Anti-infrared-monitoring waterproof and flame-retardant polyamide fiber fabric preparation process

A flame-retardant polyamide and fiber fabric technology, applied in the field of textile manufacturing, can solve the problem of finding no flame-retardant dyeing and finishing methods, and achieve the effects of increasing the adhesion firmness, improving the waterproof performance, and improving the adhesion firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

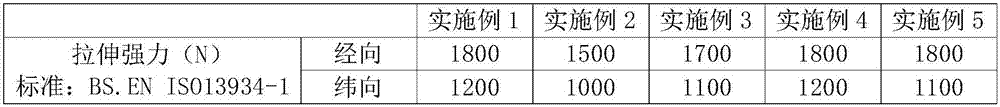

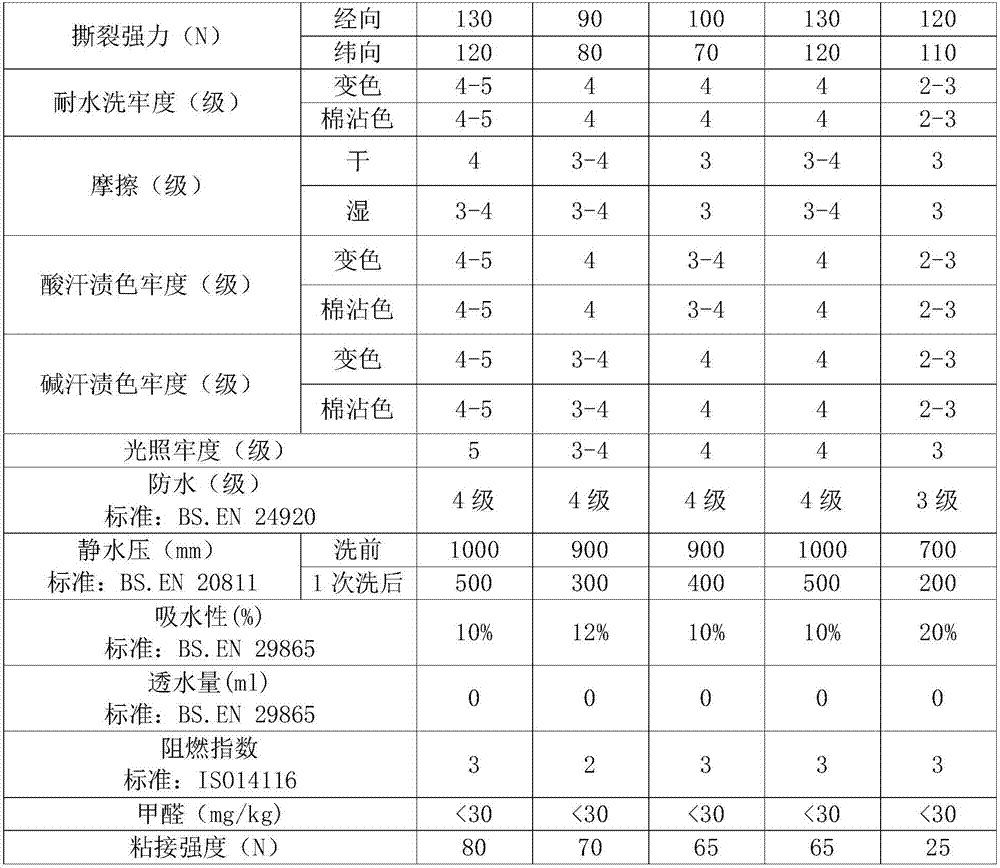

Examples

Embodiment 1

[0032] A preparation process of a waterproof and flame-retardant polyamide fiber fabric that is protected against infrared monitoring, and its specific preparation process includes: gray cloth→cloth turning→cold pad-batch→scouring→setting→dyeing bottom→printing→baking→steaming→soap Washing→color fixing treatment→waterproof tenter→calendering→back glued tenter→calendering→inspection→finished product.

[0033] Among them, the parameters in each step are set as follows:

[0034] During cold pad-batch treatment, use 40g / L caustic soda and 8g / L hydrogen peroxide to pad the gray cloth. After padding, roll and stack it for 12 hours. The gray cloth is a thick sparse fabric above 1000D.

[0035] When scouring, first carry out immersion, and then carry out steaming. Among them, the immersion method is five immersion and five rolling, the liquid carrying rate is 80%, and the tension of the washing machine is set to 4Mpa; the auxiliary agents for immersion include desizing and refining a...

Embodiment 2

[0049] The difference between this example and Example 1 is that no steaming operation is performed in step (2) in this example, and the weight of the substance added to the flame-retardant glue TF-680B in step (4) is different. The specific settings are as follows:

[0050] The process of gluing the tenter on the reverse side is as follows: the gluing operation is carried out with a coating scraper, the glue is flame-retardant glue TF-680B, and 0.3% of paint yellow G-24, 0.05% of Paint blue G-31, 0.2% paint black G-51, 3% smooth resin TF-399, 3% crosslinking agent TF-694B, 1% thickener DM-5299.

Embodiment 3

[0052] The difference between this embodiment and embodiment 1 is that the operating parameters of the scraper in step (4) in this embodiment are different, and the specific settings are as follows:

[0053] In this embodiment, the viscosity of the glue is 140cps, the temperature is 130-140°C, and the parameters of the coating scraper for thick and sparse fabrics above 1000D are: scraper thickness 2mm, blade distance 6mm, pressing distance 2mm, tension pressure 0.6Kpa , The speed is 30 m / min; the parameters of the coating scraper for other tight fabrics are: scraper thickness 1mm, blade distance 4mm, pressing distance 4mm, tension pressure 0.7Kpa, speed 40m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com