Static protection structure in monolithic microwave integrated circuit and manufacturing method of static protection structure

A microwave integrated circuit and electrostatic protection technology, which is applied in the direction of circuit, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of limited integrated circuit layout area, large integrated circuit area, waste, etc., and achieve the effect of saving layout area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

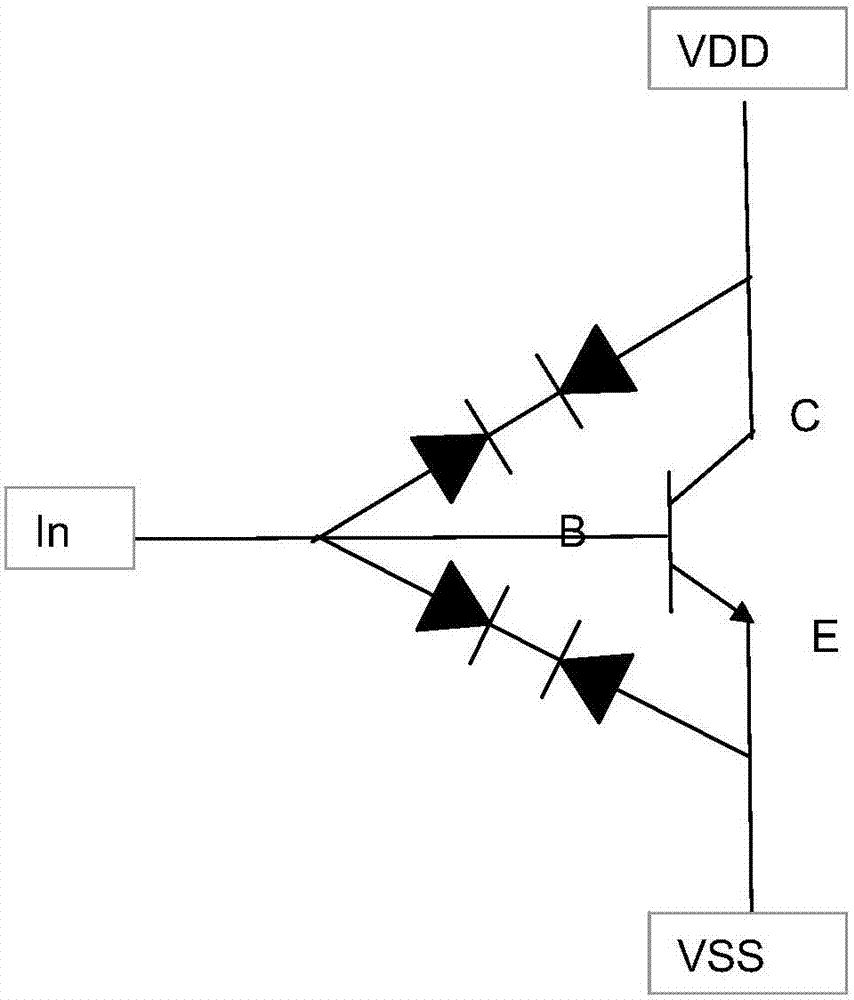

[0032] refer to figure 1 , the present embodiment provides an electrostatic protection structure in a monolithic microwave integrated circuit, in which diode groups arranged in a back-to-back structure are respectively arranged in parallel between the base region-the emitter region and the base region-the collector region of the HBT tube; each The diode group includes two diodes, and the anodes of the two diodes are connected to each other to form a back-to-back structure

[0033] When the chip is electrostatically discharged, the base area of the HBT tube and the substrate form a large voltage difference, which will break down the base area of the HBT tube. Therefore, add two reverse diodes connected in series near the base region and emitter region, base region and collector region. When electrostatic discharge occurs, no matter how the current flows, one of the two diodes will always conduct, so that The voltage difference between the base region and the substrate is c...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that: the diode group includes two diodes, and the cathodes of the two diodes are connected to each other to form a back-to-back structure. The rest is the same as that of Embodiment 1, and the working principle is also consistent with that of Embodiment 1, so it will not be repeated here.

Embodiment 3

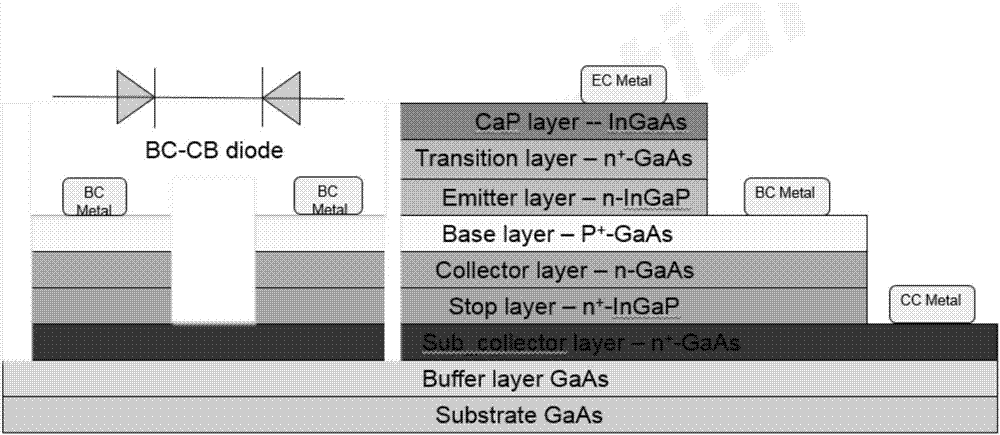

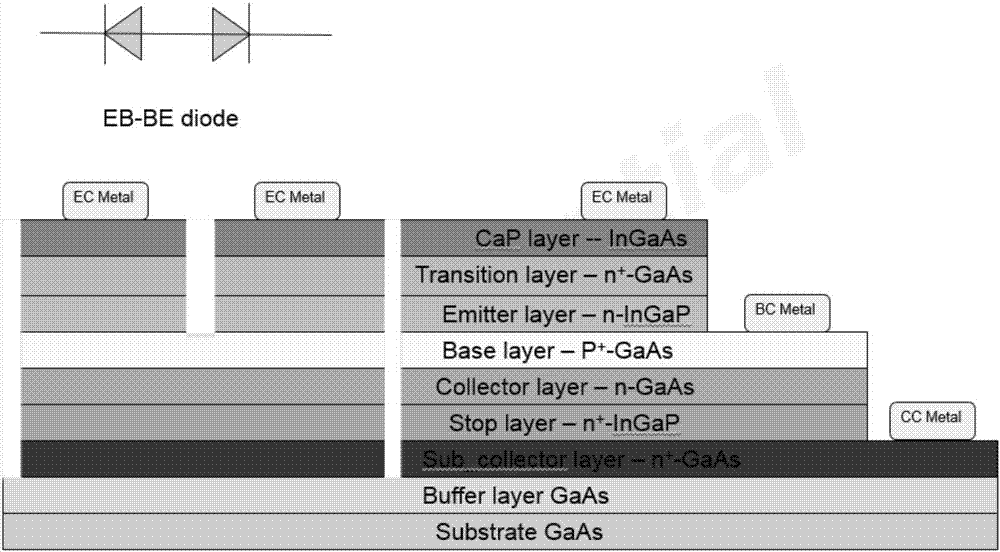

[0037] refer to figure 2 , the present embodiment provides a microstructure for electrostatic protection in a monolithic microwave integrated circuit, including at least one HBT tube prepared on a GaAs-based epitaxial wafer, and two diodes independent of the HBT tube are prepared on the GaAs-based epitaxial wafer ; Two diodes share a barrier n + -InGaP, and the two diodes are sequentially stacked on the barrier layer n + - Collector layer n-GaAs on InGaP, base layer p + -GaAs and emitter layer n + -GaAs; the collector layer n-GaAs of the two diodes to each other, the base layer p + -GaAs and emitter layer n + -GaAs are arranged independently of each other to form a back-to-back diode group with interconnected cathodes;

[0038] The anode BC Metal of one of the diodes is connected to the base area BC Metal of the HBT tube, and the anode BC Metal of the other diode is connected to the collector area CC Metal of the HBT tube; or, the anode BC Metal of one of the diodes is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com