Low-viscosity liquid foundation and preparation method thereof

A liquid foundation and low-viscosity technology, which is applied in the preparation of low-viscosity liquid foundation and in the field of low-viscosity liquid foundation, can solve problems such as difficult stability of the system, and achieve uniform concealer, light and moist skin feeling, and strong makeup effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

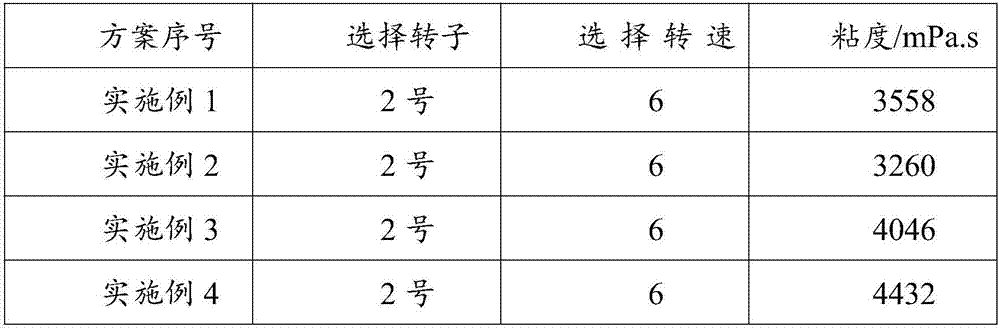

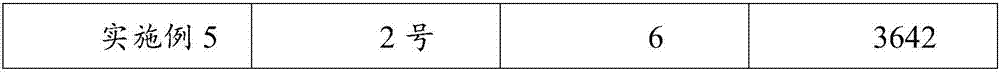

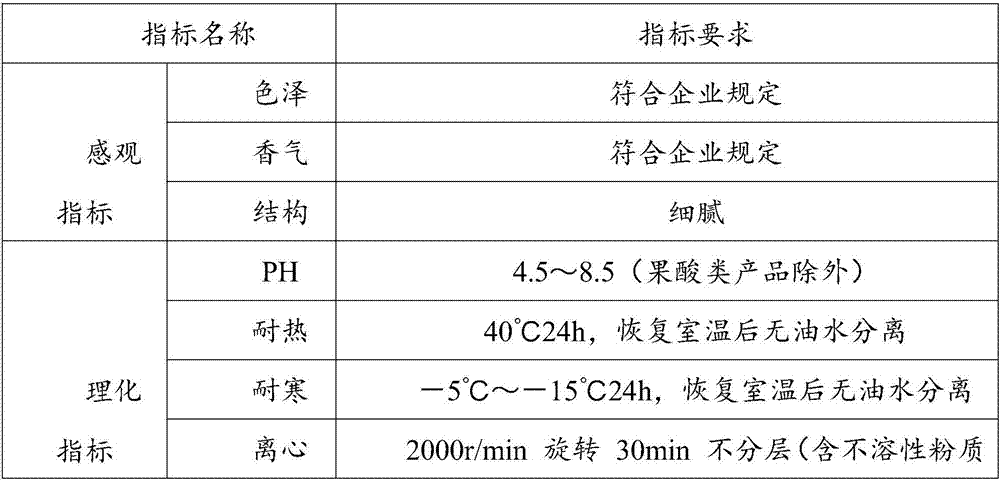

Examples

Embodiment 1

[0048] A low-viscosity liquid foundation provided by the present invention is made of A-phase components, B-phase components, C-phase components and D-phase components: based on 100 g of the total mass of the foundation liquid,

[0049] The components of phase A and their contents are as follows: 1.0 g of distearyldimethylammonium hectorite, 2.0 g of polydimethylsiloxane / vinyl polydimethylsiloxane crosslinked polymer , propylene carbonate 2.0g, lauryl PEG-10 tris(trimethylsiloxy) silylethyl methicone 1.2g, polyglyceryl-2 dipolyhydroxystearate 1.5g, PEG / PPG -18 / 18 Dimethicone 0.5g, Isohexadecane 8.0g, Isopropyl Myristate 2.0g, Dimethicone 3.0g, Dimethiconol 1.0g , caprylic / capric triglyceride 6.0g, tocopheryl acetate 1.3g, titanium dioxide 10.0g; iron oxide color powder 0.5g; magnesium stearate 1.5g;

[0050] The various substances and contents of the B-phase components are as follows: 5.0 g of glycerin, 10.0 g of 1,3-propylene glycol, 0.18 g of allantoin, 0.5 g of magnesium s...

Embodiment 2

[0054] A low-viscosity liquid foundation provided by the present invention is made of A-phase components, B-phase components, C-phase components and D-phase components, based on 100 g of the total mass of the foundation liquid,

[0055] The components of phase A and their contents are as follows: 0.4 g of distearyldimethylammonium hectorite, 3.0 g of polydimethylsiloxane / vinyl polydimethylsiloxane crosslinked polymer , Propylene Carbonate 1.0g, Lauryl PEG-10 Tris(trimethylsiloxy)silylethyl methicone 2.5g, Polyglyceryl-2 Dipolyhydroxystearate 0.5g, PEG / PPG -18 / 18 Dimethicone 1.5g, Isohexadecane 5.0g, Isopropyl Myristate 4.0g, Dimethicone 1.0g, Dimethiconol 3.0g , caprylic / capric triglyceride 4.5g, tocopheryl acetate 2.0g, titanium dioxide 6.5g; iron oxide color powder 1.0g; magnesium stearate 0.5g;

[0056] The various substances and contents of the phase B components are as follows: 10.0 g of glycerin, 5.0 g of 1,3 propylene glycol, 0.22 g of allantoin, 0.5 g of magnesium sul...

Embodiment 3

[0060] A low-viscosity liquid foundation provided by the present invention is made of A-phase components, B-phase components, C-phase components and D-phase components: based on 100 g of the total mass of the foundation liquid,

[0061] The various substances and contents of the phase A components are as follows: 0.8 g of distearyldimethylammonium hectorite, 2.2 g of polydimethylsiloxane / vinyl polydimethylsiloxane crosslinked polymer , Propylene Carbonate 1.8g, Lauryl PEG-10 Tris(trimethylsiloxy)silylethyl Methicone 1.5g, Polyglyceryl-2 Dipolyhydroxystearate 1.2g, PEG / PPG -18 / 18 Dimethicone 0.8g, Isohexadecane 7.0g, Isopropyl Myristate 3.0g, Dimethicone 1.5g, Dimethiconol 2.5g , caprylic / capric triglyceride 5g, tocopheryl acetate 1.8g, titanium dioxide 8g; iron oxide color powder 0.9g; magnesium stearate 0.8g;

[0062] The various substances and contents of the phase B components are as follows: 9.0 g of glycerin, 7.0 g of 1,3-propylene glycol, 0.20 g of allantoin, 0.8 g of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com