Pressure flow parameter experiment testing device of oil spraying component

A test and pressure technology, applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problems of oil mist drift, environmental pollution, safety hazards, etc., to avoid oil mist overflow, maintenance Simple maintenance, convenient operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings:

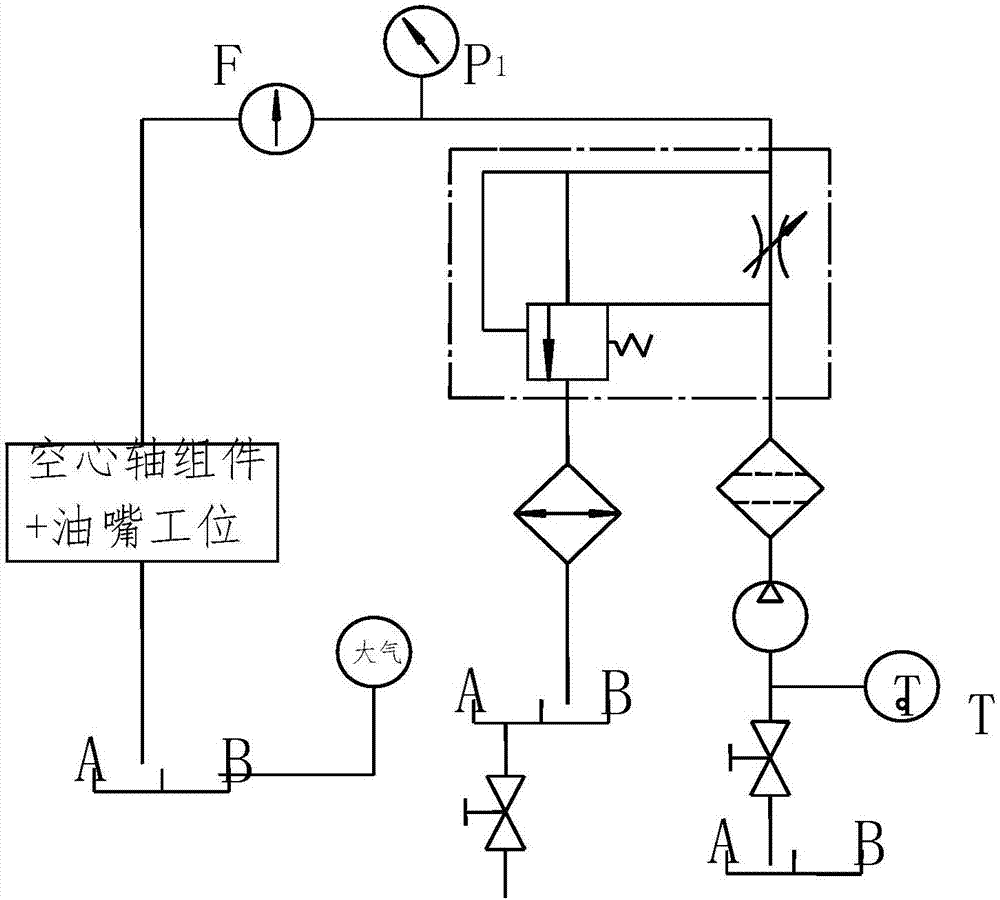

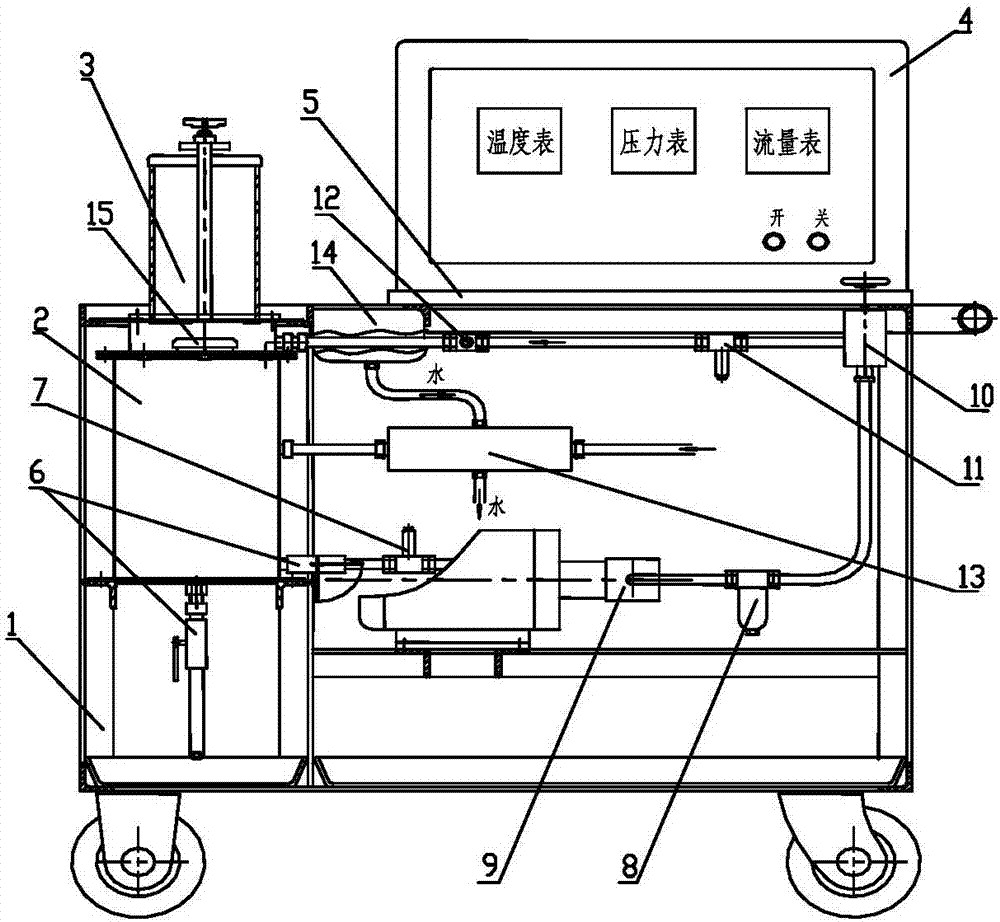

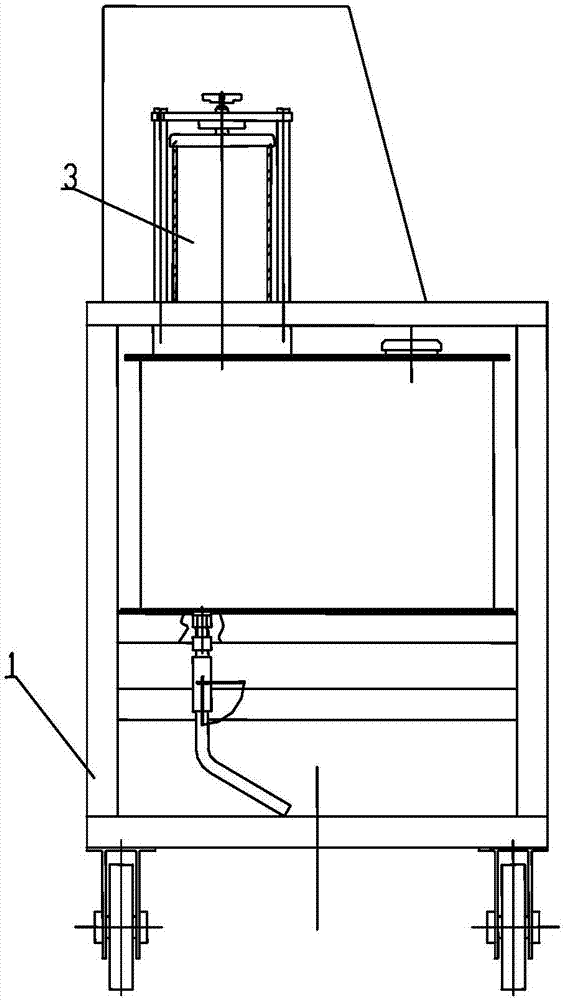

[0016] Such as Figure 1-Figure 3 Shown, a fuel injection component pressure and flow parameter test device, fuel tank 2, station assembly 3, power supply and instrument box 4, platen 5, ball valve 6, temperature sensor 7, lubricating oil filter 8, electric motor and oil pump 9 , Low pressure relief valve 10, pressure sensor 11, flow meter 12, air filter 15; oil tank 2, ball valve 6, temperature sensor 7 are connected through stainless steel pipes, connected to the inlet of oil pump 9, and then the outlet of oil pump 9 is connected to lubricating oil The oil filter 8 enters the inlet of the low pressure relief valve 10, and then two oil pipes are separated from the overflow valve 10, one is a pressure oil pipe, which connects the pressure sensor 11 and the flow meter 12, and leads to the station assembly 3 of the test device, The lower part of the station assembly is directly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com