Low-smoke antistatic laser-markable ABS composite material

A composite material and laser marking technology, which is applied in the field of modified plastics, can solve problems such as hidden dangers of smoke and dust adsorption, lack of antistatic function, material performance attenuation, etc., and achieve the effect of avoiding a large decrease in mechanical properties and reducing the generation of a large amount of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

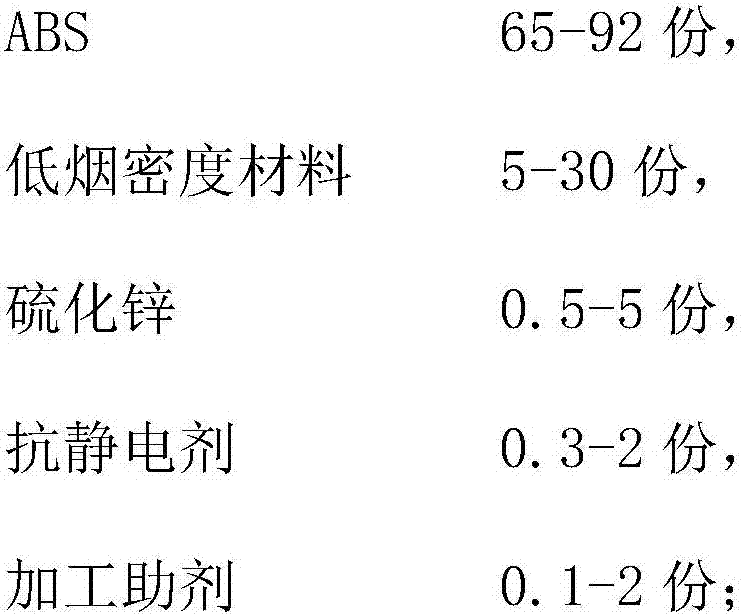

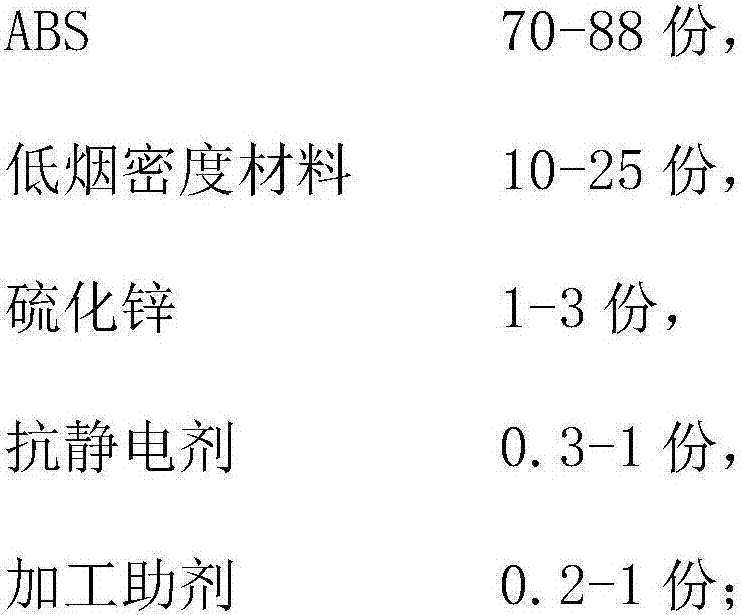

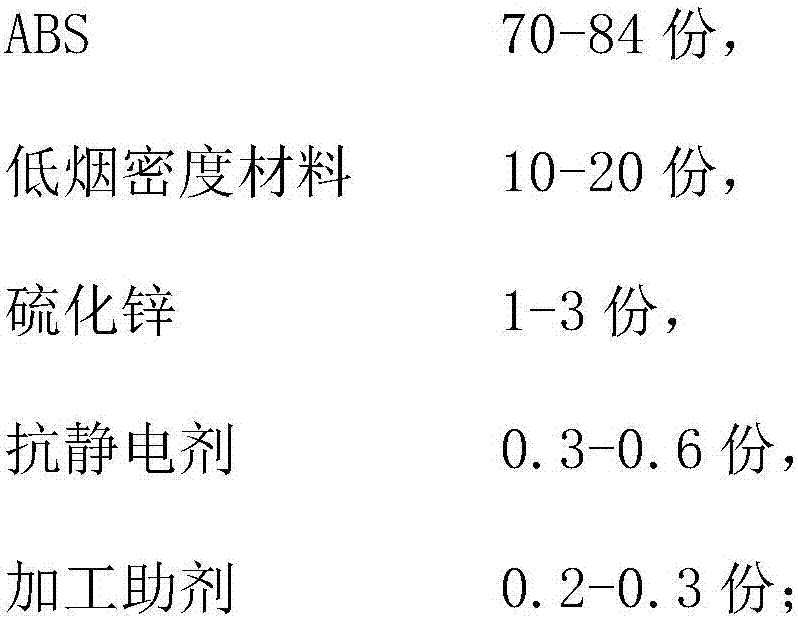

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the low-smoke, antistatic, and laser-markable ABS composite material comprises the following steps: uniformly mixing the raw materials, and then feeding them from the main feeding port of the extruder, where the raw materials are melted, The low-smoke, antistatic and laser-markable ABS composite material is obtained after extrusion and granulation.

[0035] The extruder is a twin-screw extruder. The temperature of the melting step is 190-230°C.

[0036] The processing conditions of the melting step are as follows: the temperature in the first zone is 170-190°C, the temperature in the second zone is 200-220°C, the temperature in the third zone is 200-220°C, the temperature in the fourth zone is 200-220°C, the temperature in the fifth zone is 210-230°C, The temperature in the sixth zone is 210-230°C, the temperature in the seventh zone is 210-230°C, the temperature in the eighth zone is 210-230°C, the temperature in the ninth zone is 200-220°C, ...

Embodiment 1-4

[0039] In the low-smoke, antistatic, laser-markable ABS composite material: the low-smoke density material is methyl methacrylate-acrylonitrile-butadiene-styrene copolymer; the antistatic agent It is glycerol monostearyl ester; the ABS is bulk method ABS; the antioxidant is antioxidant 1010; and the lubricant is ethylene bis stearamide (EBS).

[0040] The preparation method of the low-smoke, antistatic, and laser-markable ABS composite material comprises the following steps: uniformly mixing the raw materials, and then feeding them from the main feeding port of the extruder, where the raw materials are melted, The low-smoke, antistatic and laser-markable ABS composite material is obtained after extrusion and granulation. Please refer to Table 1 for specific data.

[0041] The extruder is a twin-screw extruder. The temperature of the melting step is 190-230°C.

[0042] The processing conditions of the melting step are as follows: the temperature in the first zone is 170-190°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com