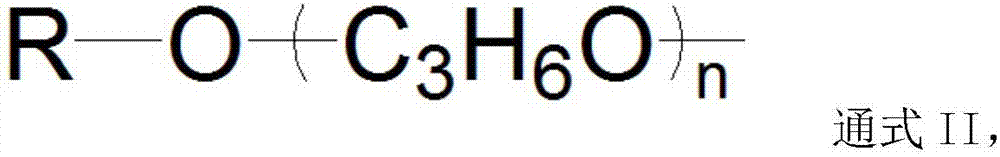

[0043] The invention provides a preparation method of polyether carboxylate, the number average molecular weight of the modified polyether is 333-1313g / mol, and its structure is shown in the following general formula I:

[0044]

[0045] Among them, R is straight chain or branched C 6 -C 18 The alkyl group, n=4-18, n is an integer.

[0046] In the present invention, the R is preferably a linear or branched C 6 -C 18 Alkyl, preferably branched C 8 -C 15 Alkyl, preferably branched C 8Alkyl, branched C 10 Alkyl or branched C 13 of alkyl. In a specific embodiment of the present invention, the branched C 8 The alkyl group of is preferably the alkyl moiety of 6-methyl-1-heptanol. The branched C 10 The alkyl group is preferably EXXAL TM The alkyl moiety of 10. The branched C 13 The alkyl group is preferably EXXAL TM The alkyl moiety of 13. Wherein, the 6-methyl-1-heptanol (CAS No. 26952-21-6) and the EXXAL TM 8 (CAS No. 68526-83-0) are all isooctyl alcohols. The ...

Embodiment 1

[0092] In the present embodiment, the nano-calcium carbonate modified by polycarboxylate is prepared by the following method, and the method steps are as follows:

[0093] (1) Material preparation: Weigh 20g of nano-calcium carbonate, add it to a three-necked flask, then add 80ml of water to form a suspension, keep at 80°C and stir;

[0094] (2) Add polyether carboxylate into a three-necked flask, and stir for 1 h;

[0095] (3) Vacuum suction filtration while hot with a Buchner funnel;

[0096] (4) Transfer the product to a clean crucible and place it at 115°C for drying;

[0097] (5) Grinding the dried material is modified nano-calcium carbonate.

[0098] The structure of the polyether carboxylate used in the present embodiment is shown in following general formula I:

[0099]

[0100] Wherein, R is n-octyl, n is 9, and M is Na.

Embodiment 2-4

[0102] Examples 2-4 relate to the preparation of a sealant containing polyether carboxylate-modified nano-calcium carbonate prepared according to Example 1.

[0103] The sealant in embodiment 2-4 is prepared by following method, and this method step is as follows:

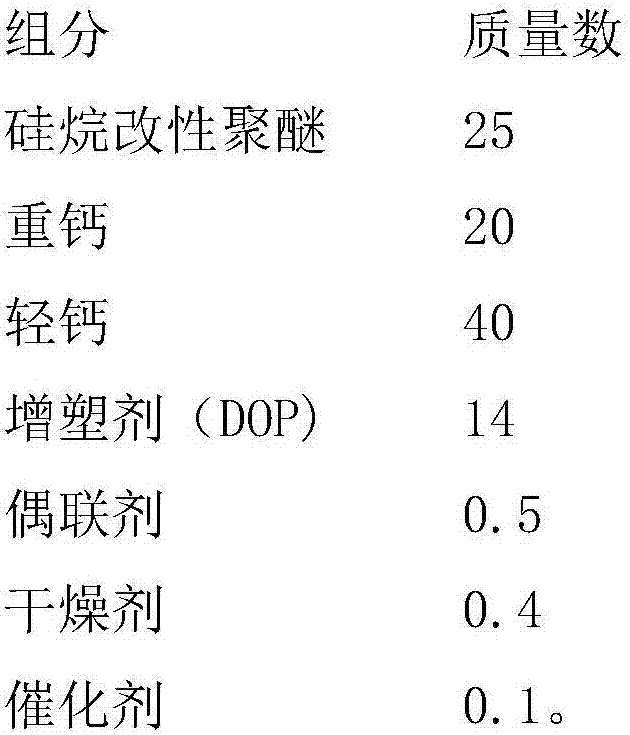

[0104] (1) Prepare materials: prepare materials according to the mass percentage of silane modified polyether sealant;

[0105] (2) Use double planetary mixer for mixed production: put light calcium, heavy calcium, silane modified polyether resin, coupling agent, plasticizer and accelerator into the material tank, and stir evenly;

[0106] (3) Add light stabilizer, stir at high speed until the dispersion is uniform, and there are no particles in the material;

[0107] (4) be heated up to 100-150 ℃, vacuumize and keep warm for 1-3 hours;

[0108] (5) Cool down to 30-60°C and stop the vacuum;

[0109] (6) Add the catalyst, stir evenly, and degas the glue.

[0110] Silane-modified polyether sealant, the sealant in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap