Compound camphor and menthol ointment and preparation method thereof

A technology of salicylate and camphor, applied in the field of medicine, can solve the problems of uneven distribution of main drug components, ineffectiveness of creams, easy instability of creams, etc., and achieves improvement of stability and penetration, promotion of stability, and preparation of The method is simple and easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a kind of preparation method of above-mentioned camphor mint salicyl ester emulsifiable paste, it comprises:

[0042] S1. Stir and mix the water-based auxiliary material, carbomer and water at 20-30r / min to obtain the water phase.

[0043] It is preferably mixed in a water phase tank, and the operation is simple and convenient.

[0044] Specifically, the mixing steps of the aqueous phase are as follows:

[0045]Mix water edetate disodium and ethylparaben first, add carbomer under stirring state, overnight, so that carbomer fully swells and dissolves. After filtering, for example, the filtrate can be transferred to an emulsification tank under reduced pressure, and sorbitol and triethanolamine are added to the filtrate under the condition that the stirring rate is 20-30r / min, and after continuing to stir for 5 minutes, heat to 65-75 ℃.

[0046] Optionally, after heating to 65-75°C, it is mixed with dimethyl sulfoxide and edetate dis...

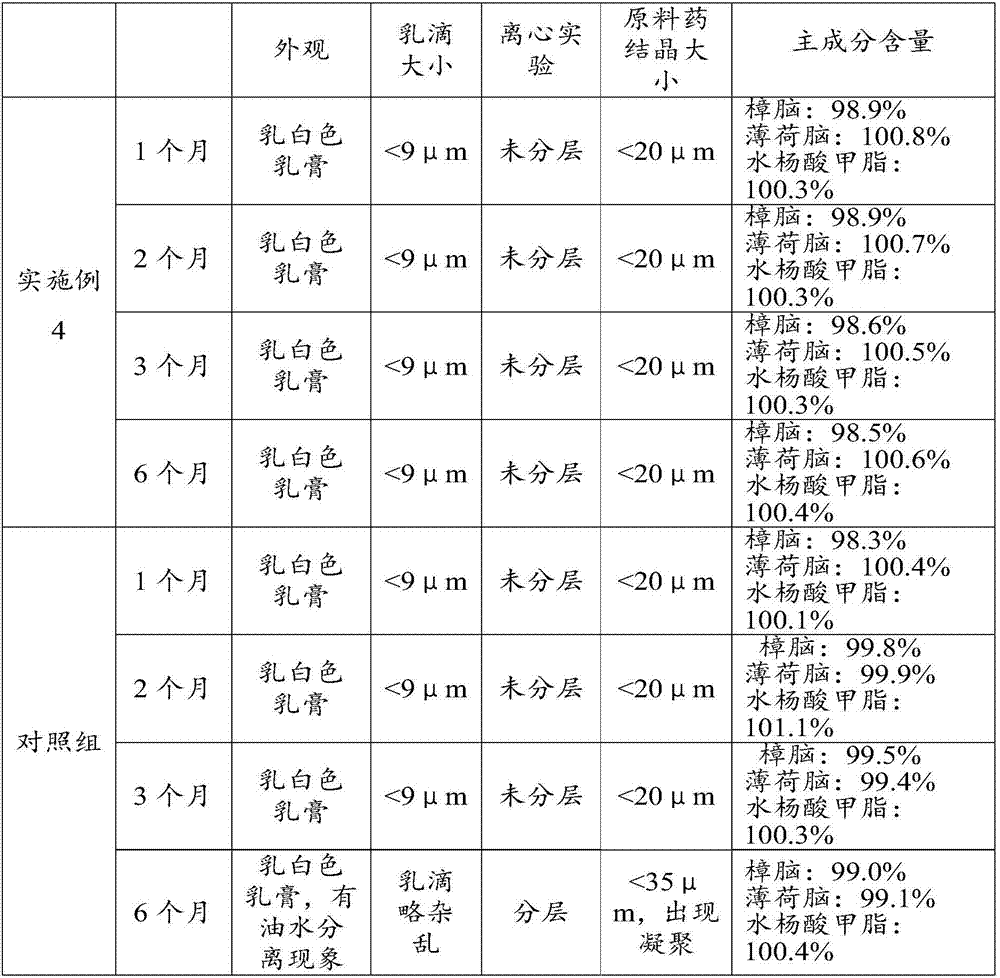

Embodiment 1

[0056] A kind of camphor mint salicyl ester emulsifiable paste, it is made by following method:

[0057] S1. Mix water-based auxiliary materials, carbomer and water, specifically: first mix disodium ethylenediamine tetraacetate and ethylparaben, add carbomer under stirring state, overnight, filter, add to the filtrate Add sorbitol and triethanolamine under the condition that the stirring rate is 25r / min, continue stirring for 5 minutes, and then heat to 65°C.

[0058] Wherein, the water-based auxiliary materials include disodium edetate, ethylparaben, sorbitol and triethanolamine in a weight ratio of 0.015:0.015:15:1.2 in sequence.

[0059] S2. Mix the oil-based auxiliary materials at 74°C and keep warm for 28 minutes to obtain the oil phase.

[0060] The oil-based excipients include stearic acid, glyceryl stearate and polyethylene glycol stearate, pinpina, stearyl alcohol and cetyl alcohol in a weight ratio of 8:3:3:3:2.

[0061] S3. Methyl salicylate, menthol and camphor w...

Embodiment 2

[0065] A kind of camphor mint salicyl ester emulsifiable paste, it is made by following method:

[0066] S1. Mix water-based auxiliary materials, carbomer and water, specifically: first mix disodium ethylenediamine tetraacetate and ethylparaben, add carbomer under stirring state, overnight, filter, add to the filtrate Add sorbitol and triethanolamine under the condition that the stirring rate is 20r / min, continue stirring for 5 minutes, and then heat to 68°C.

[0067] Among them, the water-based auxiliary materials include disodium edetate, ethylparaben, sorbitol and triethanolamine in a weight ratio of 0.02:0.015:14:1.5 in sequence.

[0068] S2. Mix oil-based auxiliary materials at 76°C and keep warm for 30 minutes to obtain an oil phase.

[0069] The oil-based excipients include stearic acid, glyceryl stearate and macrogol stearate, pinpina, stearyl alcohol and cetyl alcohol in a weight ratio of 7:2:2:2.5:2.5.

[0070] S3. Methyl salicylate, menthol and camphor were mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com