Horizontal lead carbon battery and preparation method thereof

A lead-carbon battery, horizontal technology, used in the field of chemical power-related materials, can solve the problems of inability to adapt to high rate charge and discharge, long life requirements, electrolyte concentration polarization, low battery charge and discharge rate performance, etc. The effect of improving high-rate charge and discharge performance, easy operation, and simple and convenient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

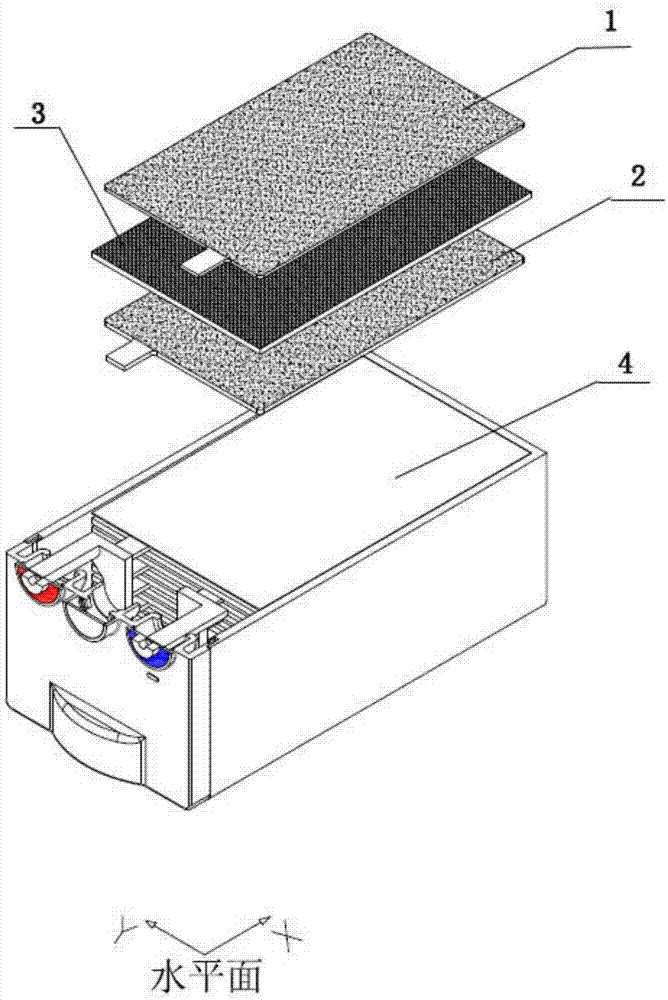

[0061] The invention also discloses a preparation method of a horizontal lead-carbon battery, comprising the following steps:

[0062] 1), weigh each component according to the negative electrode active material, mix each component uniformly, and prepare the negative electrode active material; weigh each component according to the carbon material grid, and prepare the carbon material grid;

[0063] 2), apply the negative electrode active material obtained in step 1) on the surface of the carbon material grid, and obtain a negative plate through solidification and drying;

[0064] 3), the negative plate (1) obtained in step 2), the positive plate (2) and the separator (3) are assembled into the battery cell (4), and the negative plate (1), positive plate (2) and The separators (3) are all arranged horizontally to obtain a horizontal lead-carbon battery.

[0065] Wherein, the preparation method of the carbon material grid comprises the following steps:

[0066] 1. Weighing the...

Embodiment 1

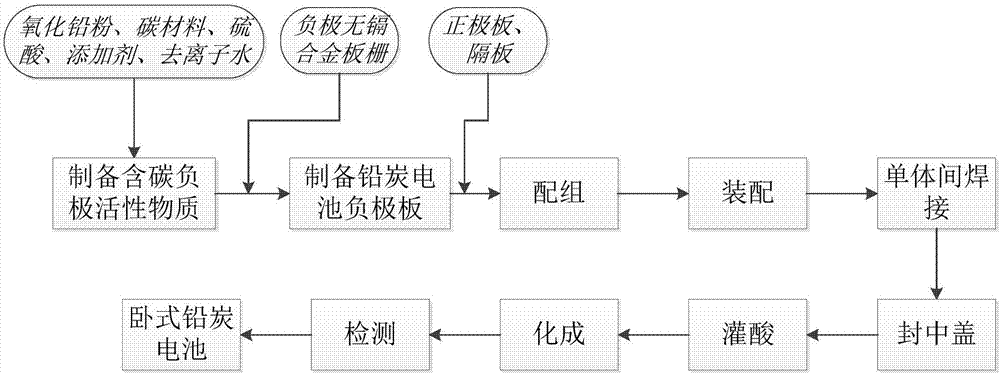

[0083] refer to figure 1 As shown, firstly, produce the lead-carbon battery negative plate with a nominal name of 48V5Ah, draw product-related drawings, and confirm the work documents, then implement the following work steps:

[0084] 1) According to lead oxide powder 60%, flying graphite 0.5%, porous carbon particles 1%, high specific surface area activated carbon 0.5%, conductive graphite 1%, carbon black 1%, acetylene black 1%, sulfuric acid 6%, additive 1%, The ratio of 28% deionized water is mixed evenly to prepare the carbon-containing active material used in the battery negative plate (1);

[0085] 2) coating the negative electrode carbon-containing active material on the surface of an alloy grid that does not contain cadmium elements, and curing and drying to obtain the negative electrode plate (1) of the negative electrode plate of the lead-carbon battery;

[0086] 3) Negative plate of lead-carbon battery After the negative plate (1) is matched with the positive plat...

Embodiment 2

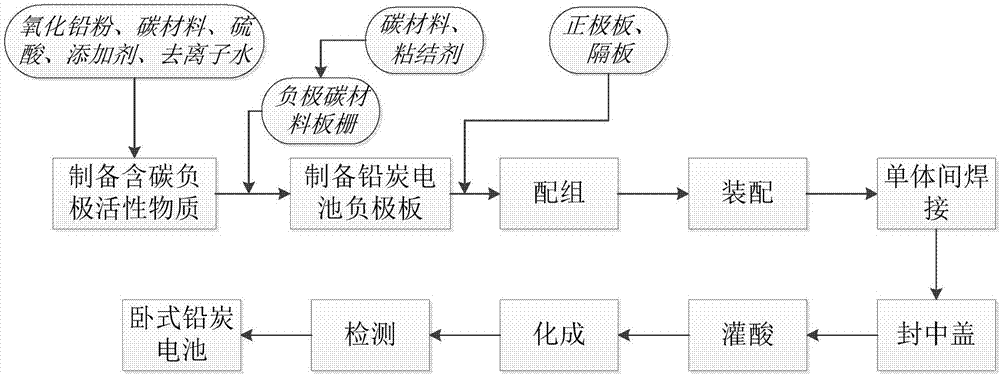

[0093] refer to figure 2 As shown, first of all, produce the lead-carbon battery negative plate with the nominal name of 2V4000Ah, draw the relevant drawings of the product, and confirm the operation documents, then implement the following work steps:

[0094] 1) According to 5% of flying graphite, 15% of porous carbon particles, 25% of high specific surface area activated carbon, 10% of conductive graphite, 5% of carbon black, 5% of acetylene black, 8% of sulfuric acid, 5% of additives, and 22% of deionized water The carbon-containing active material used for preparing the battery negative plate (1) is uniformly mixed in proportion;

[0095] 2) Carbon material grids are prepared according to the proportion of flying graphite 3%, full carbon airgel 5%, foam carbon 80%, conductive graphite 2%, carbon black 4%, acetylene black 1%, and binder 5%;

[0096] 3) coating the negative electrode carbon-containing active material on the surface of the carbon material grid, curing and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com